Super-thick material layer pre-sintering device and using method thereof

A technology of pre-sintering and thick material layer, applied in the field of sintering, can solve the problem of inability to carry out the pre-sintering process and research of ultra-thick material layer, and achieve the effects of increasing the capacity of sintered ore, improving the quality uniformity, improving the strength and the yield of the finished product.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

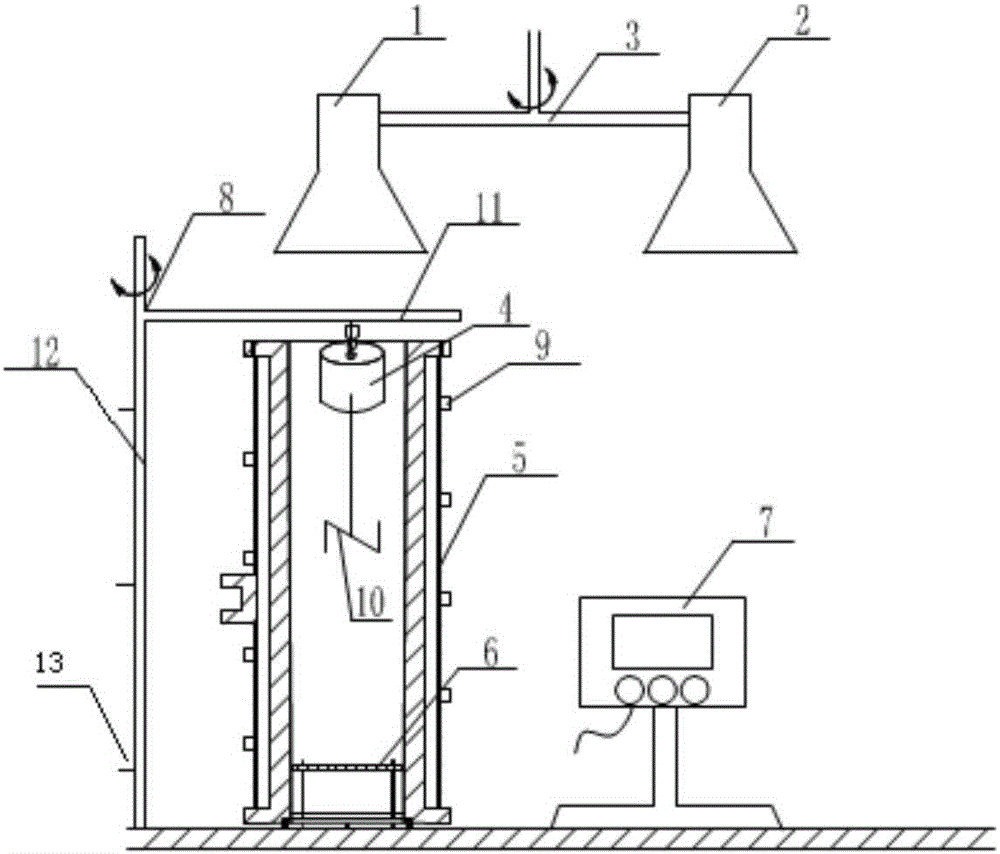

[0029] An ultra-thick material layer pre-sintering device, such as figure 1 shown. The inner diameter of the sintering cup is 330mm, the height is 1000mm, and the temperature measuring thermocouples are distributed along the height direction. Equipped with material level testing system, including anti-rotation material level gauge 4, connected to its rotating lifting device 8 marked with a scale, the initial position of the scale is kept level with the upper end of the grate in the sintering cup body, which can automatically detect the sintering mixture in the sintering cup body material surface height. The igniter includes 1# igniter 1, 2# igniter 2, 1#2# igniter rotary lifting connection device 3 can be rotated and lifted arbitrarily, which can realize the use of different igniters for the first and second ignition, improve production efficiency and can Extend igniter life.

[0030] A method of using an ultra-thick material layer pre-sintering device. First, the material ...

Embodiment 2

[0035] An ultra-thick material layer pre-sintering device, such as figure 1 shown. The inner diameter of the sintering cup is the sintering cup test device, the inner diameter of the sintering cup is 330mm, the height is 1200mm, and the temperature measuring thermocouples are distributed along the height direction. Equipped with material level testing system, including anti-rotation material level gauge 4, connected to its rotating lifting device 8 marked with a scale, the initial position of the scale is kept level with the upper end of the grate in the sintering cup body, which can automatically detect the sintering mixture in the sintering cup body material surface height. The igniter includes 1# igniter 1, 2# igniter 2, 1#2# igniter rotary lifting connection device 3 can be rotated and lifted arbitrarily, which can realize the use of no igniter for the first and second ignition, improve production efficiency and can Extend igniter life.

[0036] A method of using an ult...

Embodiment 3

[0041] An ultra-thick material layer pre-sintering device, such as figure 1 shown. The inner diameter of the sintering cup is the sintering cup test device, the inner diameter of the sintering cup is 330mm, the height is 1600mm, and the temperature measuring thermocouples are distributed along the height direction. Equipped with material level testing system, including anti-rotation material level gauge 4, connected to its rotating lifting device 8 marked with a scale, the initial position of the scale is kept level with the upper end of the grate in the sintering cup body, which can automatically detect the sintering mixture in the sintering cup body material surface height. The igniter includes 1# igniter 1, 2# igniter 2, 1#2# igniter rotary lifting connection device 3 can be rotated and lifted arbitrarily, which can realize the use of no igniter for the first and second ignition, improve production efficiency and can Extend igniter life.

[0042] A method of using an ult...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com