A processing method for flame-retardant treatment of narrow-width fabrics

A technology of flame retardant treatment and processing method, which is applied in the processing of textile materials, liquid/gas/steam textile material processing, fiber processing, etc. and other problems, to achieve the effect of good flame retardant properties, stable flame retardant properties and strong durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

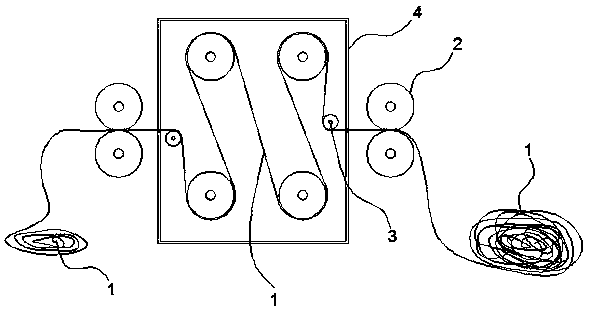

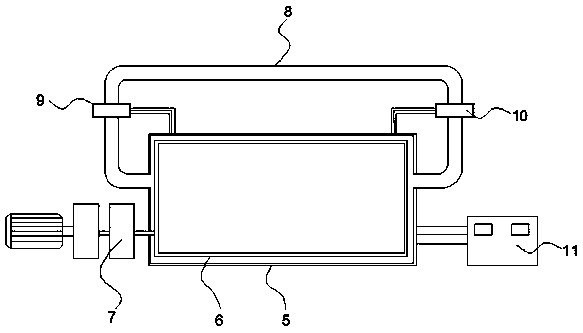

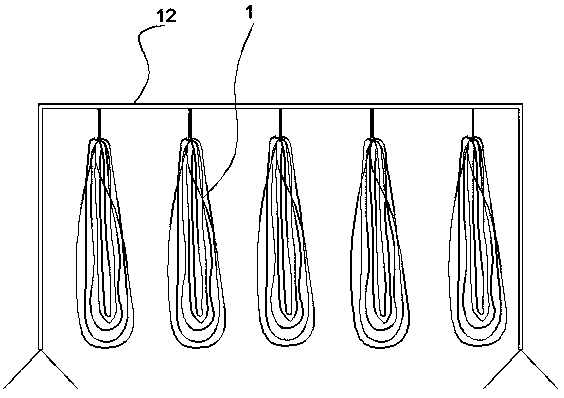

[0037] A processing method for flame-retardant treatment of narrow-width fabrics, combined with an attached Figure 2-3 The special equipment shown specifically includes the following processing steps: 1.1 The narrow fabric to be treated is fully immersed in a container with a flame retardant and kept for 60 minutes; the flame retardant consists of 6 parts by mass of diamine hydrogen phosphate, 8 Parts by mass of trimethyloltripolyamide, 4 parts by mass of tetrahydroxyethyl phosphorus chloride, 11 parts by mass of sodium silicate, 25 parts by mass of magnesium hydroxide, 30 parts by mass of aluminum hydroxide, and the others are triphenyl phosphate ester composition and the temperature of the flame retardant is 40°C.

[0038] 1.2 Take out the narrow-width fabric soaked in the flame retardant in step 1.1 and put it into a dehydration device for dehydration treatment; the dehydration device rotates at 1200 rpm, and the continuous dehydration time is kept for 5 minutes.

[0039]...

Embodiment 2

[0050] A processing method for flame-retardant treatment of narrow-width fabrics, combined with an attached Figure 2-3 The special equipment shown specifically includes the following processing steps: 1.1 The narrow fabric to be treated is completely immersed in a container containing a flame retardant and kept for 60 minutes; the flame retardant is composed of 5 parts by mass of diamine hydrogen phosphate, 6 Parts by mass of trimethyloltripolyamide, 3 parts by mass of tetrahydroxyethyl phosphorus chloride, 8 parts by mass of sodium silicate, 20 parts by mass of magnesium hydroxide, 20 parts by mass of aluminum hydroxide, and the others are triphenyl phosphate ester composition and the temperature of the flame retardant is 30°C.

[0051] 1.2 Take out the narrow-width fabric soaked in the flame retardant in step 1.1 and put it into a dehydration device for dehydration treatment; the dehydration device rotates at 1000 rpm, and the continuous dehydration time is kept for 8 minut...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com