Manhole cover planning-milling device

A planing and milling and manhole cover technology, which is applied in roads, road repairs, roads, etc., can solve the problems of limited deformation resistance of joint materials and difficulty in improving waterproof performance, and achieve flexible and convenient planing and milling depth, improve deformation resistance, and good The effect of water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

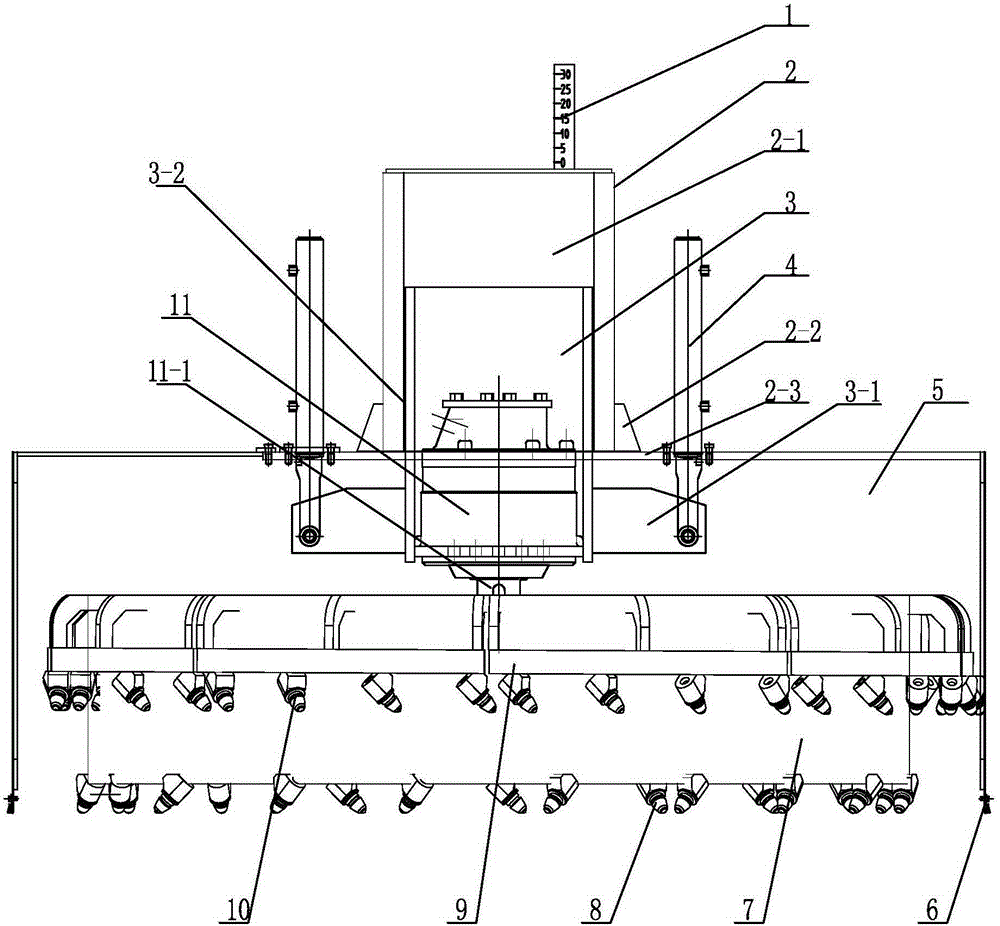

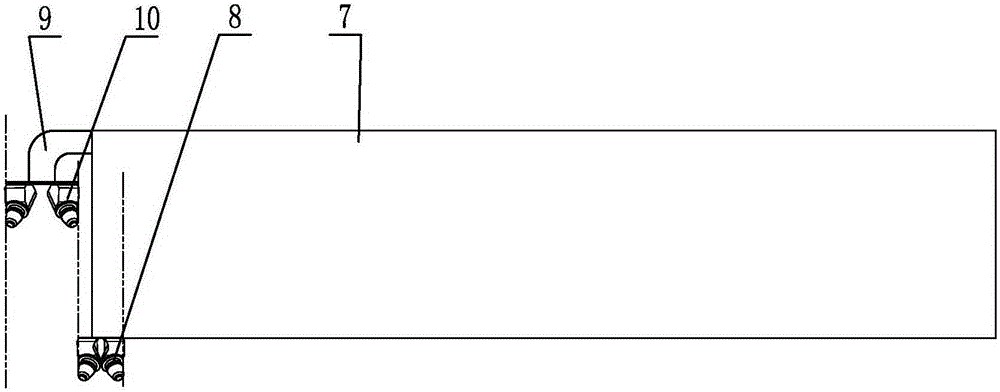

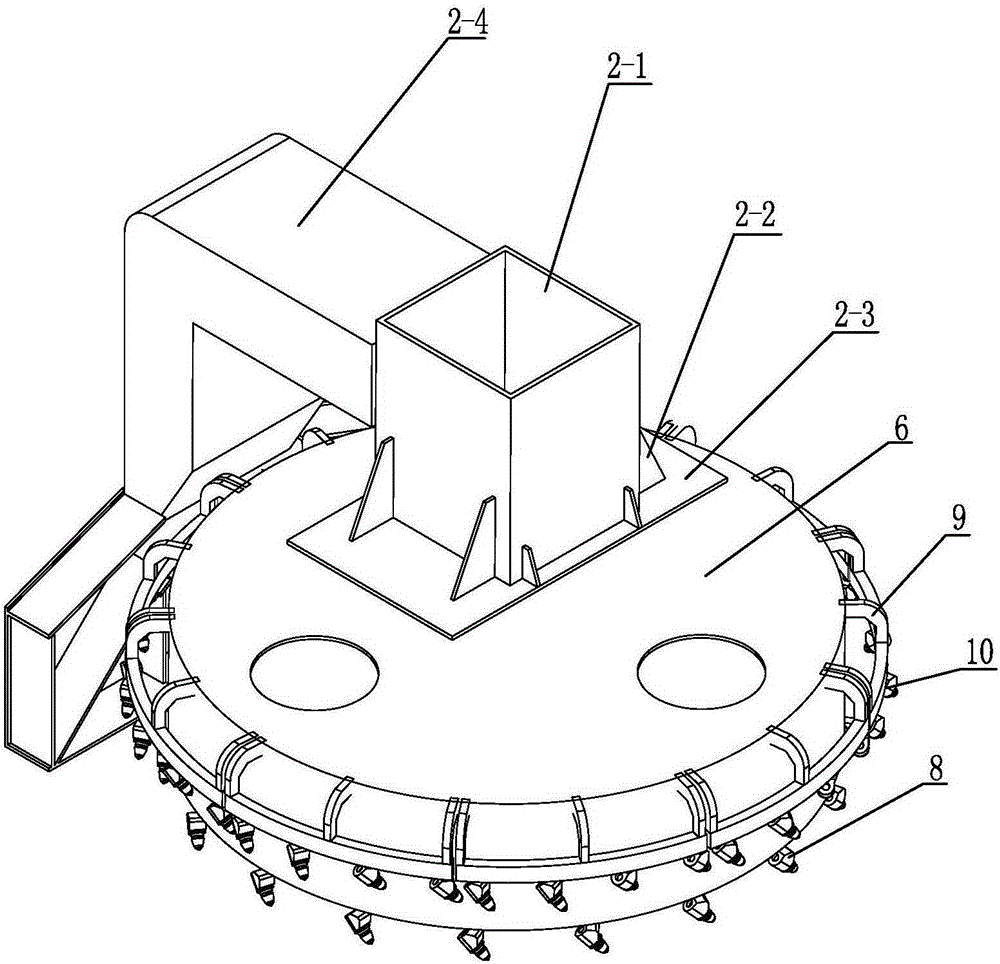

[0018] See Figure 1~3 As shown, the manhole cover planing and milling device of the present invention includes a frame 2, a mounting seat 3 that can move up and down along the frame 2 and is used to install a hydraulic motor 11, the frame 2 is connected with a motor vehicle, and is passed through the first motor vehicle. The working cylinder 13 and the second working cylinder 14 are connected with the frame 2 to control the overall movement of the manhole cover planing and milling device and to keep the cutter head on the frame level with the ground.

[0019] See figure 1 As shown, a hydraulic motor 11 is installed on the lower part of the mounting seat 3 of the present invention, the output shaft 11-1 of the hydraulic motor 11 is connected with the cutter head assembly, and the output shaft 11-1 of the hydraulic motor 11 is connected with the cutter head 7 to drive the cutter head 7 Rotate to drive the cutter head to plan and mill the road surface. See figure 1 As shown, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com