Deposited carbon regeneration and thermal fatigue simulation testing system of diesel fuel particulate trap

A particle trap and simulation testing technology, which is applied in the testing of machine/structural components, testing of mechanical components, instruments, etc., can solve the problem that the engine bench cannot be developed and tested by DPF, and the cost of the engine test bench is high. Engine development Time cycle and other issues, to achieve the effect of simplifying user testing process and reducing system investment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in detail below in terms of specific embodiments in conjunction with the accompanying drawings. The following examples will help those skilled in the art to further understand the present invention, but do not limit the present invention in any form. It is to be noted that other embodiments may be utilized or structural and functional modifications may be made to the embodiments set forth herein without departing from the scope and spirit of the invention.

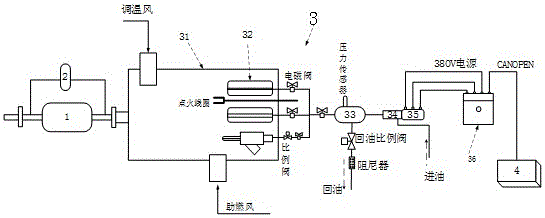

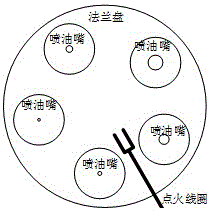

[0034] The burner is a combustion system that mixes fuel and air for combustion to provide high-temperature gas. Divided into several types such as industrial, civil and special. The burner simulation device 3 in this embodiment is a device for simulating a dedicated burner for an automobile exhaust system and after-treatment components.

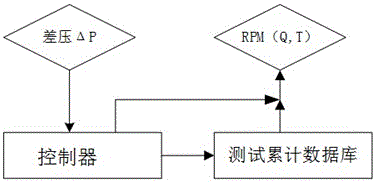

[0035] The Diesel Particulate Filter 1 (Diesel Particulate Filter) in this embodiment is an exhaust post-treatment device installed in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com