A roadbed dynamic loading model test system

A technology of model testing and subgrade dynamics, applied in the direction of applying repetitive force/pulsation force to test material strength, applying stable tension/compression to test material strength, instruments, etc., can solve problems such as inability to accurately simulate train loads

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention is described in detail below with reference to accompanying drawing and specific embodiment

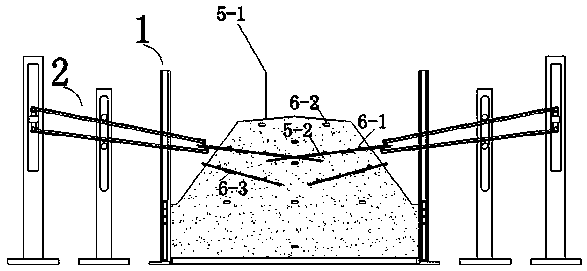

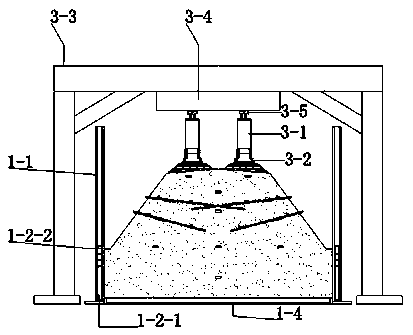

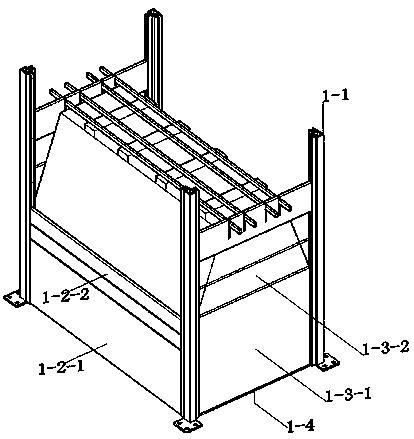

[0043] A roadbed dynamic loading model test system is composed of a test box 1, two sets of reinforcement pile embedding devices 2, a loading device 3, and two sets of braking devices 4.

[0044] 1) The test chamber 1 consists of at least four steel pipe columns 1-1, two main side panels A1-2-1 arranged along the driving direction of the roadbed model, several auxiliary side panels A1-2-2, and a vertical roadbed model driving direction. Two main side plates B1-3-1 and several auxiliary side plates B1-3-2 arranged in the direction, two connecting channel steels 1-4 connecting the bottom ends of the two steel pipe columns 1-1 horizontally, embedded in the steel pipe column 1 -1 or the rubber pad 1-5 between the connecting channel steel 1-4 and the side plate B1-3. When the subgrade model 5-1 is longitudinally long, in order to prevent excessive deformation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com