Mask filtering performance tester

A filter performance test and mask technology, which is applied in the direction of measuring devices, scientific instruments, suspension and porous material analysis, etc., can solve the problems of inconvenient use of large equipment, large volume, high price, etc., to reduce the cost of testing, small size, Portable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention is described in further detail below:

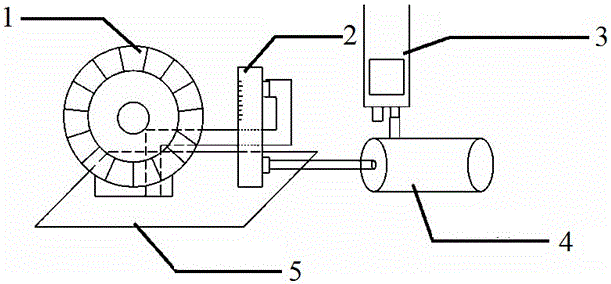

[0017] Such as figure 1 A mask filtration performance tester shown is composed of a vacuum pump 1, a flow meter 2, a particle counter 3, a test pipeline 4, and a base 5. The vacuum pump is installed on the base, the flow meter is located between the vacuum pump and the test pipeline, the flow meter is respectively connected with the vacuum pump and the test pipeline, and the test pipeline is also connected with a particle counter.

[0018] Wherein, the vacuum pump 1 and the flowmeter 2 are connected through a PVC steel wire hose with a diameter of 30mm; the flowmeter 2 and the test pipeline 4 are connected through a PU hose with a diameter of 12mm The thin hose is connected, and the interface is fastened with an easy-to-detach pneumatic joint with a diameter of 12mm. The test pipe 4 is connected to the particle counter 3 through a thin PU hose with a diameter of 12 mm, and the interface is fastened with a m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com