Fault oscilloscope working condition information remote monitoring, maintenance and rapid browsing system

A technology of fault recorder and working condition information, which is applied in the fault location and detection of faults according to conductor types, etc., can solve the problems of insufficient on-site coordination of fault recorder and no on-site inspection, and achieves low construction cost, The effect of low load bearing and reduction of failure loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

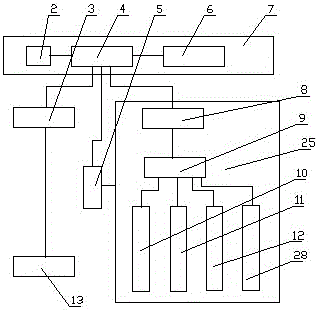

[0029] Such as Figure 1 to Figure 4 As shown: this embodiment provides a remote monitoring, maintenance and quick browsing system for fault recorder working condition information, including several fault recorders 13 arranged on the transmission line, a monitoring center 7 and a mobile device connected to it Type monitoring unit, described mobile monitoring unit comprises the overhead rail 16 that is arranged along grid line, the rail car 24 that is arranged on described overhead rail 16 and positioning device 5, the monitoring terminal 25 that is set on described rail car 24, described monitoring The terminal 25 includes a sensor module 10, a control module 9, a video monitoring module 11, a first communication module 8 and a UHF omnidirectional sensor receiving and amplifying module 12 that is rotatably arranged on the rail car, and the control module 9 and the sensor module 10, The video monitoring module 11, the first communication module 8 are connected with the UHF omni...

Embodiment 2

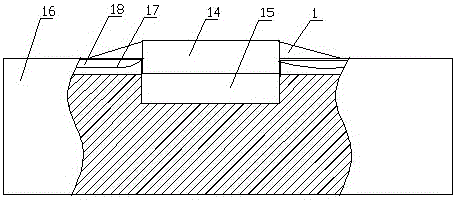

[0037] Such as Figure 1 to Figure 4 Shown: its difference with embodiment one is:

[0038] The positioning device 5 includes several sensor slots 15 arranged at intervals on the overhead track 16, and fiber grating sensors 14 are arranged in the sensor slots 15, and the several fiber grating sensors 14 are connected by transmission optical fibers 17. The top of the fiber grating sensor 14 is higher than the upper edge of the sensor groove 15 , and the transmission optical fiber 17 is arranged in the cavity 18 arranged on the overhead track 16 . The fiber grating sensor can realize the direct measurement of physical quantities such as temperature and strain. When the wheel of the traveling mechanism is pressed on the fiber grating sensor, it will be strained, so that it is detected whether the traveling mechanism reaches the top of the fiber grating sensor, thus realizing the fixed-point Radiation measurement.

[0039] The top of the fiber grating sensor 14 is 0.5 cm to 1 cm...

Embodiment 3

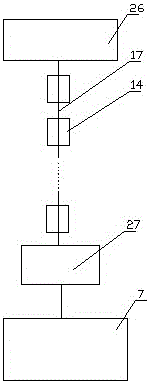

[0043] Such as Figure 1 to Figure 4 Shown: its difference with embodiment one is:

[0044] The hanging mechanism comprises an L-shaped bracket 32 provided at the lower end of the rail car 24 and two U-shaped arms 30 arranged at the upper end of the aircraft 28, and the open end of the L-shaped bracket 32 is provided with a telescopic frame at the lower end of the rail car 24. Rod 29, the telescopic rod 29 is connected with the control module 9, and the aircraft 28 adopts a quadrotor UAV. When the aircraft is not in use, it is hung on the L-shaped bracket through two U-shaped arms, and then the opening of the L-shaped bracket is blocked by the telescopic rod to prevent the U-shaped arm from slipping off the L-shaped bracket. When in use, the telescopic control is controlled by the control module The arm is retracted, and the aircraft can fly out from the L-shaped support. The aircraft adopts a quadrotor drone, the stability of the fuselage is better maintained, and it is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com