Inspection system and inspection method for computer multi-interface production control system

A production control, multi-interface technology, applied in the direction of computer control, general control system, control/regulation system, etc., can solve the problem that the control personnel cannot effectively evaluate the quality of monitoring or control, and achieve the effect of improving the quality of work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

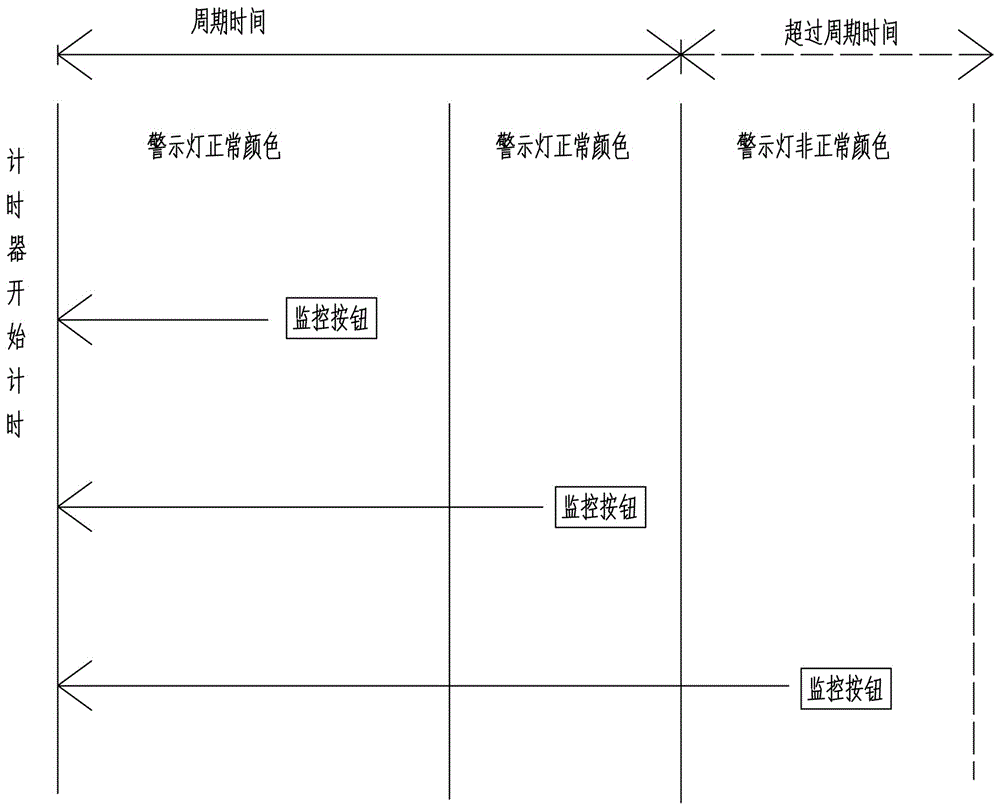

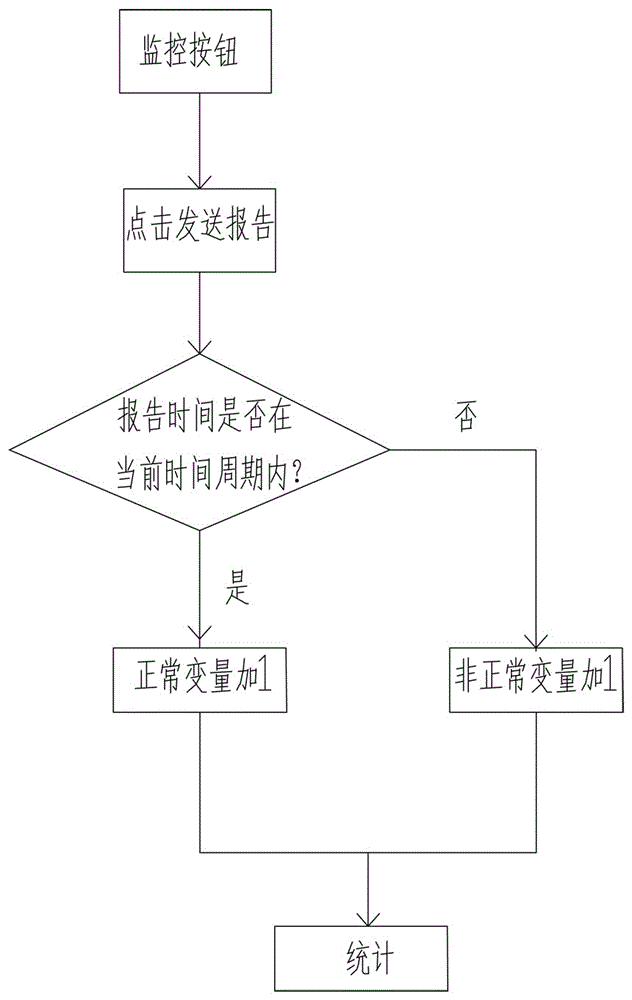

[0035] At present, power plants implement centralized control of boilers, steam turbines and generators, and use distributed control system (DCS) to monitor and control production. For units with a single capacity of 300MW, DCS has more than 40 interfaces, and about 1,000 parameters need to be monitored. Parameter importance, grading the parameters:

[0036] 1. Category A: If the parameter exceeds the limit, catastrophic consequences will occur, and strict monitoring is required, such as main steam pressure, steam turbine speed, boiler drum water level, etc. Set a type A timer on the type A parameter measuring point interface of the DCS interface. The time interval between checking the parameter twice is not more than 5 minutes. When checking the parameter, the timer is cleared at the same time.

[0037] 2. Class B: If the parameter exceeds the limit, it will cause equipment damage, cause the unit to trip, reduce output, etc., such as the bearing temperature, vibration, heater...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com