A single-double continuous coil

A double-continuous and continuous technology, applied in the direction of transformer/inductor coil/winding/connection, electrical components, transformer/inductor parts, etc., can solve the problem of insignificant improvement of hot spots at the end of the coil and reduce the axial size of the wire and other issues, to achieve the effect of increasing the heat dissipation area and heat dissipation capacity, reducing the axial specification of the wire, and compacting the overall size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below in conjunction with the accompanying drawings.

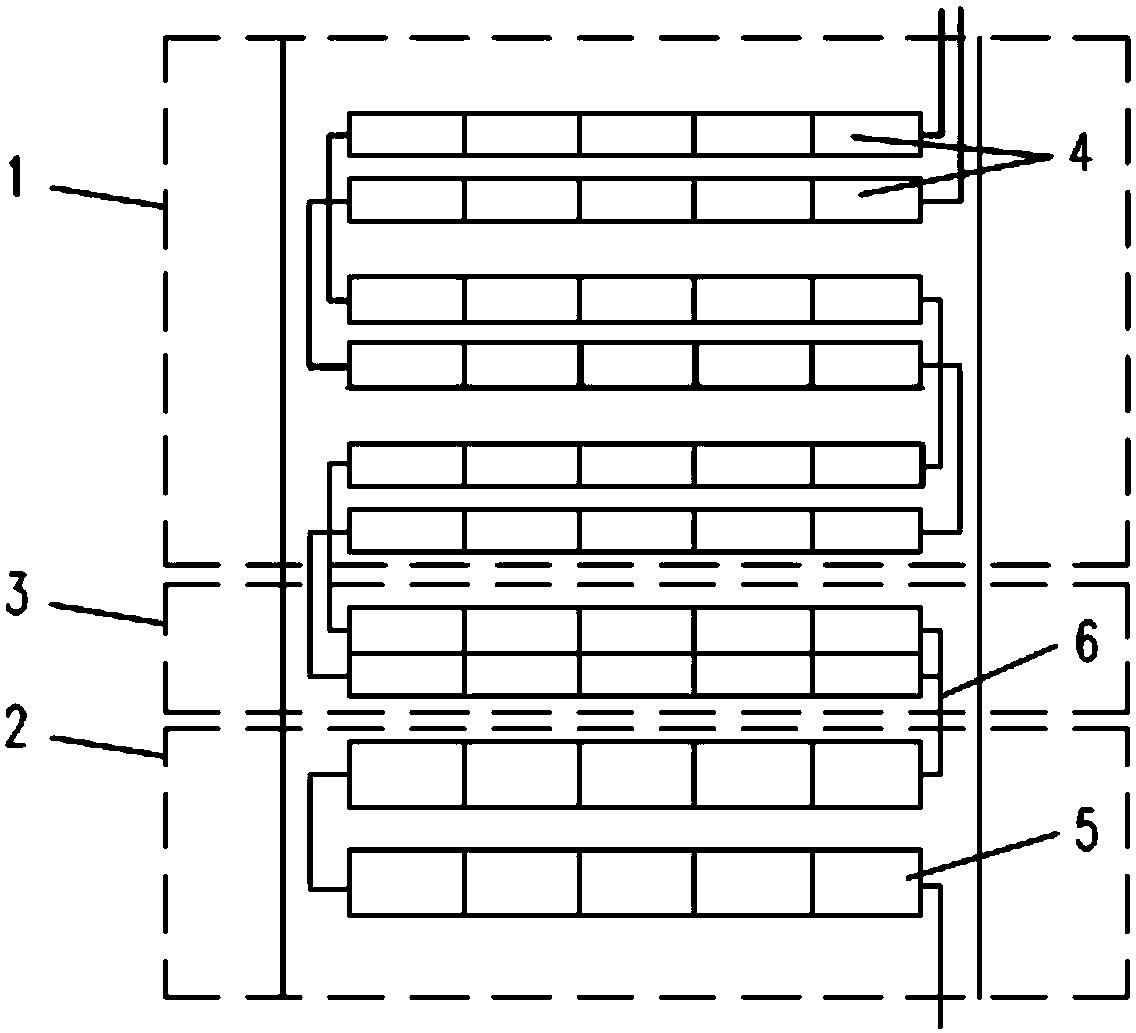

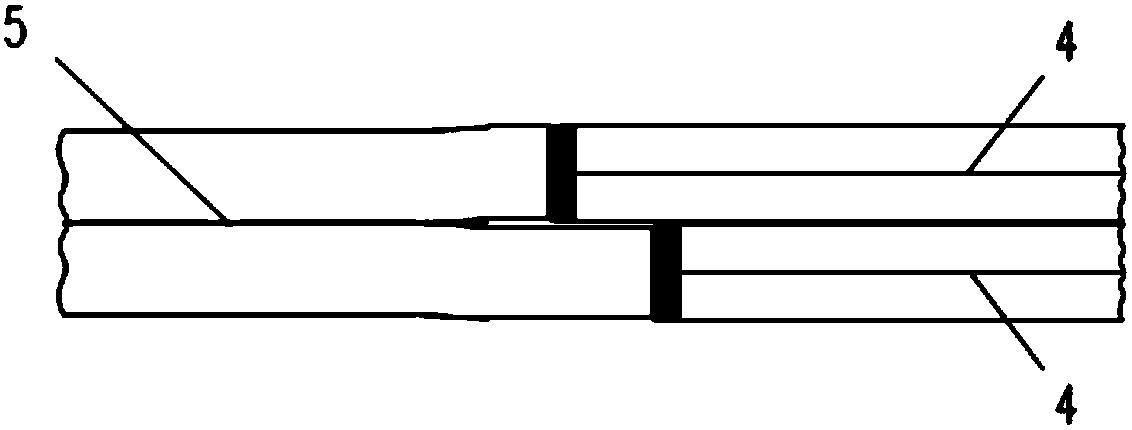

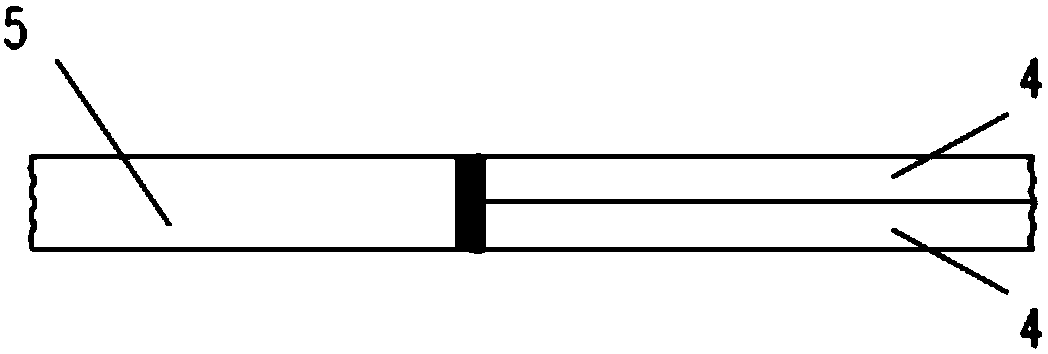

[0018] see figure 1 , the single-double continuous coil provided by the present invention is composed of double continuous wire cake 1, single continuous wire cake 2 and coil transition wire cake 3; the coil type of double continuous wire cake 1 is double continuous, single continuous The coil type of type 2 is single-continuous; the head end of the overall coil is wound as a double-continuous coil, and the other parts are wound as a single-continuous coil; Carry out a transposition in the middle of the line cake 1.

[0019] Please parameter figure 1 As shown, when the single-double continuous coil in the present invention is mainly used to reduce the temperature rise of hot spots, the coils are double continuous coil 1, coil transition coil 3 and single continuous coil 2 from top to bottom; When the single-double continuous coil in the present invention i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com