A kind of binder for positive electrode of lithium-sulfur battery and preparation method thereof

A lithium-sulfur battery and binder technology, applied in battery electrodes, lithium batteries, non-aqueous electrolyte batteries, etc., to achieve enhanced cycle performance, simple method, and easy promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

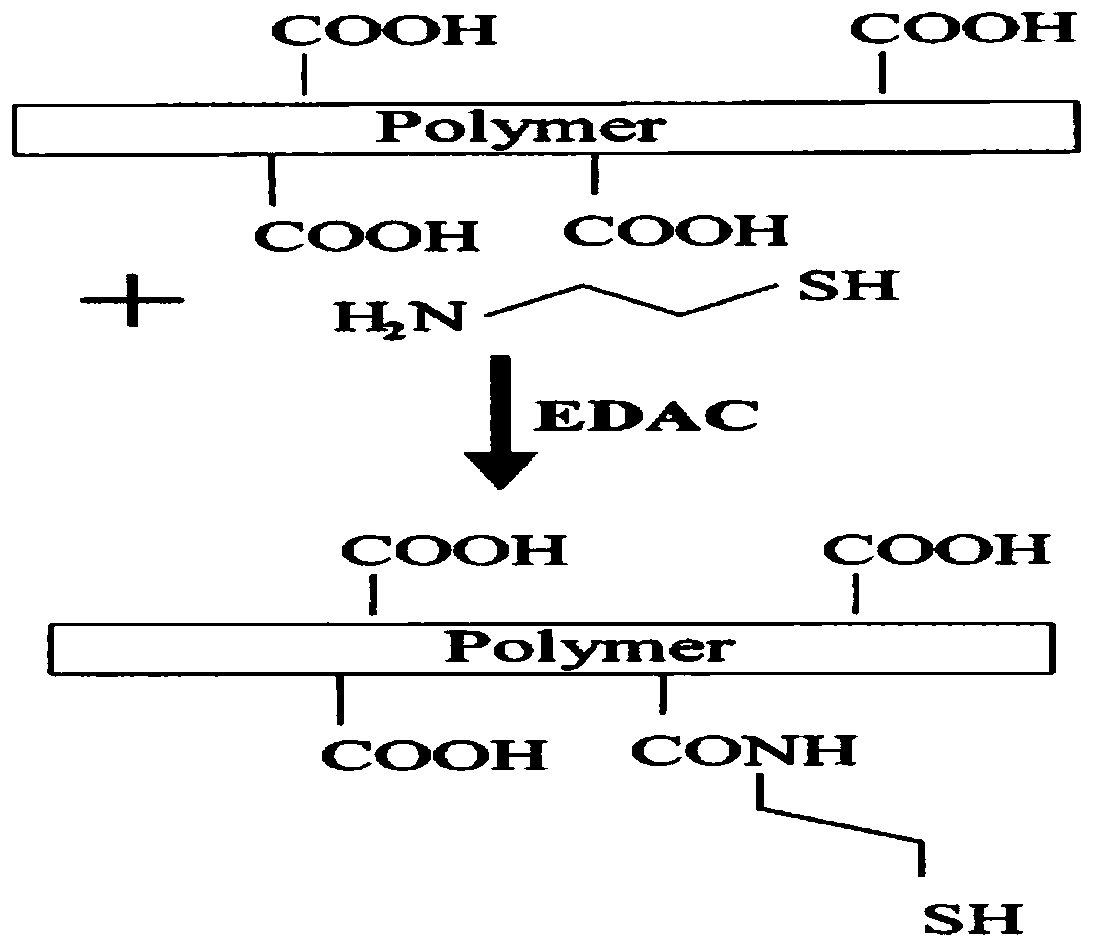

[0041] Preparation of mercaptolated CMC binder: Weigh 2 g of CMC, dissolve it in 200 ml of deionized water, and stir until a uniform and stable solution is formed. Then add EDAC to activate for 30min, then add 0.25g cysteamine to the mixed solution, adjust the solution to PH=4-5 with 1M HCl, then stir at room temperature for 3h, finally dialyze with 1mMHCl and freeze-dry, the obtained product is thiolated CMC, Synthesis process see figure 1 .

Embodiment 2

[0043] 1. Preparation of mercaptolated CMC binder: The preparation of the modified binder in this example is the same as in Example 1

[0044] 2. Preparation of positive electrode sheet: Sulfur-containing active material: acetylene black: modified CMC binder = 8:1:1 ratio, with deionized water as solvent, prepared into slurry, and coated on aluminum foil , the coating film was dried in a vacuum oven at 70° C. for 12 hours, and placed in a glove box for later use.

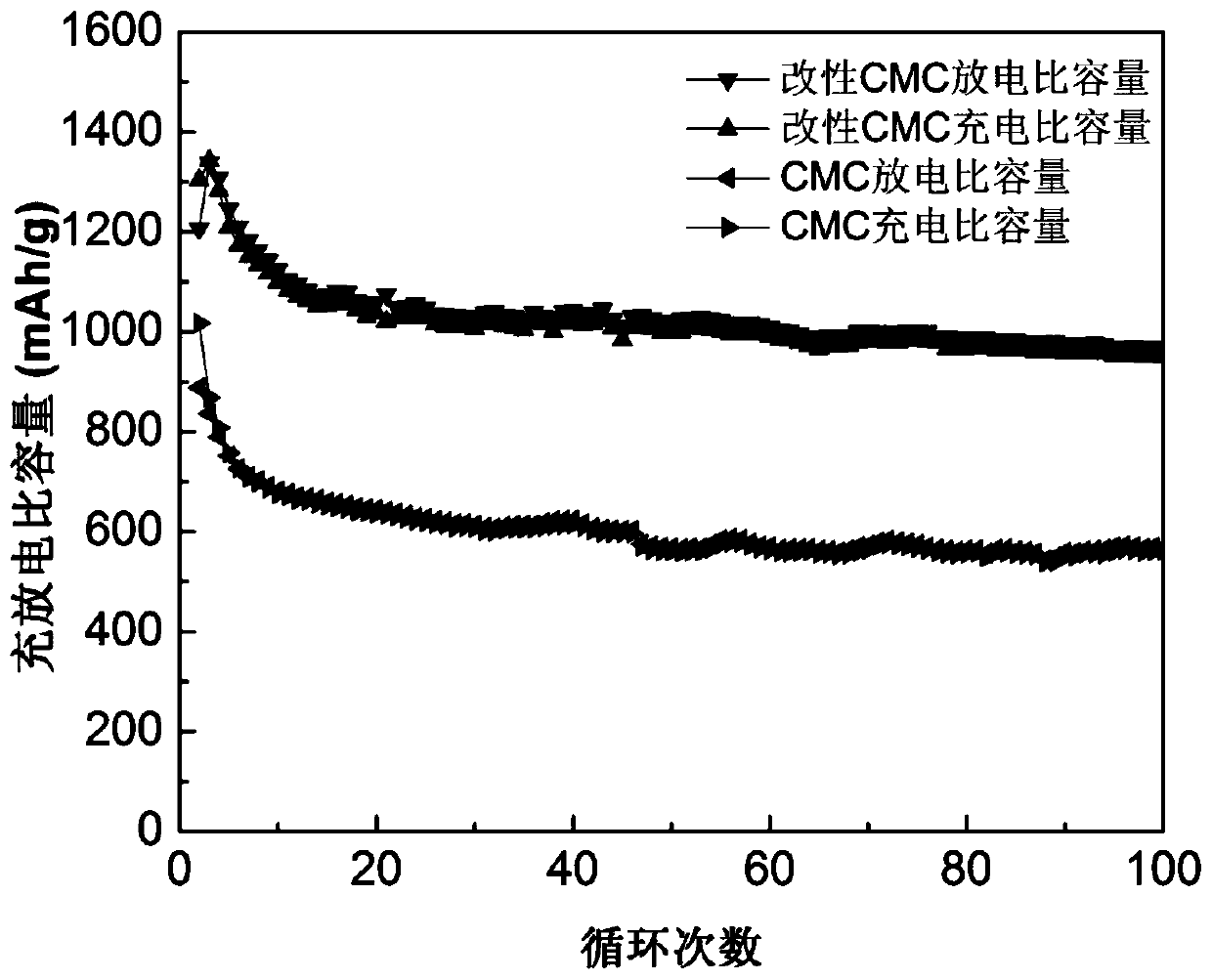

[0045]3. Assembling the button cell: put the diaphragm between the positive and negative electrodes, and then assemble and package the battery. The above operations are all completed in a glove box filled with argon. Lithium-sulfur battery performance see figure 2 .

Embodiment 3

[0047] 1. Preparation of thiolated PAA binder: Weigh 1g of PAA, dissolve it in 150ml of deionized water, and stir until a uniform and stable solution is formed. Then add EDAC to activate for 60min, then add 0.5g cysteine to the mixture, adjust the solution to pH=4-5 with 1M HCl, then stir at room temperature for 4h, finally dialyze with 1mMHCl and freeze-dry, the obtained product is thiolated PAA.

[0048] 2. Preparation of positive electrode sheet: Sulfur-containing active material: acetylene black: mercaptolated PAA binder = 7:2:1 ratio, deionized water as solvent, adjusted to slurry, and coated on aluminum foil , the coating film was dried in a vacuum oven at 70° C. for 12 hours, and placed in a glove box for later use.

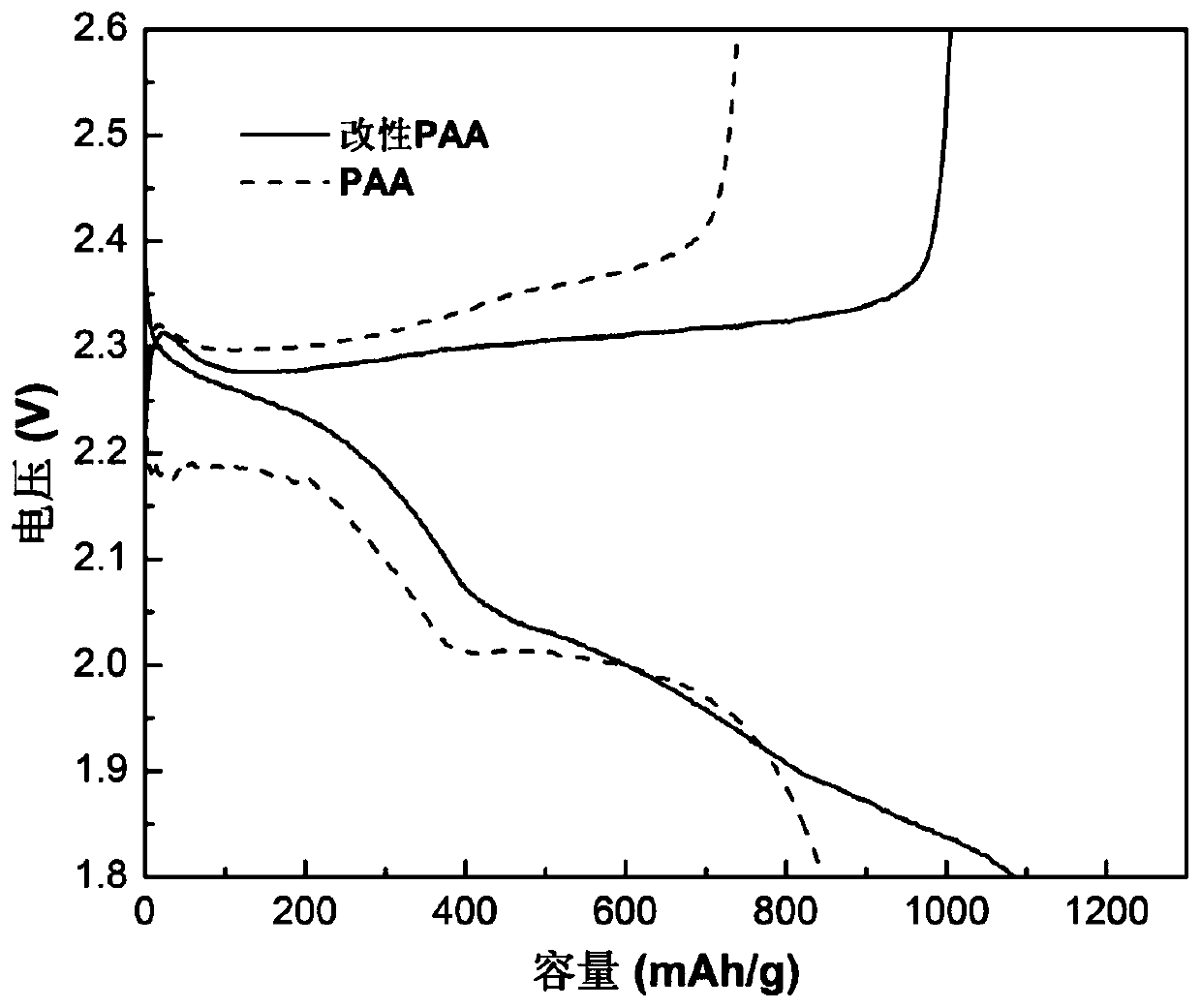

[0049] 3. Assembling the button cell: put the diaphragm between the positive and negative electrodes, and then assemble and package the battery. The above operations are all completed in a glove box filled with argon. Lithium-sulfur battery performance ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com