Electric power conversion device

A technology for power conversion devices and conduits, which is applied to circuit thermal devices, electrical components, printed circuit components, etc., can solve the problems of heat recovery and low heat dissipation efficiency, and achieve the effect of high heat dissipation efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

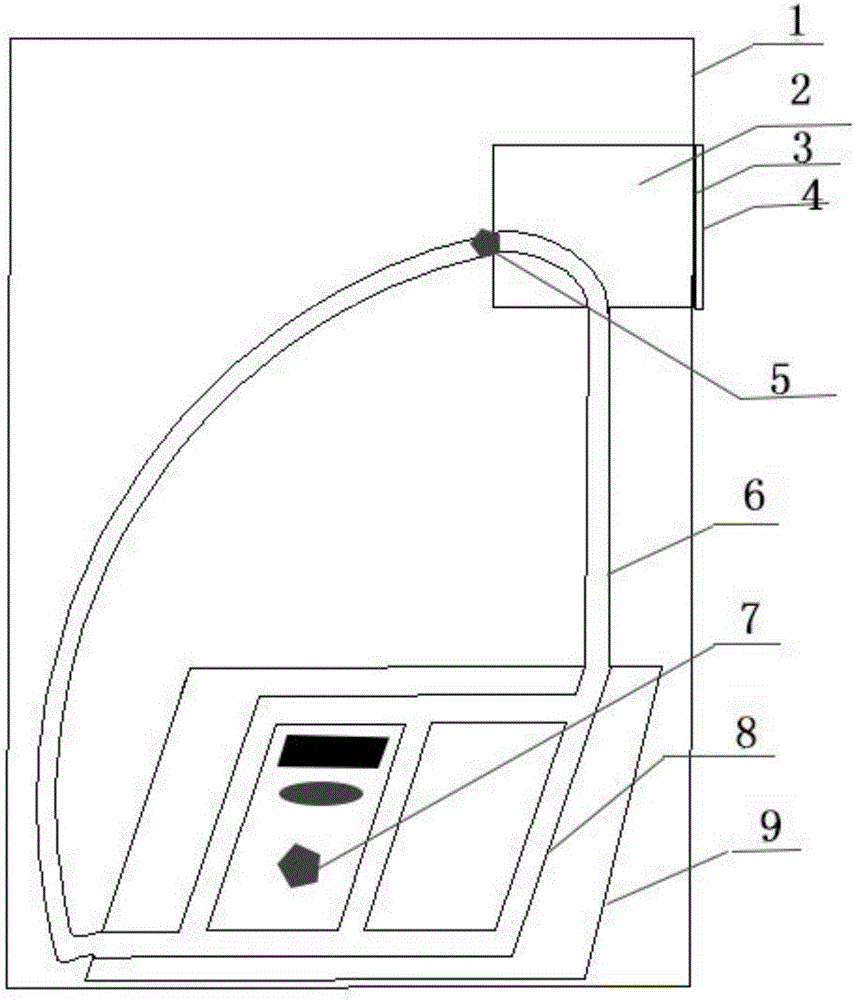

[0017] A power conversion device, comprising a box body 1 and a PCB board 9 on which a plurality of semiconductor devices 7 are installed, characterized in that it includes a plurality of heat-absorbing evaporation channels 8 arranged on the PCB board 9, and a plurality of semiconductor devices 7 are arranged and installed Between two pairs of heat-absorbing evaporation channels 8, a plurality of heat-absorbing evaporation channels 8 are combined and connected to one end of the refrigerant conduit 6, and the other end of the refrigerant conduit 6 is connected to the condensing part 2, and the installation position of the condensing part 2 is 9 positions higher than that of the PCB board. high.

[0018] Preferably, the refrigerant conduit 6 is a non-thermal conduction conduit. It is set as a heat-non-conductive pipe, so that the refrigerant that becomes vapor will not release heat to the inner space of the box before reaching the condensing part, thereby avoiding the return of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com