A limit calibration gauge and a limit calibration method for special gauges for nuclear fuel elements

A technology of nuclear fuel components and calibration gauges, which is applied in the calibration/testing of force/torque/power measuring instruments, nuclear engineering, nuclear power generation, etc. It can solve the problems of inability to trace products, inability to realize real-time control and positioning of measuring tools in use, etc. Achieve the effects of simple and fast calibration, shorten the calibration cycle, and save calibration costs

Active Publication Date: 2015-12-23

CHINA NUCLEAR BAOTOU GUANGHUA CHEM IND

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

When adopting actual measurement method to calibrate, there is following defect: actual measurement method needs aiming and adjustment repeatedly repeatedly, and positioning

There is a risk that unqualified measuring tools may be mistakenly accepted as qualified, and the calibration cycle is one year, so real-time control of measuring tools in use cannot be realized.

If the measuring tool is inaccurate, it may not be possible to trace the product, and the consequences will be serious

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

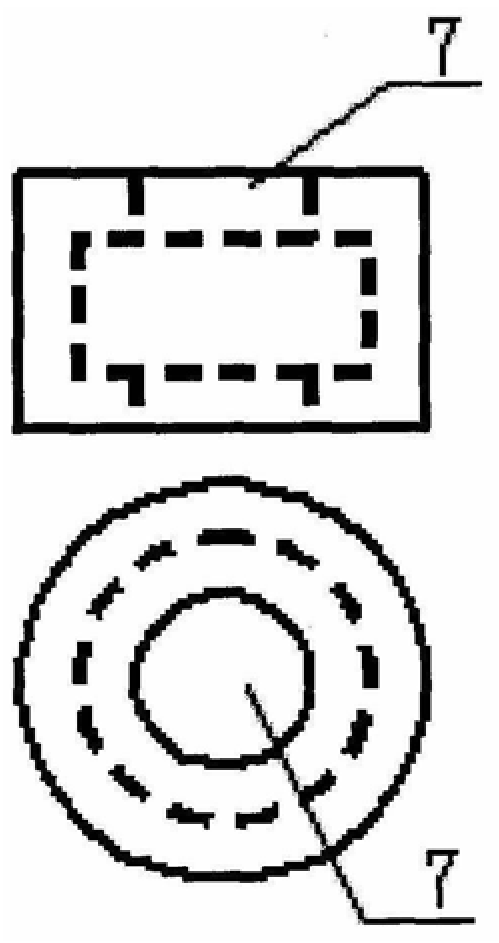

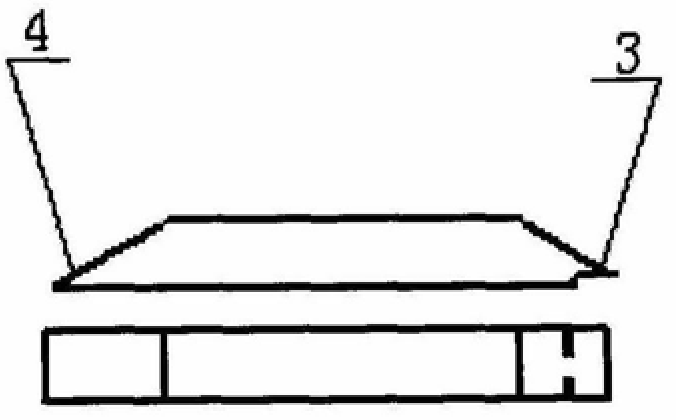

The invention relates to a limit calibration gauge and a limit calibration method which can realize rapid real-time calibration of special measuring tools on site. In the evaluation of the calibration method of the special measuring tool, the present invention realizes the simple and rapid calibration of the special measuring tool production site, shortens the calibration period, and saves the cost of sending out the calibration. In terms of product quality control, the limit calibration method realizes the real-time calibration of special measuring tools, effectively avoids the quality problem of product misjudgment caused by the inaccuracy of special measuring tools, and effectively controls the manufacturing quality of nuclear power fuel elements. (In terms of verification results, through the measurement uncertainty evaluation and calibration capability analysis of the "limit calibration gauge" and "limit calibration method", the calibration capabilities of the limit calibration gauge and the limit calibration method fully meet the requirements of national defense measurement value transfer, On-site real-time calibration can be realized.

Description

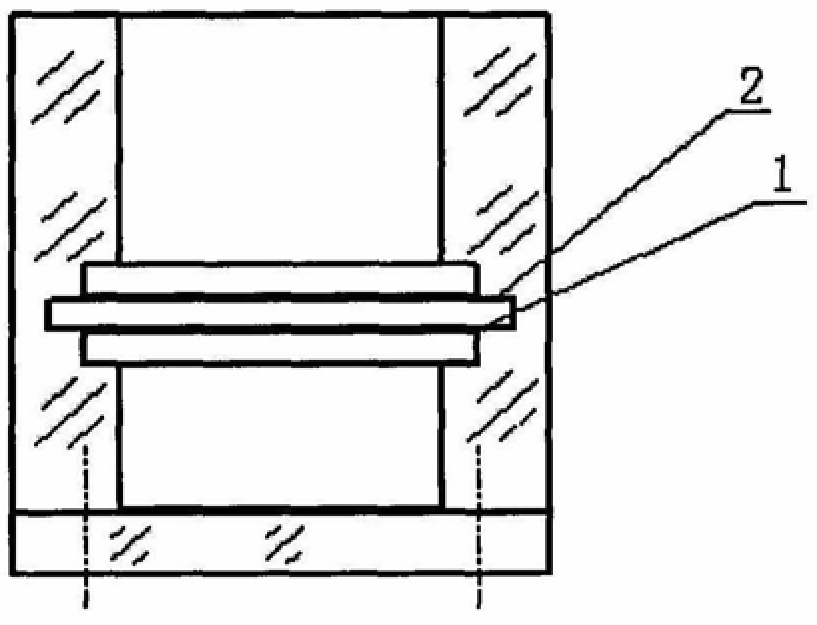

A limit calibration gauge and limit calibration method for a special measuring tool for nuclear fuel elements Technical field The invention belongs to the technical field of geometric quantity on-line calibration method, be specifically related to a kind of special measuring tool for nuclear fuel element Limit calibration gauge and limit calibration method. Background technique [0002] The special measuring tool for nuclear fuel elements is mainly used for the technical indicators of fuel rods, parts, bundles and assemblies of nuclear fuel elements. Special measuring instruments for testing, specifically used for measuring the length, dimension and shape and position errors of components such as fuel rods and bundles. Detect and determine whether the requirements are met, and give the test results at the same time. The accuracy of the special measuring tool is important for the quality of nuclear fuel elements Guarantee, the special measuring tool for nuclear fuel elem...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G01L25/00G21C17/06

CPCY02E30/30

Inventor 云鹏俊李婷婷赵宏李洪刚李阳马秀峰

Owner CHINA NUCLEAR BAOTOU GUANGHUA CHEM IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com