Universal Double Cover Hot Cell Service Airlock

A double-cover and airlock technology, which is applied in protected small rooms and nuclear engineering, can solve the problems of poor strength, poor sealing safety of air tents, and easy damage, and achieve the effect of high strength and good sealing performance

Inactive Publication Date: 2015-09-02

CHINA NUCLEAR POWER ENG CO LTD

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The sealing boundary is a plastic film, which has poor strength and is easy to be damaged, resulting in poor sealing safety of the air tent

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

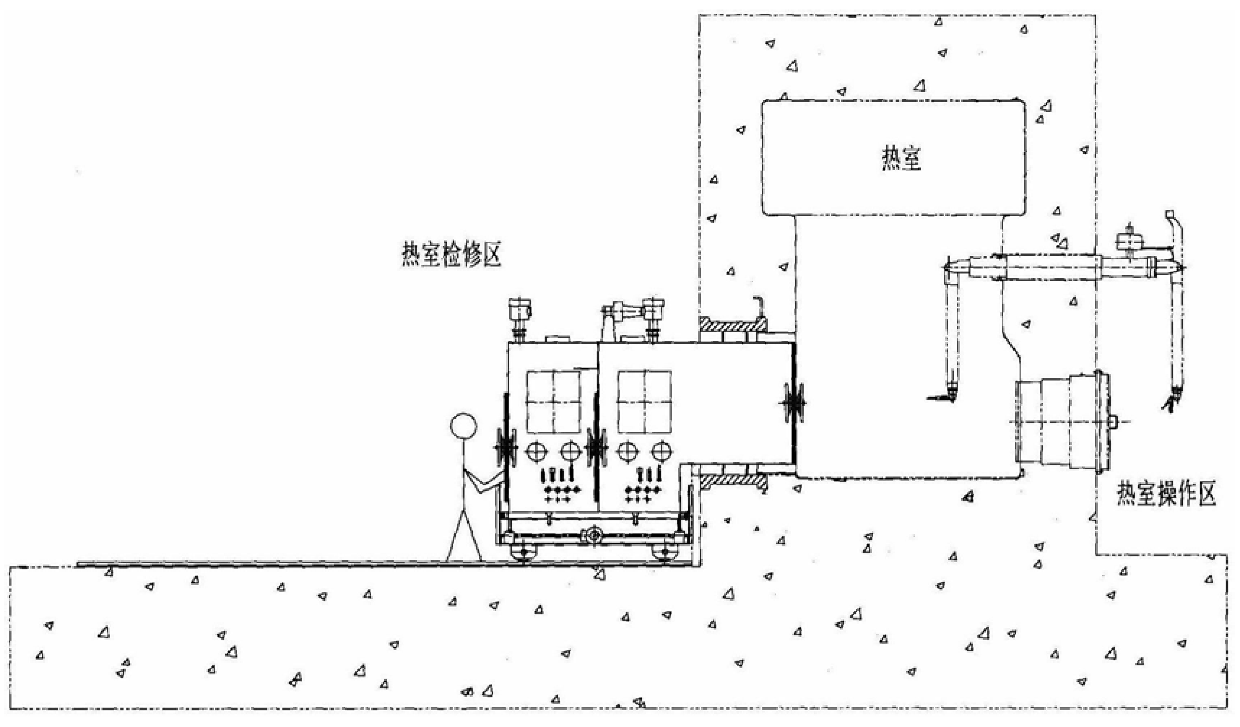

[0044] As shown in Figure 4: promote (manpower or electric) dolly along the track to dock the airlock with the heat chamber.

[0047] As shown in Figure 7: the airlock is withdrawn by the personnel, the hot cell inspection door is closed, and the maintenance task is completed.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

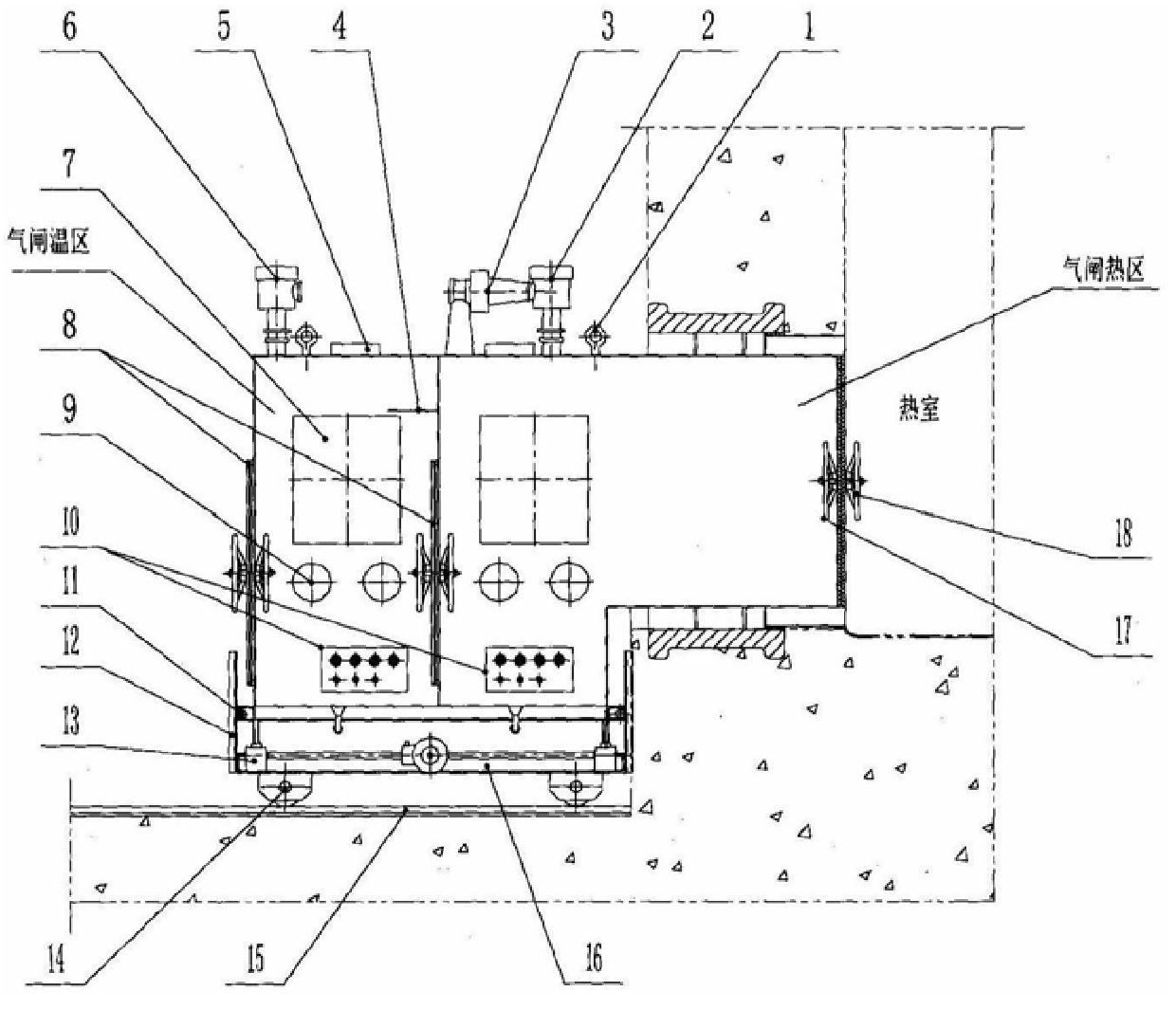

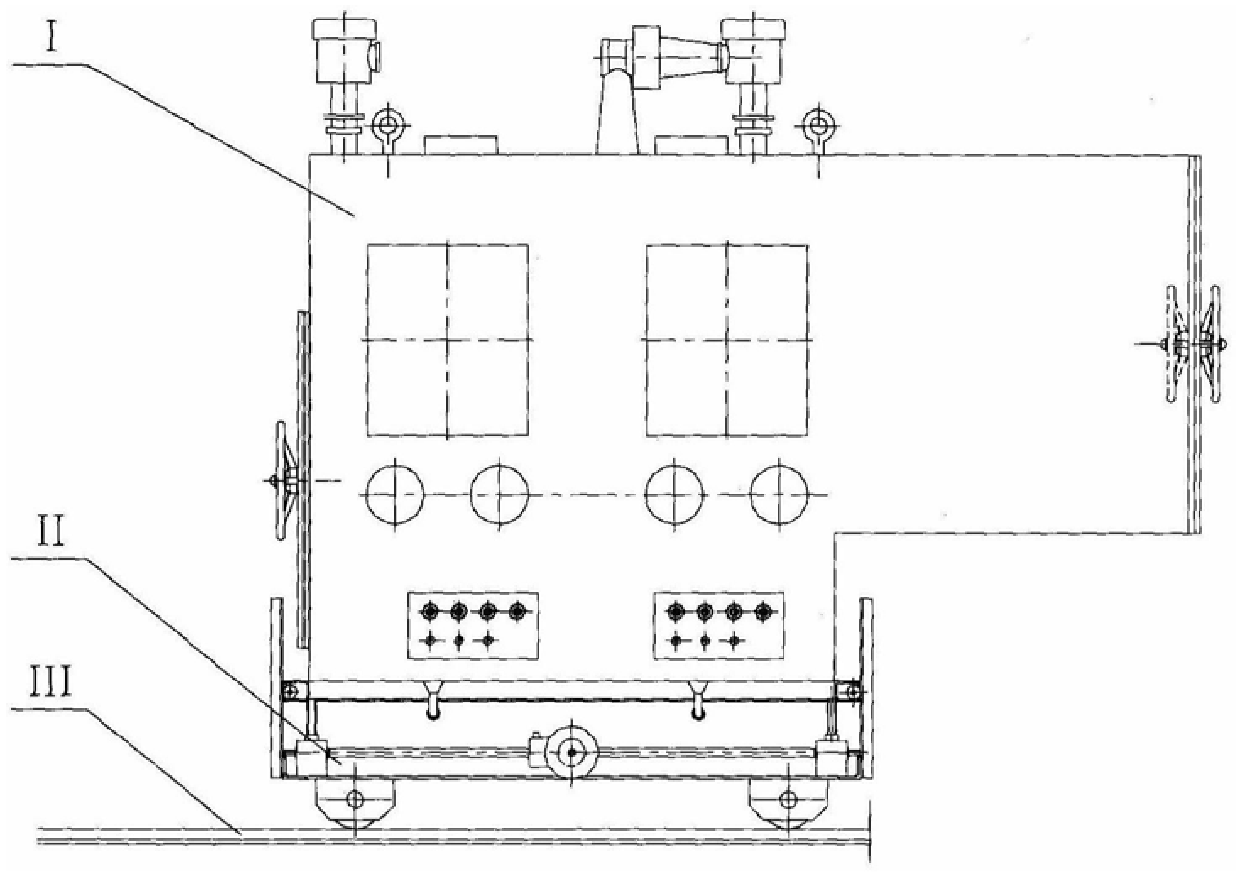

The invention belongs to the field of chamber design of the nuclear industry, and in particular relates to a general double-cover type hot cell maintenance airlock. The purpose is to provide a general-purpose double-cover type hot cell maintenance airlock that can be commonly used in different hot cells. The airlock body is a sealed chamber made of stainless acid-resistant steel plates. There are two independent partitions in the inner temperature zone and the hot zone. The independent zones are connected through a sealed door; the temperature zone is also equipped with a sealed door and a hot room outside the airlock for maintenance. The area is connected; the hot area is additionally provided with a sealed door to connect with the hot chamber; the hot area of the airlock body and the hot chamber are provided with a double-covered airtight door, and the double-covered airtight door is sealed by a double cover installed in the hot area of the airlock body. It consists of an outer door and a double-cover sealed inner door installed on the heat chamber shell. The advantages are high strength and good sealing performance; it eliminates the need to repeatedly build an air tent, realizes fast docking and disengagement, and the interface surface is not contaminated after separation, and it also has the advantages of convenient transfer.

Description

Universal Double Cover Hot Cell Maintenance Airlock Technical Field The invention belongs to the nuclear industry chamber design field, be specifically related to a kind of specialized equipment for personnel to enter hot chamber maintenance Repair the airlock (hereinafter referred to as: airlock) with chamber equipment - general double-covered hot chamber. Background technique Along with the development of my country's nuclear industry, in nuclear engineering, for the requirement of equipment maintenance, replacement, operation under the radioactive environment Higher and higher. Especially in recent years, with the continuous improvement of people's awareness of environmental protection, people-oriented design requirements are more used Advocated by users, it is required to avoid personnel entering the contaminated area for maintenance operations as much as possible. As much as possible, remote operation and maintenance methods are used in the equipment design, and ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G21F7/00

Inventor 胡国辉曾敏学许源振降宇波

Owner CHINA NUCLEAR POWER ENG CO LTD

Features

- Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com