Non-woven table mat and making method thereof

A production method and technology of placemats, which are applied to tableware, household appliances, applications, etc., can solve the problems of low structural strength, poor economy, easy damage, etc., achieve large market competitiveness, ensure waterproof performance, and improve structural strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

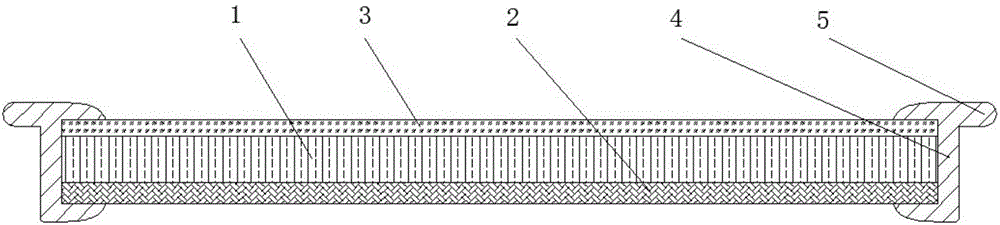

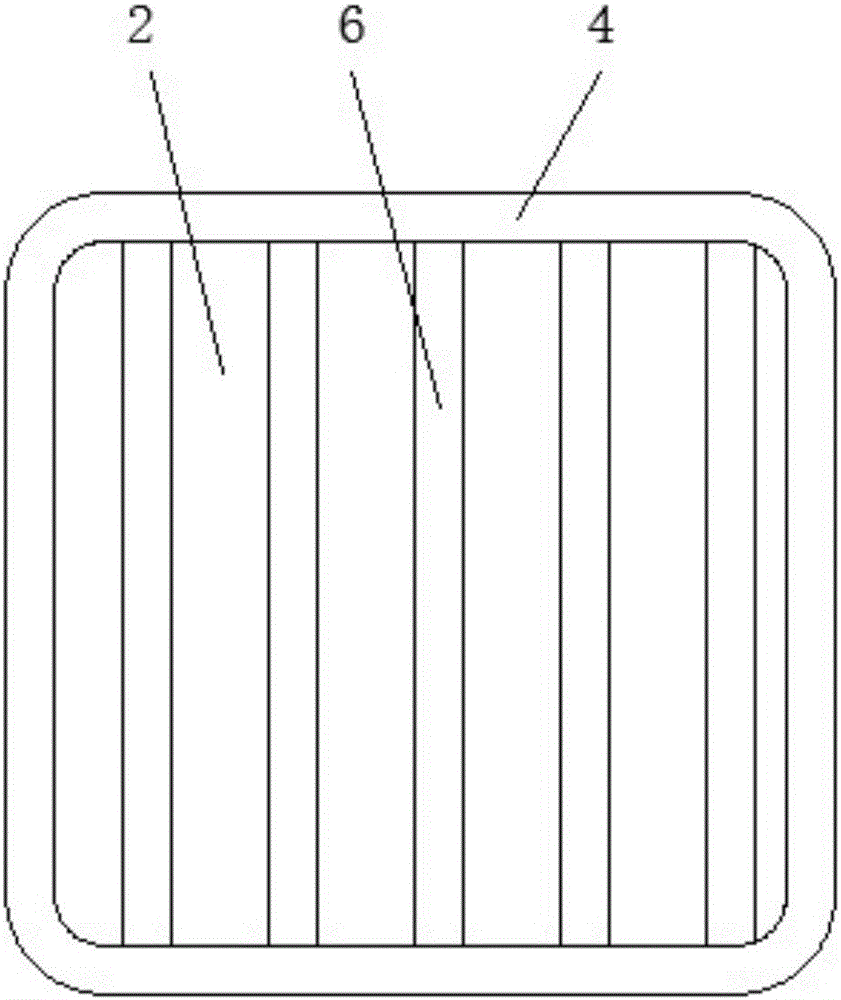

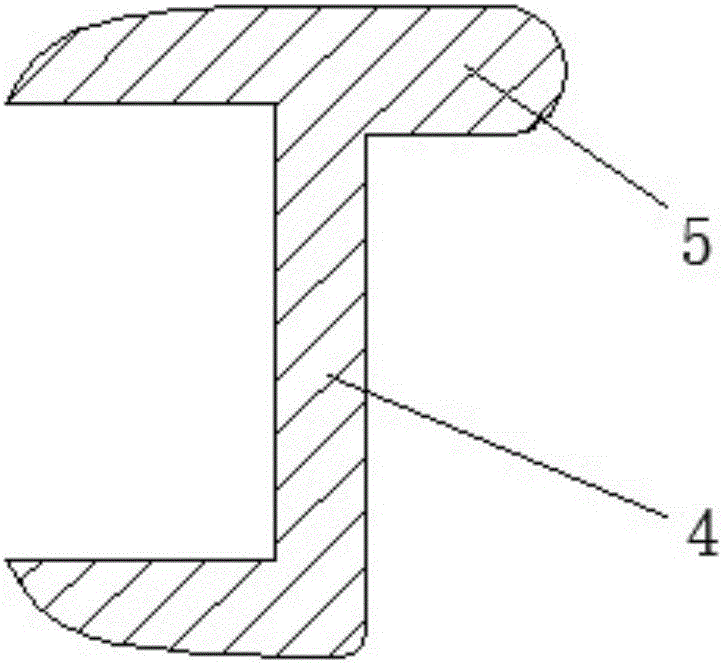

[0029] A kind of non-woven placemat of the present invention, as figure 1 , image 3 As shown, it includes: a non-woven base layer 1 made of polyester fiber through needle punching and a film layer 2 formed by laminating polyethylene material; the upper surface of the film layer 2 and the non-woven base layer 1 The lower surface of the non-woven base layer 1 is connected to the upper surface of the transfer printing layer 3; the transfer printing layer 3, the non-woven base layer 1 and the coating layer 2 are connected as an integral structure, and the whole is surrounded by a package Integral seam tape 4; the upper peripheral side of the seam tape 4 is provided with a pull edge 5; the pull edge 5 and the seam tape 4 are integrally formed.

[0030] Preferably, a non-woven placemat according to the present invention is characterized in that: the overlock tape 4 and the pull edge 5 are made of soft materials, preferably silica gel materials; wherein, the The overlock width of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com