Turbulent flow and chemical agglomeration coupling fine particle agglomeration device

A technology of chemical agglomeration and fine particles, applied in chemical instruments and methods, separation of dispersed particles, separation of electrostatic effects, etc., can solve the problems of changing the surface of particles and increasing the effective collision between particles, so as to achieve simple equipment, increase adhesion, The effect of low investment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

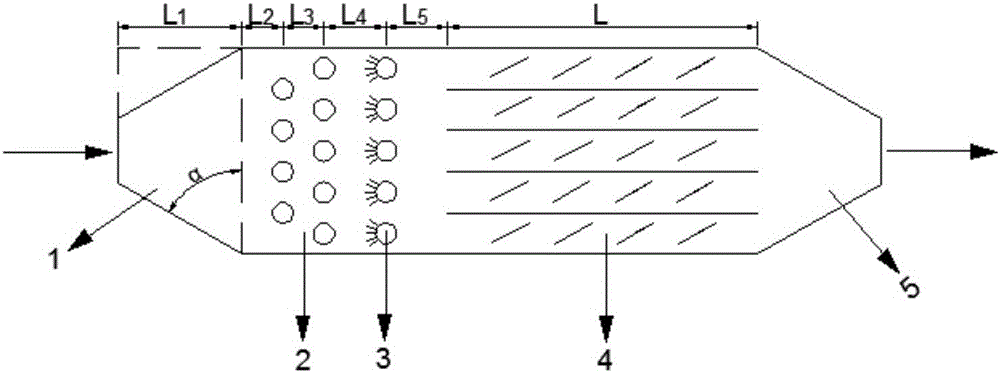

[0016] .combined with figure 1 The flow and chemical agglomeration coupled fine particle agglomeration device of the present invention is described. The agglomeration device includes a flue gas inlet enlargement section 1, a turbulent flow initial section 2, an atomization section 3, a vortex turbulence section 4, and an outlet narrowing section 5. The agglomeration device is a three-dimensional vertical equipment with a section of 250×450mm and a length of 2470mm. The lengths of the flue gas inlet enlarged section 1 and the outlet narrowed section 5 are respectively 235 mm (L1 = 235 mm), and the angle α between the inlet or outlet and the flue gas flow direction is 60°. The length of the turbulent flow section 4 of the vortex slices is 1300mm (L=1300mm), and it is divided into 5 micro-sections with a steel plate with a thickness of 1.5mm, equipped with 4 sets of vortex slices, the distance between each set of vortex slices is 260mm, and each set of vortex slices contains 4 T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com