Raw gemstone machining method

A processing method and rough stone technology, applied in stone processing equipment, stone processing tools, metal processing equipment, etc., can solve the problems of incomplete removal of the leather shell and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

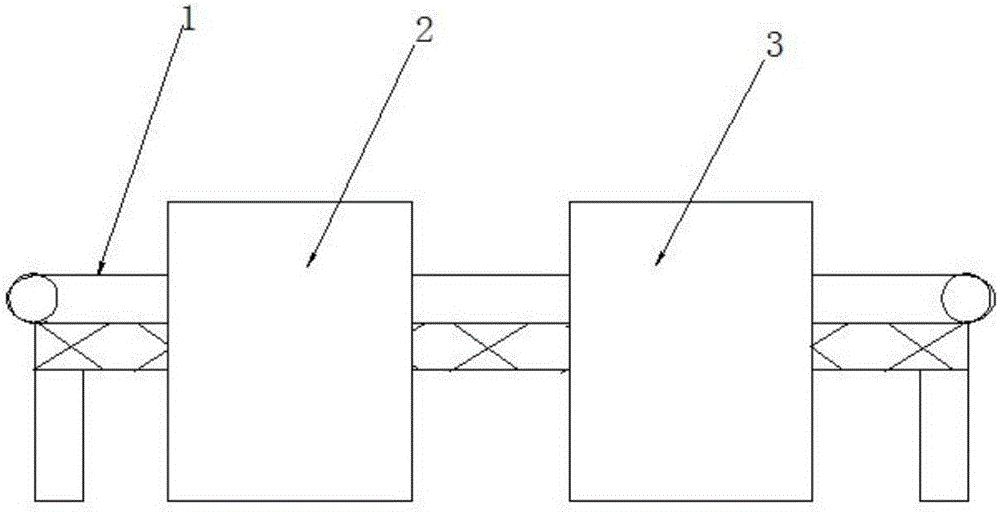

[0045] Such as figure 1 As shown, a rough stone grinding line, including:

[0046] Conveyor belt 1 for conveying rough stones in the assembly line;

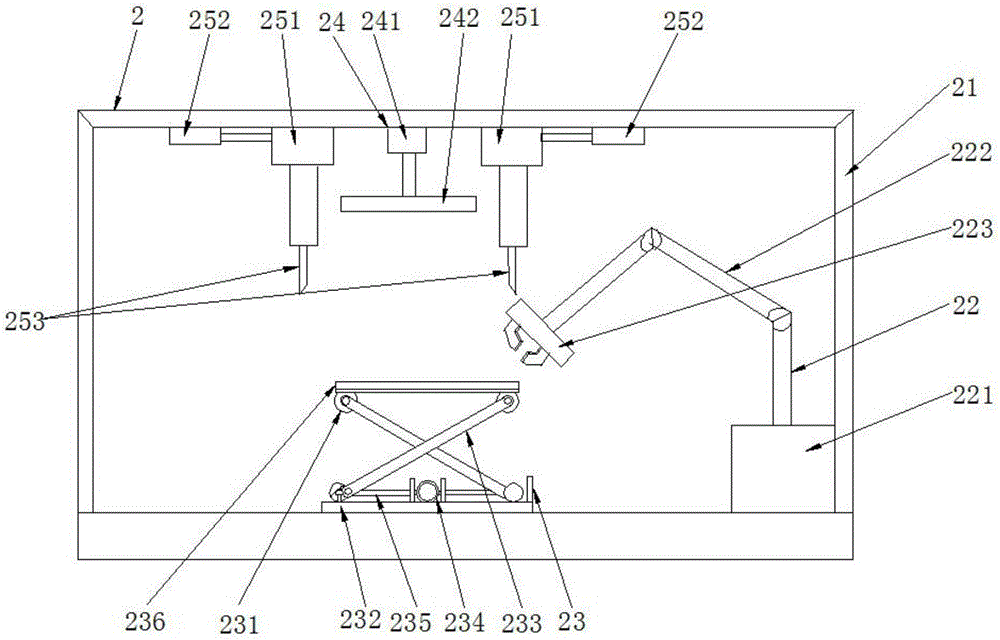

[0047] The rough stone cutting device 2 is arranged on the side of the conveyor belt 1, and is used for grabbing the rough stone and cutting the rough stone;

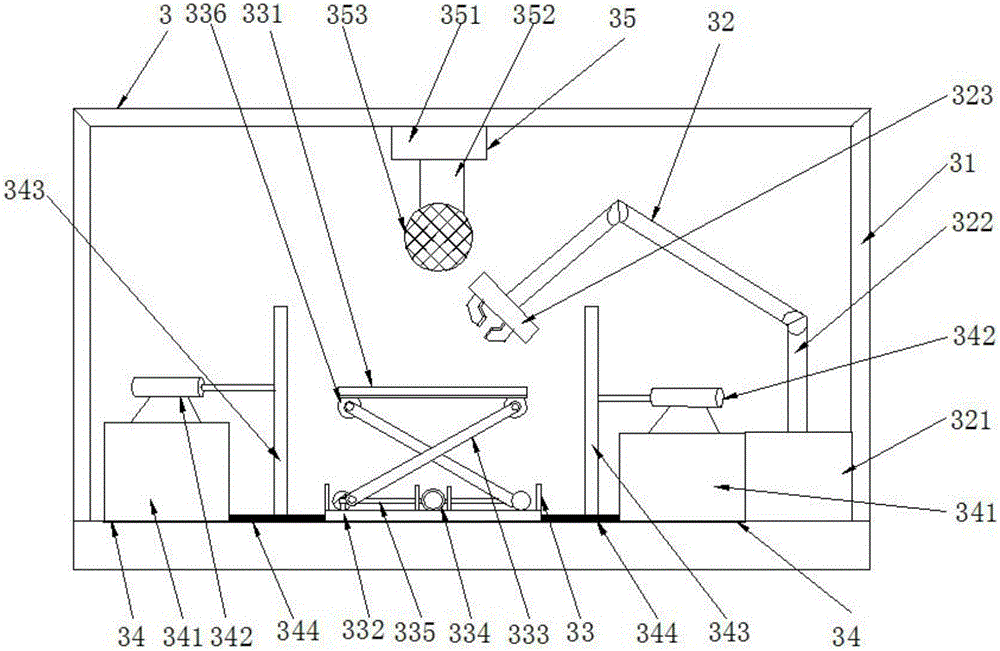

[0048] The rough stone grinding device 3 is arranged on the side of the conveyor belt 1, and is used for performing secondary grinding treatment on the cut rough stone.

[0049] Specifically, in the rough stone polishing line, the conveyor belt 1 drives the rotation of the rough stone, and on both sides of the conveyor belt, the rough stone cutting device 2 and the rough stone polishing device 3 are arranged in sequence, that is, the rough stone passes through the rough stone cutting device 2 and the rough stone in turn. Grinding device 3. When the rough stone passes through the rough stone cutting device 2, the rough stone cutting device 2 grabs the rough stone and pla...

Embodiment 2

[0084] According to the rough stone grinding line proposed in the above embodiments, this embodiment proposes a rough stone processing method, which is suitable for the above rough stone grinding line.

[0085] Such as Figure 4 Shown, a kind of raw stone processing method comprises steps:

[0086] S1. After the first grabbing mechanism 22 grabs the rough stone from the conveyor belt 1, place it on the first lifting platform 23;

[0087] S2. Provide an infrared distance measuring device fixedly installed on the first support frame 21, measure the height of the rough stone, and adjust the height of the first lifting platform 23 according to the height of the rough stone;

[0088] S3. The first cylinder 241 drives the fixed plate 242 to move downward, and the fixed plate 242 abuts against the top of the original stone, and fixes the original stone between the fixed plate 242 and the first bearing plate 231 of the first lifting platform 23;

[0089] S4. Provide a number of imag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com