Adjustable tire unloading device for tire vulcanizing machine

A tire vulcanization and adjustable technology, applied in tires, household appliances, other household appliances, etc., can solve the problems of the tire unloading arm stuck, easy to bend, easy to damage the copper sleeve, etc., to achieve the effect of not easy to deform and ingenious design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solutions of the present invention will be further described below in conjunction with the embodiments shown in the accompanying drawings.

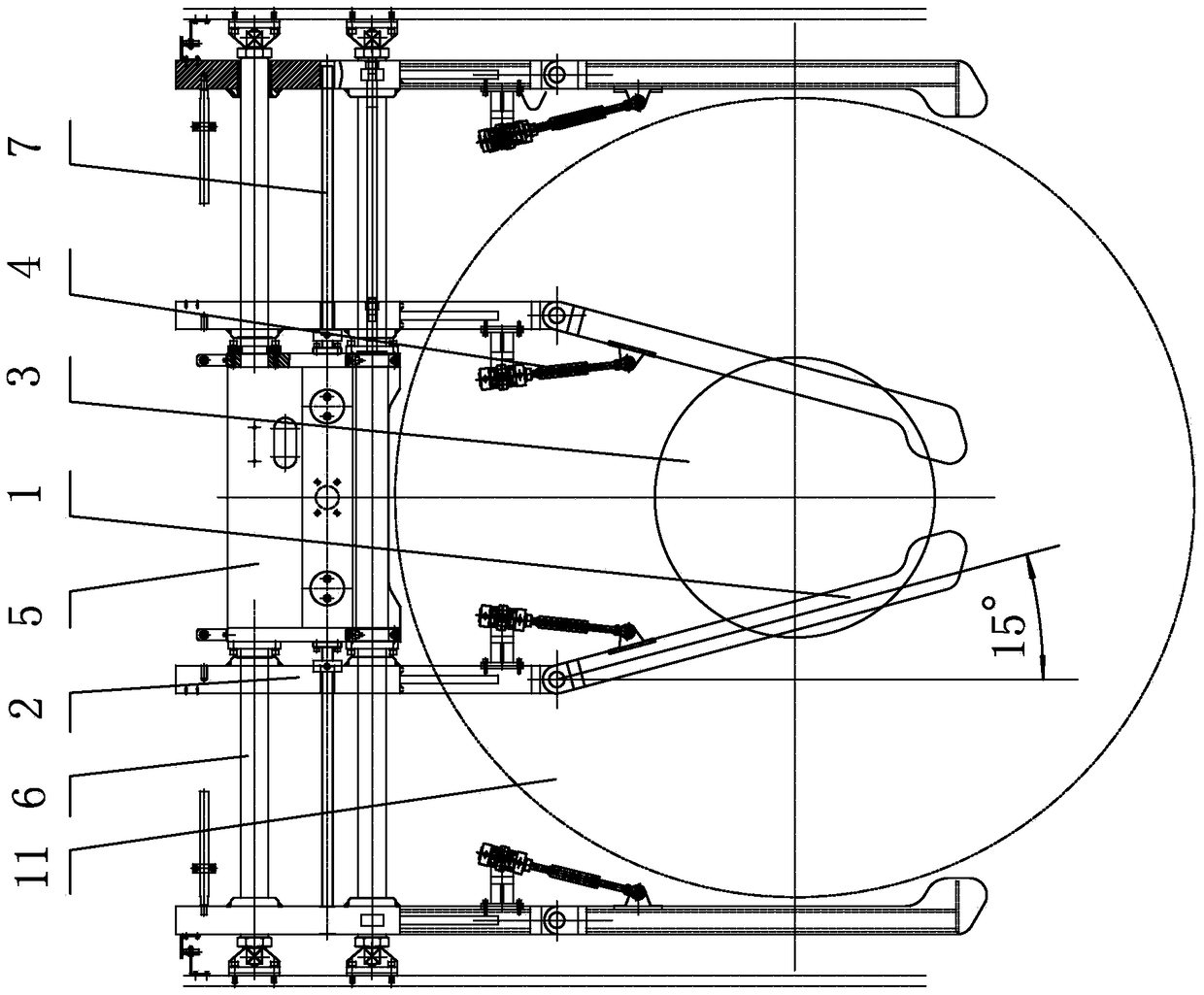

[0020] The adjustable tire unloading device of the tire vulcanizer of the present invention includes left and right tire unloading arms, and the left and right unloading arms make closing motions relative to the vulcanizing machine steamer 11 under the action of the control mechanism, and open motions opposite to each other until vulcanization Outside the machine steamer 11, the control mechanism is located at the rear of the vulcanizer steamer 11, such as figure 1 shown.

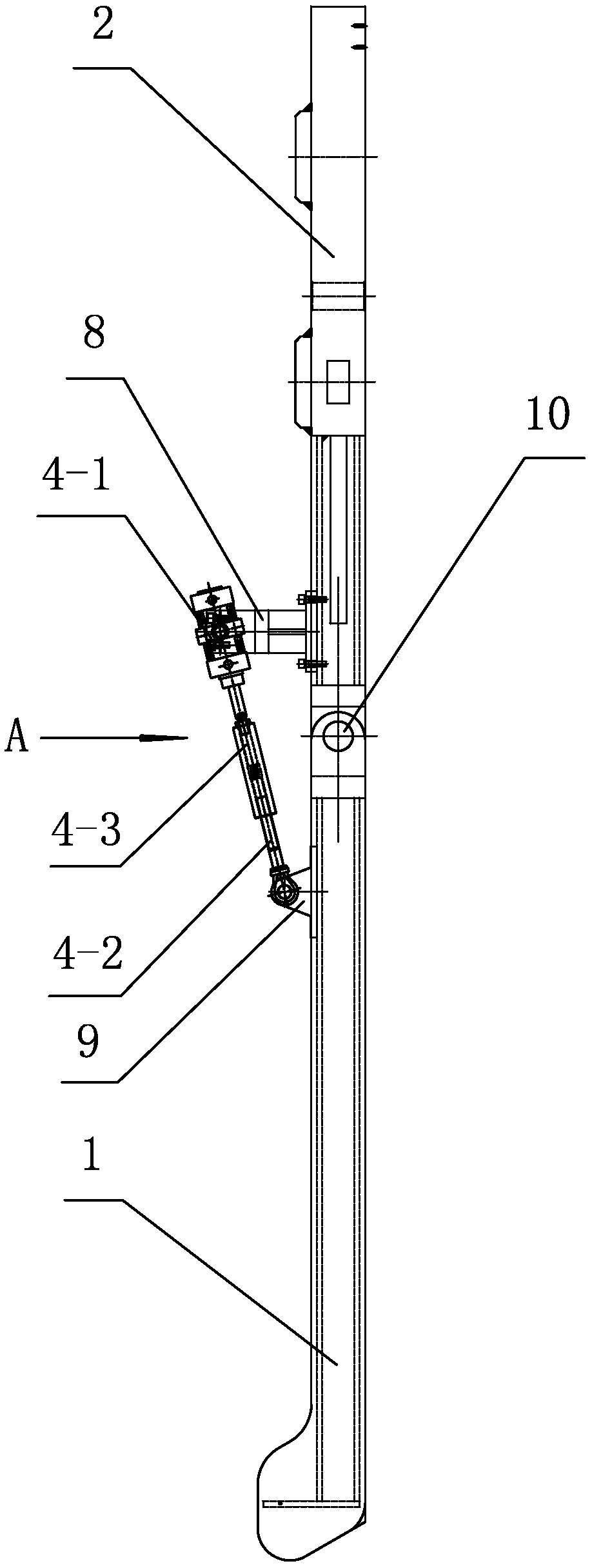

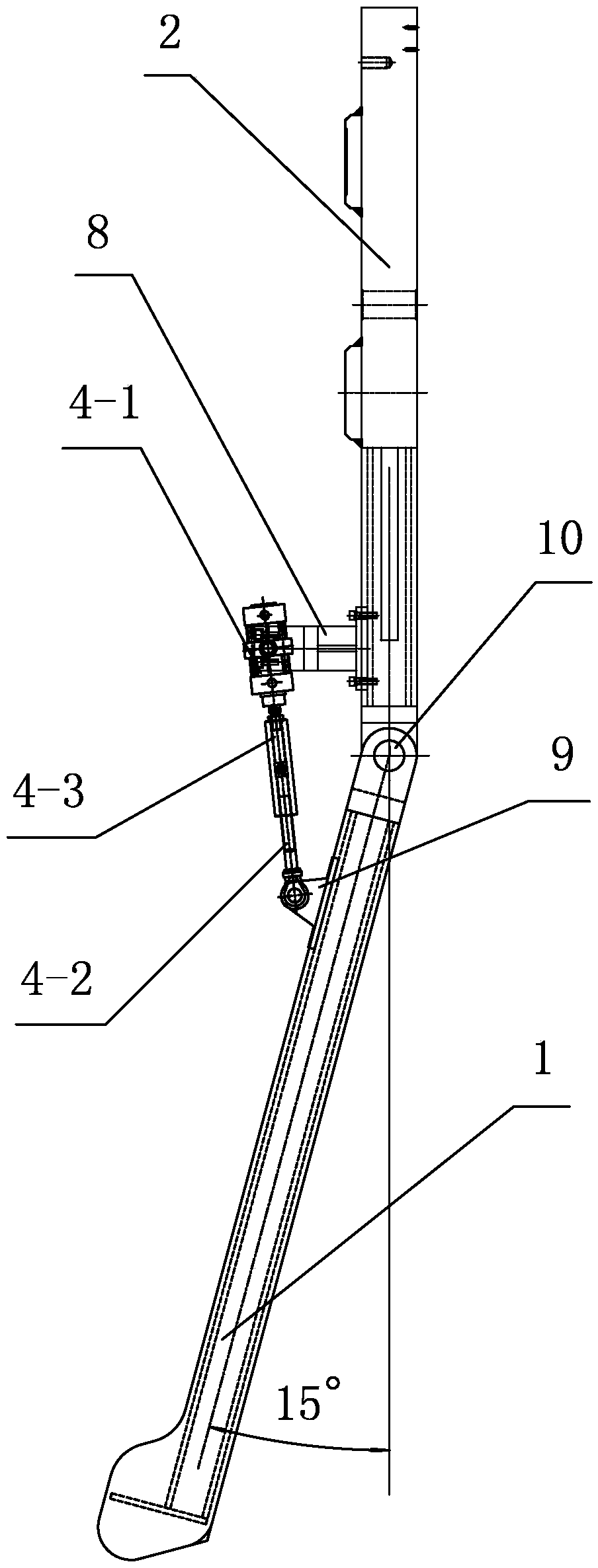

[0021] The tire unloading arm includes a forearm 1 and a rear arm 2, the rear end of the forearm 1 is hinged with the front end of the rear arm 2 through a vertical pivot pin 10, and the inner side of the forearm 1 and the rear arm 2 is provided with a front arm that pushes the forearm 1 to the inside. The deflection angle adjustment mechanism, ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com