Firm silk film and processing method thereof

A processing method and silk technology, which are applied in the field of objects or materials for storage or transportation, can solve the problems that the safety and stability of film preservation cannot be guaranteed, the film cannot be used for dredging, and the packaging does not meet the requirements, and the decoration effect can be improved. , Strengthening strength, soft touch effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

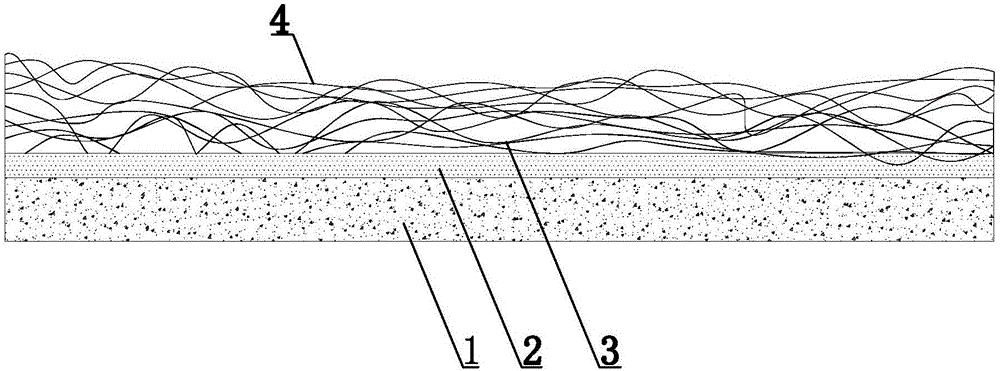

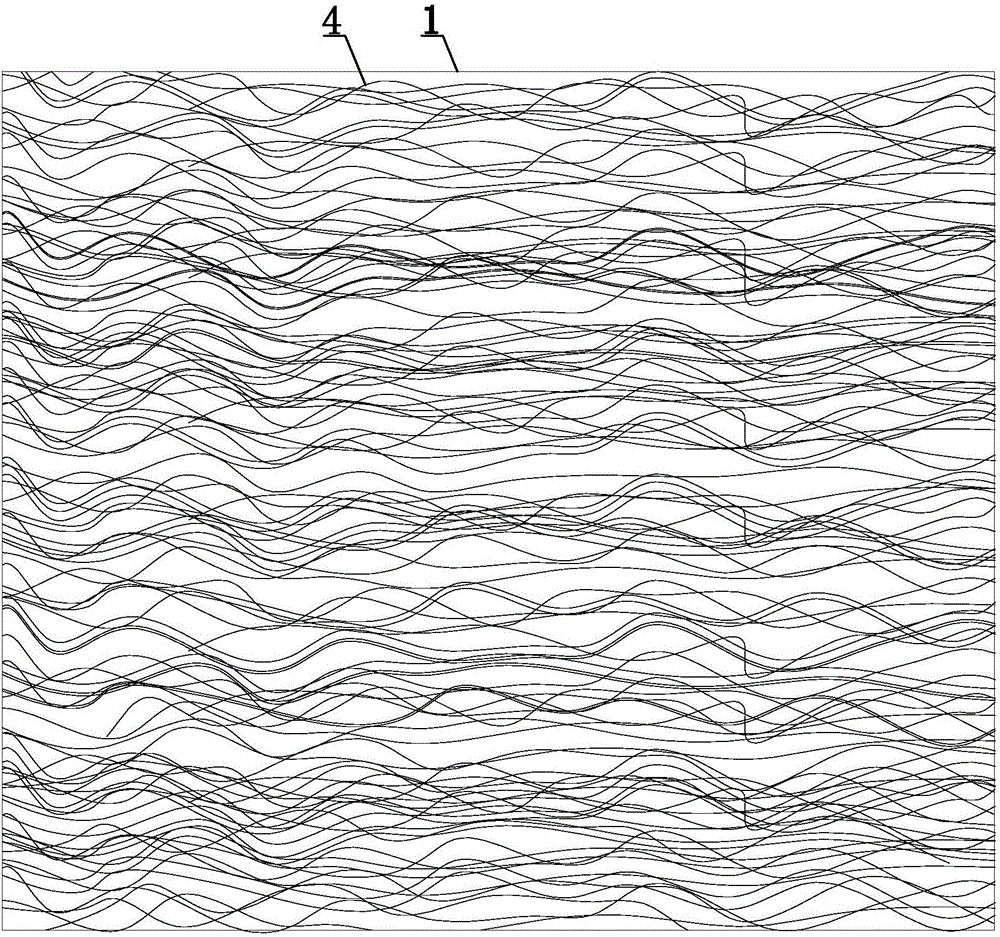

[0023] The firm type silk film of this embodiment combines figure 1 and figure 2 , from bottom to top are the hard substrate 1, the bottom film 2, the fiber layer 3 and the silk layer 4, the bottom film 2 is bonded on the hard substrate 1, and the fiber layer 3 and the silk layer 4 are sequentially arranged on the bottom film 2, and The bottom of the fibrous layer 3 extends into the base film 2, and the joints of the fibrous layer 3 and the silk layer 4 intersect each other, forming an incoherent fuzzy boundary. In this embodiment, the fiber layer 3 is made of PET fibers, and the PET fibers extend into the bottom film 2, so that the bottom of the fiber layer 3 extends into the bottom film 2; the fiber layer 3 is bonded to the bottom film 2 by an auxiliary agent, and the corresponding , the silk layer 4 is bonded on the fiber layer 3 by an auxiliary agent.

[0024] The processing method of above-mentioned film comprises two steps:

[0025] (1) Forming of fiber layer and sil...

Embodiment 2

[0028] The firm type silk film of this embodiment combines figure 1 and figure 2 , from bottom to top are the hard substrate 1, the bottom film 2, the fiber layer 3 and the silk layer 4, the bottom film 2 is bonded on the hard substrate 1, and the fiber layer 3 and the silk layer 4 are sequentially arranged on the bottom film 2, and The bottom of the fibrous layer 3 extends into the base film 2, and the joints of the fibrous layer 3 and the silk layer 4 intersect each other, forming an incoherent fuzzy boundary. In this embodiment, the fiber layer 3 is made of PET fibers, and the PET fibers extend into the bottom film 2, so that the bottom of the fiber layer 3 extends into the bottom film 2; the fiber layer 3 is bonded to the bottom film 2 by an auxiliary agent, and the corresponding , the silk layer 4 is bonded on the fiber layer 3 by an auxiliary agent.

[0029] The processing method of the above-mentioned film includes two steps: (1) Forming of fiber layer and silk layer...

Embodiment 3

[0031] The firm type silk film of this embodiment combines figure 1 and figure 2 , from bottom to top are the hard substrate 1, the bottom film 2, the fiber layer 3 and the silk layer 4, the bottom film 2 is bonded on the hard substrate 1, and the fiber layer 3 and the silk layer 4 are sequentially arranged on the bottom film 2, and The bottom of the fibrous layer 3 extends into the base film 2, and the joints of the fibrous layer 3 and the silk layer 4 intersect each other, forming an incoherent fuzzy boundary. In this embodiment, the fiber layer 3 is made of PET fibers, and the PET fibers extend into the bottom film 2, so that the bottom of the fiber layer 3 extends into the bottom film 2; the fiber layer 3 is bonded to the bottom film 2 by an auxiliary agent, and the corresponding , the silk layer 4 is bonded on the fiber layer 3 by an auxiliary agent.

[0032] The processing method of the above-mentioned film includes three steps: (1) Forming of fiber layer and silk lay...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com