Air conditioner unit platform of urban rail vehicle

A technology for air-conditioning units and urban rail vehicles, which is applied in the heating/cooling of railway vehicles, railway car body parts, transportation and packaging, etc., and can solve problems such as inability to meet the needs of rainwater drainage, high flatness requirements, and large weld lengths , to achieve the effect of reducing manual welding, improving platform flatness and sealing performance, and good sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with accompanying drawing.

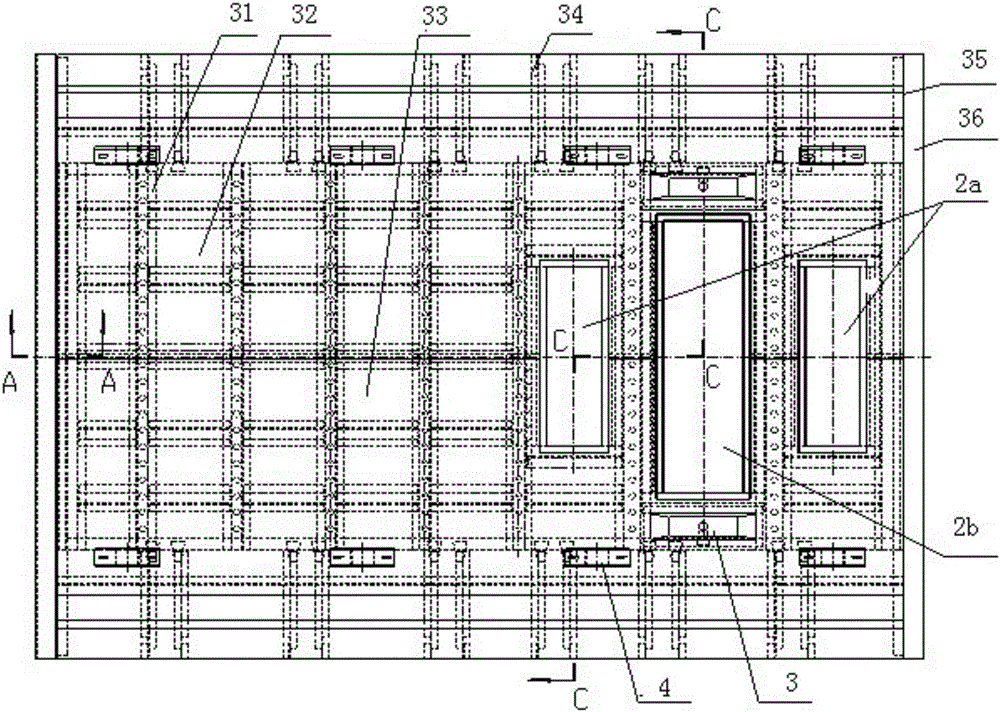

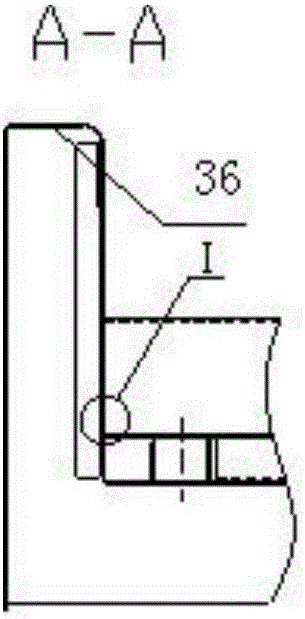

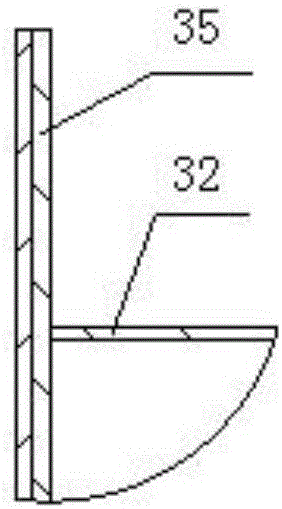

[0032] Such as Figure 5-Figure 13 As shown, on the platform of the air-conditioning unit of the urban rail vehicle, the frame 1 is welded with the sealing frame 2, the drainage groove 3 and the mounting seat 4, and the sealing frame 2 is provided with the air supply chamber 2a and the return air chamber 2b, and the air supply chamber 2a and the return air chamber 2b is arranged parallel to the vehicle width direction. According to the continuity requirements of the air supply duct of the vehicle air duct system along the vehicle length direction, determine the arrangement of the air supply outlets and return air outlets along the vehicle width direction.

[0033] The skeleton 1 is cross-welded by the skeleton longitudinal beam 11 and the skeleton cross beam 12, the longitudinal beam 13 is welded at the upper and lower ends, the skin support beam 14 is welded at the left a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com