Automobile cargo carrying center of gravity adjusting mechanism

A technology for adjusting the center of gravity and adjusting the motor, which is applied to the upper structure, upper structure, vehicle parts, etc. of the truck, which can solve the problems of vehicle rollover and cargo falling, and achieves the goal of not easy to rollover, stable vehicle and cargo, Guaranteed safe effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

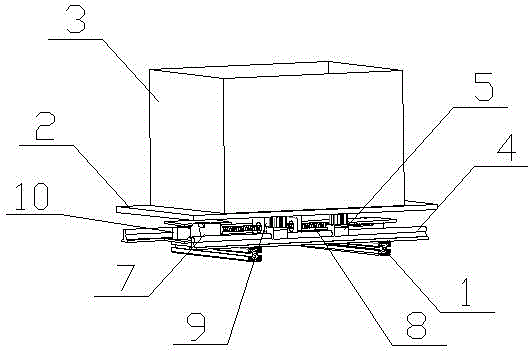

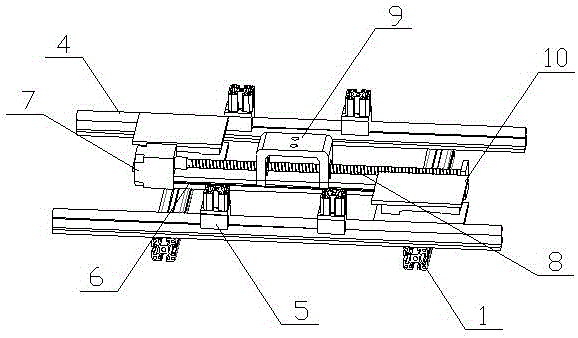

[0029] Example: see figure 1 , figure 2 , a vehicle load center of gravity adjustment mechanism, including a bottom support bar 1, a pallet 2 and a cargo box 3. The bottom support rods 1 are two and parallel to each other, two slide rails 4 are arranged above the bottom support rod 1, the length direction of the slide rails 4 is perpendicular to the length direction of the bottom support rod 1, and the two slide rails 4 are respectively Close to both ends of the bottom support rod 1. The supporting plate 2 is located above the bottom support rod 1, and on the lower side of the supporting plate 2, several slide blocks 5 are respectively arranged at the positions corresponding to the two slide rails 4, and the slide blocks 5 are slidably connected with the slide rails 4; Said container 3 is installed in the middle part of pallet 2, and is fixedly connected with pallet 2.

[0030] An adjustment mechanism is provided between the supporting plate 2 and the bottom support rod 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com