Part tray lifting mechanism

A technology of pallet lifting and parts, applied in conveyors, conveyor objects, transportation and packaging, etc., can solve problems such as low efficiency, affecting production rhythm, and poor safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

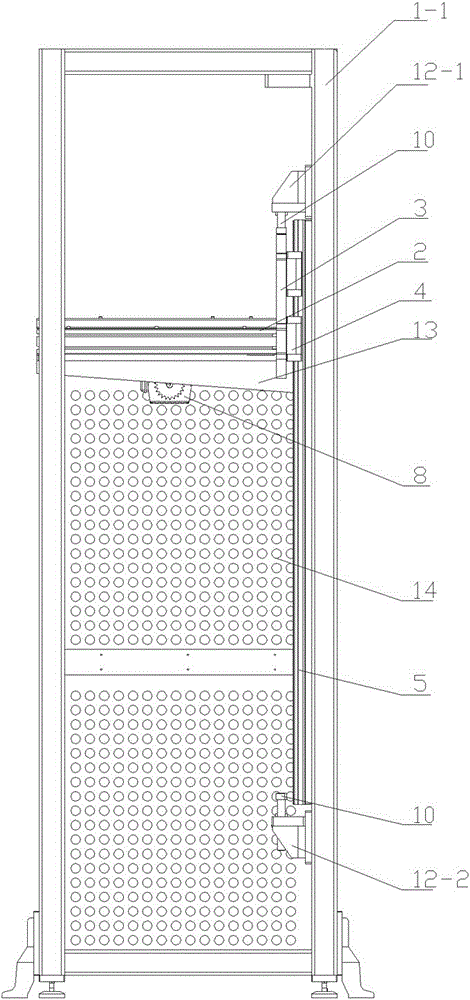

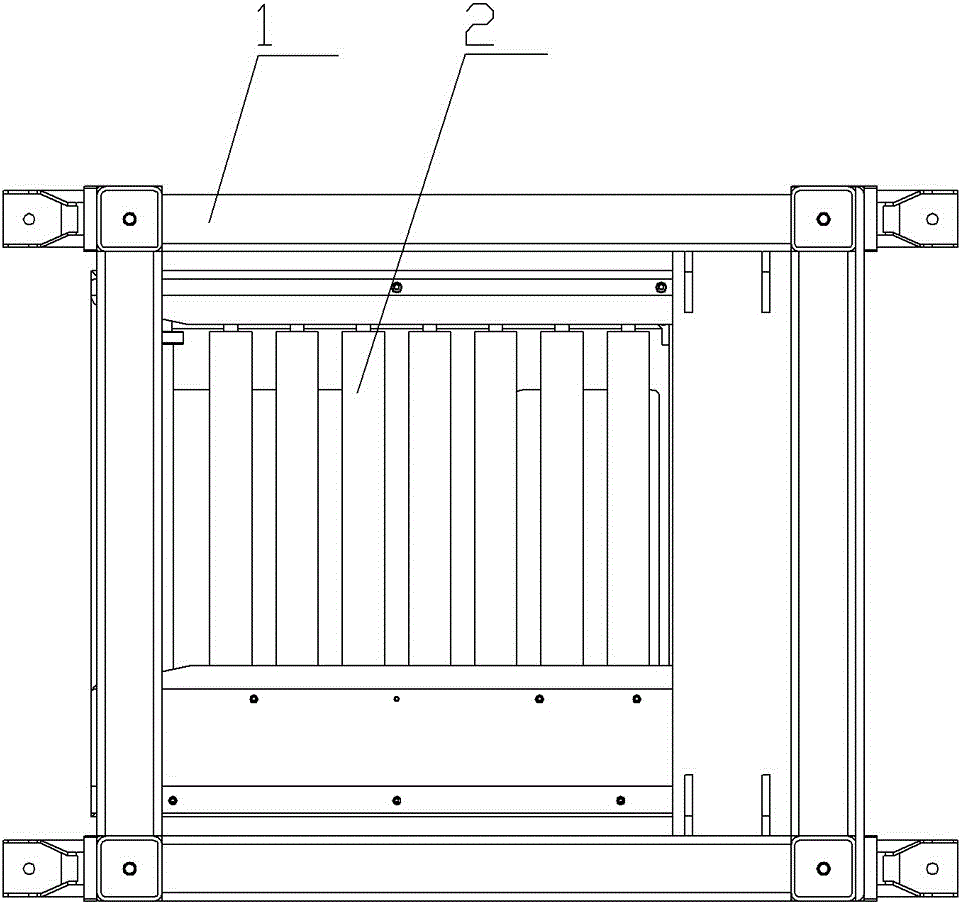

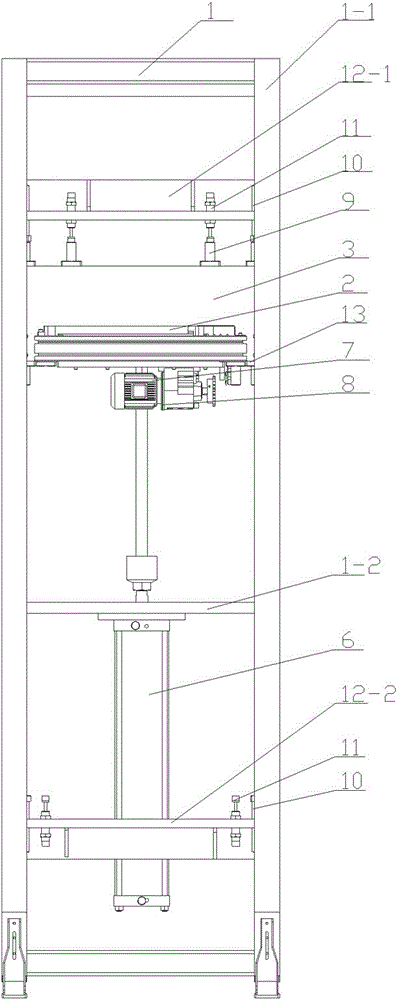

[0020] figure 1 , figure 2 , image 3 , Figure 4 Middle: frame 1, support frame 1-1, support plate 1-2; roller conveying seat 2, roller 2-1, inclined guide plate 2-2; lifting seat 3; guide rail 4; slider 5; cylinder 6; transmission Motor 7, mounting frame 8; sleeve 9; limit post 10, buffer limit post 11; upper limit mounting plate 12-1, lower limit mounting plate 12-2; fixed plate 13; protective plate 14.

[0021] see Figure 1-Figure 4 As shown, a parts pallet lifting mechanism includes a frame 1, a roller conveying seat 2, on which a roller 2-1 is arranged, and a plurality of parallel rollers 2-1 arranged side by side pass through a sprocket (in the figure) Not expressed) connected together so that the rollers on the roller conveying seat 2 can rotate synchronously, the sprocket is connected to the transmission motor 7, and the two ends of the roller 2-1 on the roller conveying seat 2 are respectively provided with inclined guide plates 2 -2. The parts tray channel is formed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com