Transformer station suspension bracket pedestal and spare transformer station suspension bracket

A technology for substations and hangers, applied to cranes and other directions, can solve the problems of out of reach, lifting height, long time, and long construction period, and achieve the effect of stable support and convenient movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

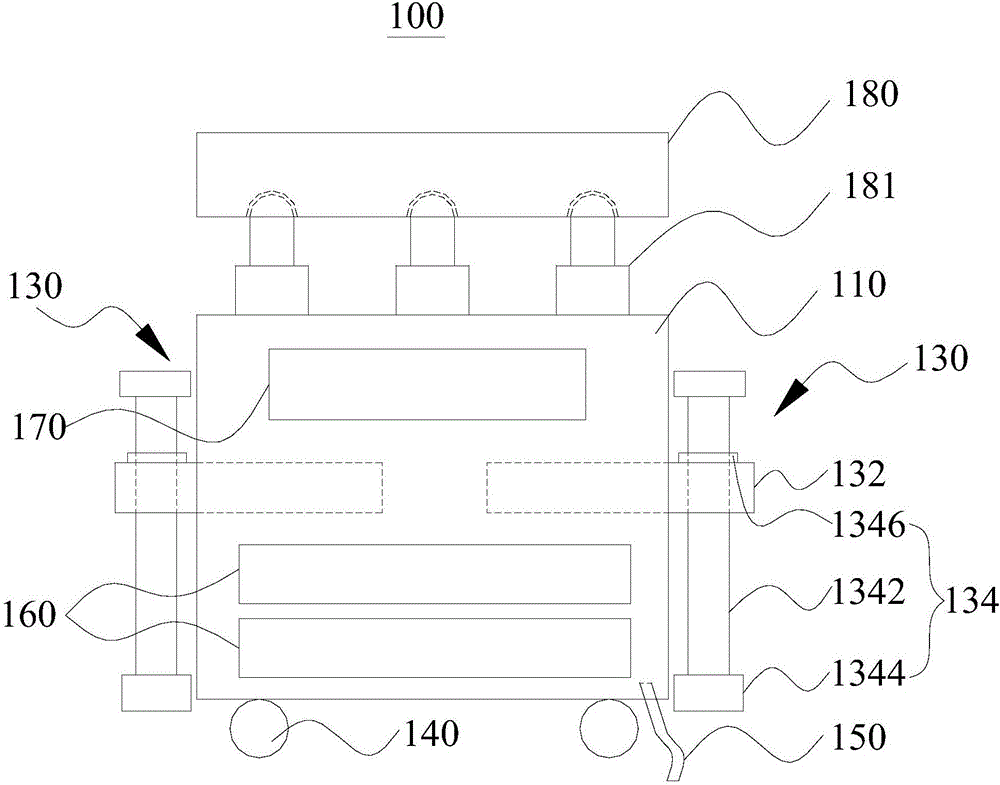

[0036] Please refer to figure 1 , the present embodiment provides a substation hanger base 100 , which includes a base body 110 , a support base 130 , a traveling wheel 140 , a ground wire 150 , a counterweight 160 , a toolbox 170 and an adjustment platform 180 .

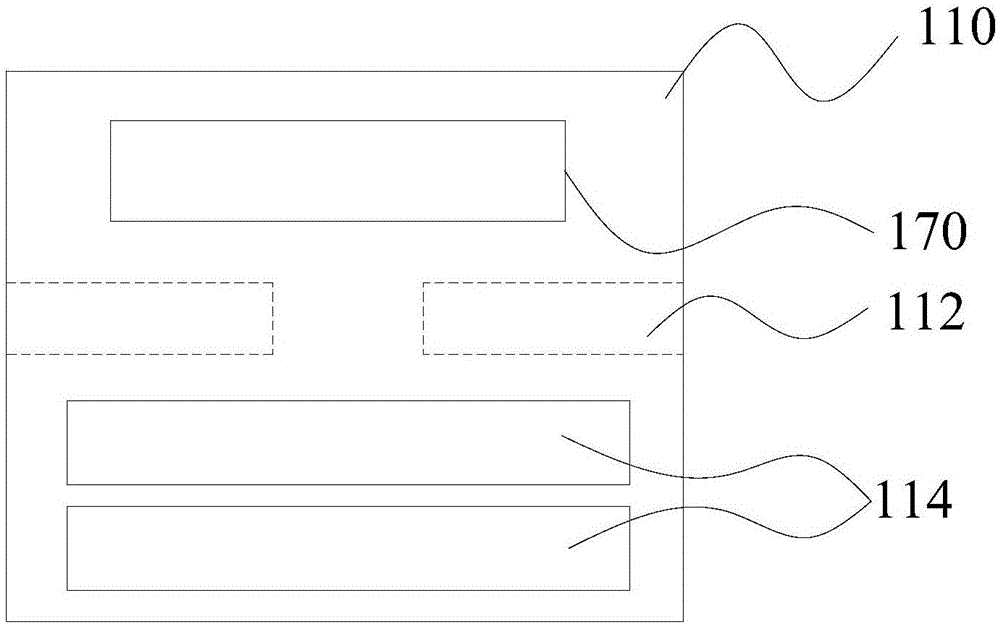

[0037] refer to figure 2, The seat body 110 is a cube made of metal material. The seat body 110 has a receiving cavity 112 . Further, the four sides of the base body 110 are provided with rectangular holes extending horizontally to the inside of the base body 110 , and the inner walls of the rectangular holes jointly define the receiving cavity 112 .

[0038] A counterweight cavity 114 for accommodating a counterweight 160 is also defined on the base body 110 . Further, a square hole extending horizontally toward the inside of the seat body 110 is opened on one side of the seat body 110 . The inner walls of the square hole collectively define a weight cavity 114 .

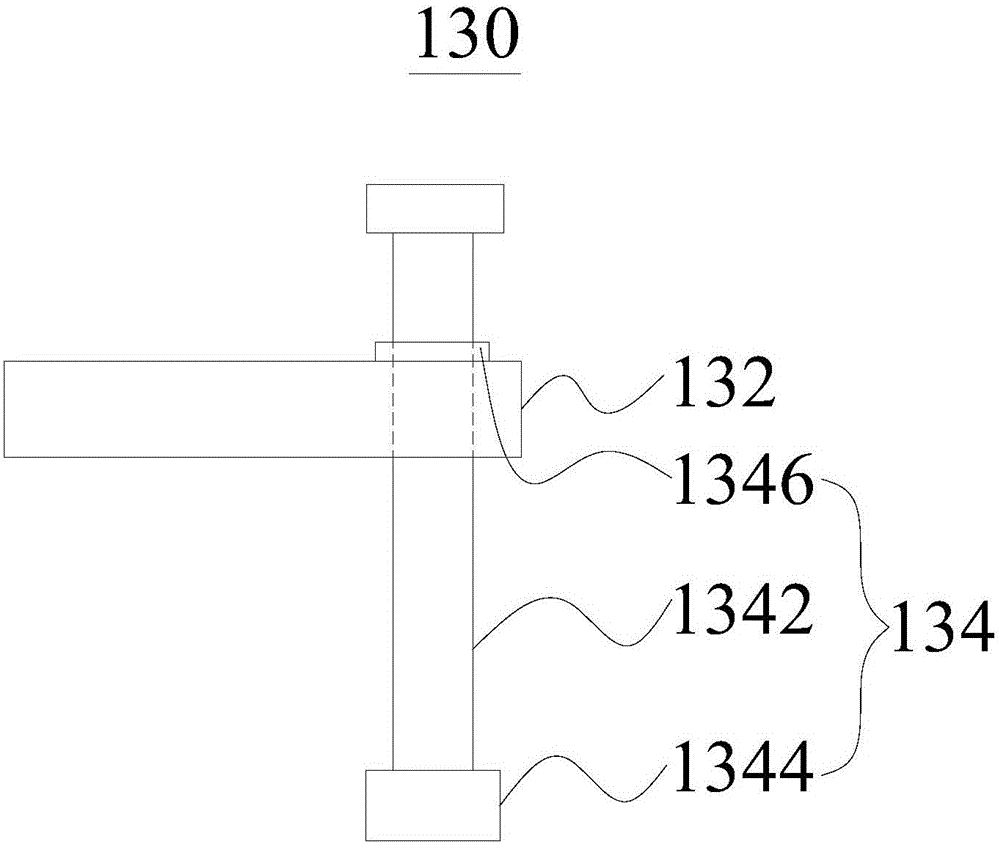

[0039] refer to figure 2 and image 3 , t...

Embodiment 2

[0059] Please refer to Figure 6 , this embodiment provides a substation standby hanger 200, which includes a column 210, a suspension arm 220, a hoisting mechanism 230, and the substation hanger base 100 in Embodiment 1.

[0060] The column 210 is a retractable structure. One end of the column 210 is connected to the suspension arm 220 , and the other end of the column 210 is connected to the top of the base body 110 of the substation hanger base 100 .

[0061] In this embodiment of the present invention, the column 210 includes a plurality of sub-columns, and the sub-columns are screwed to each other. Further, in this embodiment, the column 210 includes three sub-columns, namely a first sub-column 2111 , a second sub-column 2112 and a third sub-column 2113 .

[0062] The three sub-columns are in the shape of a cylinder, and the three sub-columns are nested and matched with each other, and two adjacent sub-columns are screwed. The connection situation shown here is that th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com