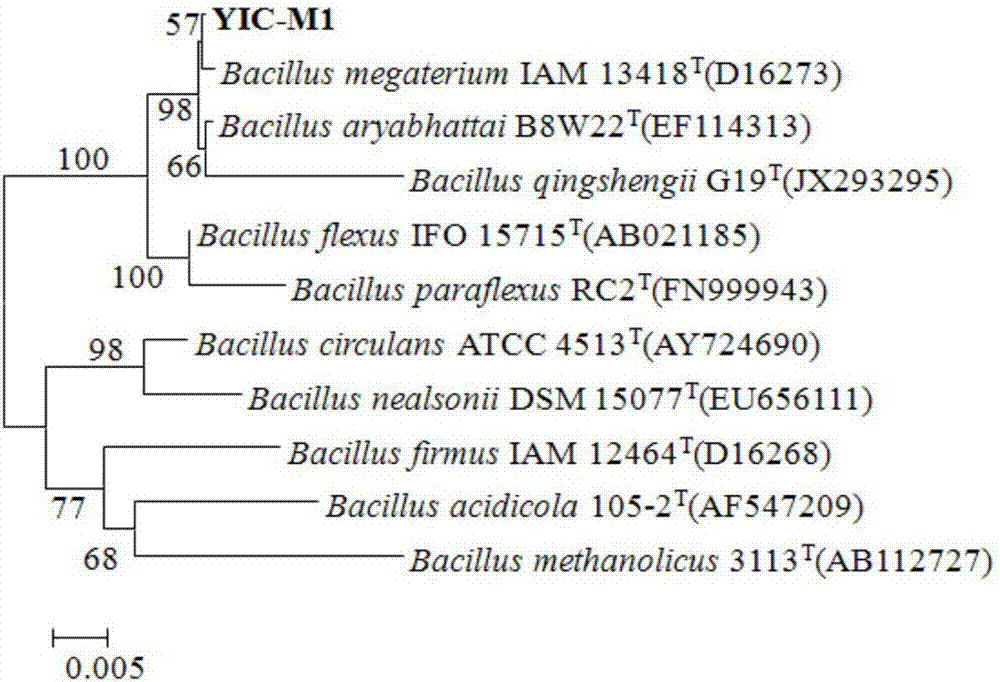

Production method of slow-release and synergistic fucoidan nitrogen fertilizer containing Bacillus megaterium

A technology of Bacillus megaterium and alginate ammonium, which is applied in microorganism-based methods, biochemical equipment and methods, nitrogen fertilizers, etc., can solve the problems of easy decomposition of additives, unstable long-term effect, and high production costs, and achieves high production efficiency. Effective number of viable bacteria, strong environmental adaptability, and the effect of improving utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Grinding the washed and dried fresh sargassum into 50-60 mesh powder;

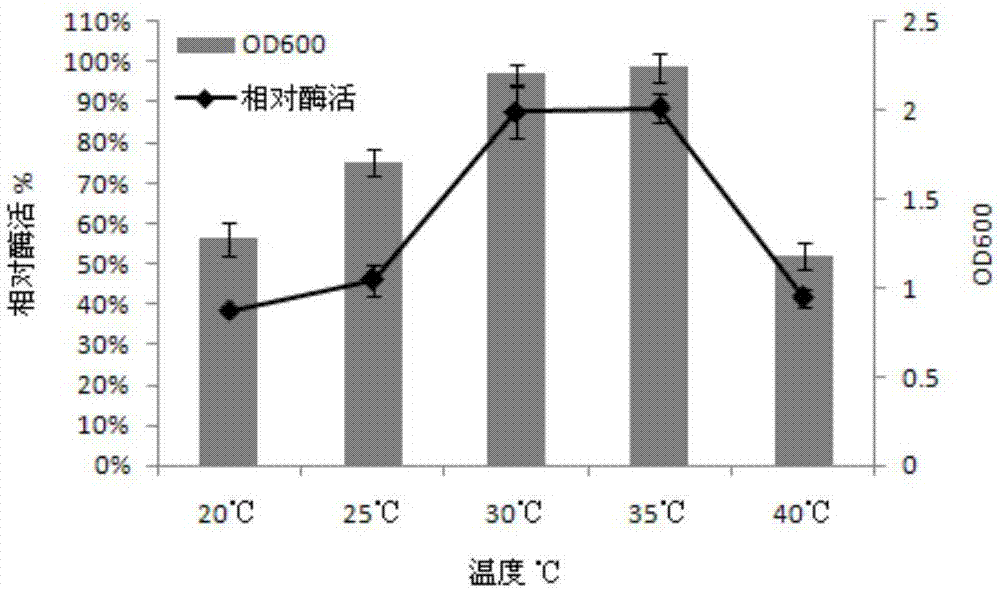

[0045]The seaweed powder and water are put into the fermenter according to the mass ratio of 2:100, and sterilized at 115°C for 30 minutes to obtain product A; and prepare the seed liquid: inoculate Bacillus megaterium YIC~BM1 into the liquid medium and cultivate it for 20 hours; The preservation number of the Bacillus megaterium YIC~BM1 is CGMCC No.12156; the liquid culture medium is: 5g of sodium alginate, 5g of ammonium sulfate, 1g of magnesium sulfate, 2g of dipotassium hydrogen phosphate, 0.01g of ferrous sulfate and distilled water 1000ml of the mixture, pH7.2~7.4; the volume ratio of Bacillus megaterium YIC~BM1 and culture medium is 2:100. Add the seed liquid to product A, wherein the mass ratio of seed liquid to product A is 1:100 to obtain product B; ferment product B at a temperature of 20°C and a pH of 5.5 to 6.0, and the fermentation time is After 7 days, product C was obtained; adjust ...

Embodiment 2

[0048] The washed and dried fresh copper algae and fresh sargassum are compounded according to the mass ratio of 1:1, and ground into 50-60 mesh powder;

[0049] Put seaweed powder and water into a fermenter according to the mass ratio of 6:100, sterilize at 115°C for 25 minutes to obtain product A; and prepare seed liquid: inoculate cellulase-producing Bacillus megaterium YIC~BM1 into liquid culture base, cultivated at 35°C for 24 hours; the preservation number of the cellulase-producing Bacillus megaterium YIC~BM1 is CGMCC No.12156; the volume ratio of the cellulase-producing Bacillus megaterium YIC~BM1 to the culture medium is 5 :100. The seed liquid is added to product A, wherein the mass ratio of seed liquid to product A is 10:100, and product B is obtained; product B is fermented at a temperature of 35°C and a pH of 6.0 to 6.5, and the fermentation time is After 8 days, product C was obtained; adjust the pH of product C to 5.5-6.0, and adjust the temperature to 5°C with...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap