Wine steaming and receiving device of distilled wine

A technology of distilling wine and distilling wine, which is applied in the preparation of alcoholic beverages, etc., can solve the problems of time-consuming and laborious, and achieve the effect of simple principle, easy promotion, and saving manpower and time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

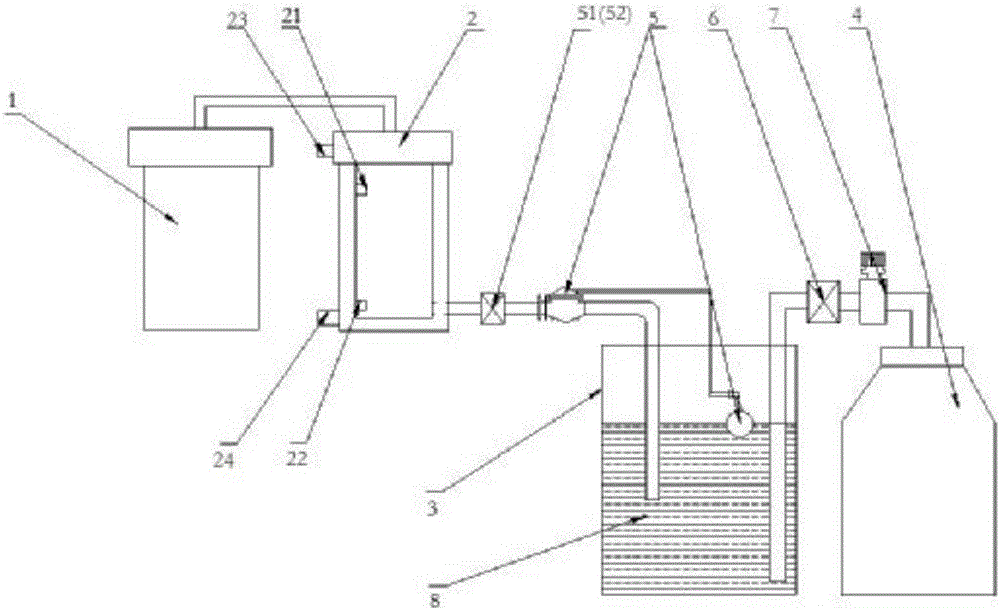

[0020] like figure 1 As shown, a distilled wine distilling wine receiving device includes a wine distiller 1, a wine cooler 2, a wine receiving container 3 and a wine vat 4. The outlet of the wine distiller 1 passes through the pipeline and the wine vapor at the upper end of the wine cooler 2 The inlet is connected. The wine cooler 2 includes an outer cylinder and an inner cylinder. The inner cylinder in the wine cooler 2 is connected to the wine receiving container 3 through a pipeline, and the pipeline is close to one end of the wine receiving container 3 and extends into the wine receiving container. 3 in.

[0021] A ball float valve 5 is provided on the pipeline connecting the inner cylinder body with the wine container, and the float ball of the ball float valve is located on the wine surface of the wine container 3. The installation of the ball float valve 5 ensures that the ball valve 5 is automatically closed when the wine container is closed. The wine surface in 3 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com