Manufacturing method for low-carbon thin strip steel containing acicular ferrite

A technology of acicular ferrite and manufacturing method, which is applied in the field of metallurgy, can solve problems such as high energy consumption, high cost, and complex production process, and achieve the effects of uniform distribution, fine structure, and complex production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

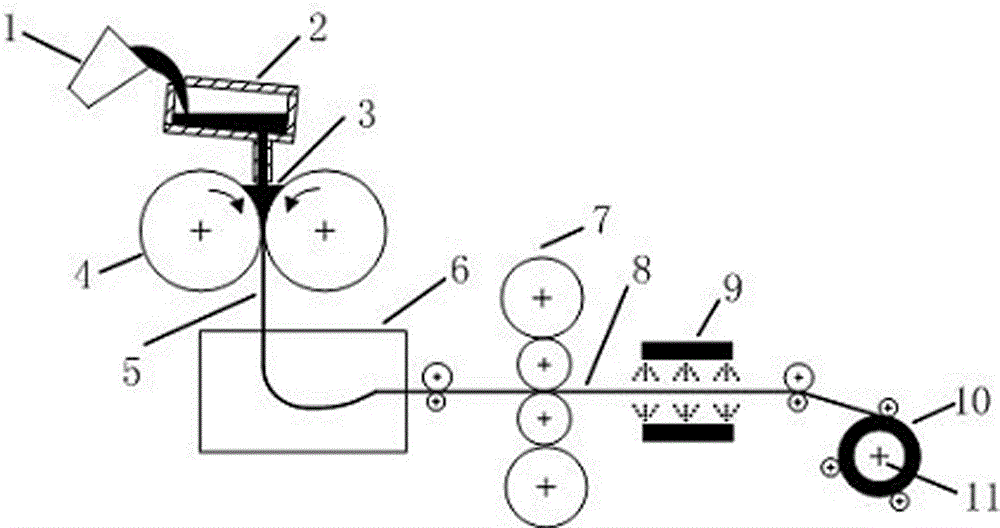

Method used

Image

Examples

Embodiment 1

[0024] The molten steel for smelting contains 0.16% of C, 0.6% of Si, 0.5% of Mn, 0.0028% of Al, 0.3% of Zr, 0.05% of P, 0.02% of S, 0.015% of O and 0.002% of N in terms of chemical composition, and the balance is Fe;

[0025] Preheat the tundish to 1100°C, pour the molten steel in the ladle into the twin-roll strip continuous casting equipment through the tundish, control the pouring temperature at 1540°C, and solidify the molten steel through the gap of the casting rolls and export it out at a speed of 35m / min to obtain a cast strip with a thickness of 2.5mm;

[0026] After the cast strip is exported, it is cooled to 1000°C at 15°C / s, and hot rolling is started to obtain a 2.0mm thick hot rolled plate;

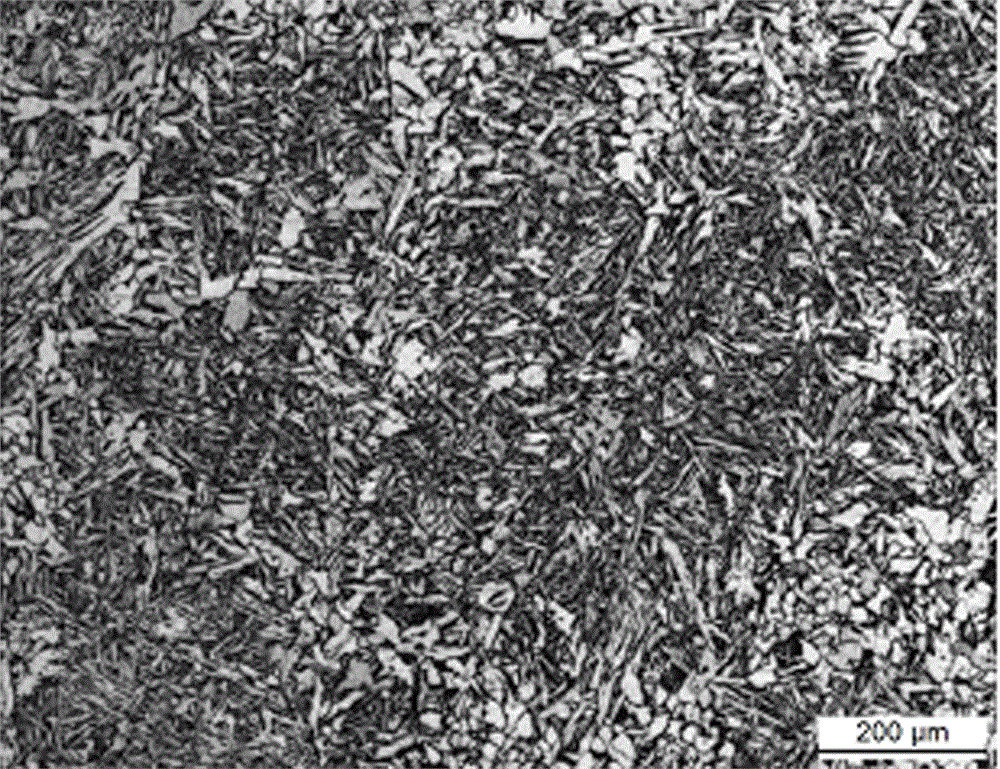

[0027] The hot-rolled sheet is water-cooled to 600°C for crimping, and the water-cooling rate is 30°C / s to obtain acicular ferrite-containing low-carbon thin strip steel; The volume fraction is 80%, and the metallographic structure is as follows figure 2 As shown, the yi...

Embodiment 2

[0029] The molten steel for smelting contains 0.02% of C, 0.2% of Si, 0.7% of Mn, 0.0035% of Al, 0.3% of Zr, 0.05% of P, 0.02% of S, 0.015% of O and 0.002% of N in terms of chemical composition, and the balance is Fe;

[0030] Preheat the tundish to 1150°C, pour the molten steel in the ladle into the twin-roll strip continuous casting equipment through the tundish, control the pouring temperature at 1540°C, and solidify the molten steel through the gap of the casting rolls and export it out at a speed of 35m / min to obtain a cast strip with a thickness of 2.3mm;

[0031] After the cast strip is exported, it is cooled to 1000°C at 20°C / s, and hot rolling is started to obtain a 1.8mm thick hot-rolled plate;

[0032] The hot-rolled sheet is water-cooled to 600°C for crimping, and the water-cooling rate is 35°C / s to obtain acicular ferrite low-carbon thin strip steel; the acicular ferrite containing acicular ferrite low-carbon thin strip The volume fraction is 65%, the yield stre...

Embodiment 3

[0034] The molten steel for smelting contains 0.18% of C, 0.4% of Si, 0.5% of Mn, 0.002% of Al, 0.2% of Zr, 0.003% of P, 0.001% of S, 0.01% of O, and 0.004% of N in terms of chemical composition, and the balance is Fe ;

[0035] Preheat the tundish to 1170°C, pour the molten steel in the ladle into the twin-roll strip continuous casting equipment through the tundish, control the pouring temperature at 1520°C, solidify the molten steel through the gap of the casting rolls and export it out at a speed of 50m / min to obtain a cast strip with a thickness of 2.1mm;

[0036] After the cast strip is exported, it is cooled to 900°C at 25°C / s, and hot rolling is started to obtain a 1.5mm thick hot-rolled plate;

[0037]The hot-rolled sheet is water-cooled to 620°C for crimping, and the water cooling rate is 50°C / s to obtain acicular ferrite low-carbon thin strip steel; the acicular ferrite containing acicular ferrite low-carbon thin strip The volume fraction is 40%, the yield strength...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com