High-efficiency sterilization microbubble washing machine

A technology of micro-bubbles and washing machines, applied in the field of washing machines, which can solve the problems of no requirement for sterilization, difficulty in removing stains on clothes, unfavorable human body, etc., and achieve the effects of reducing stain residue, good cleaning effect, and excellent sterilization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

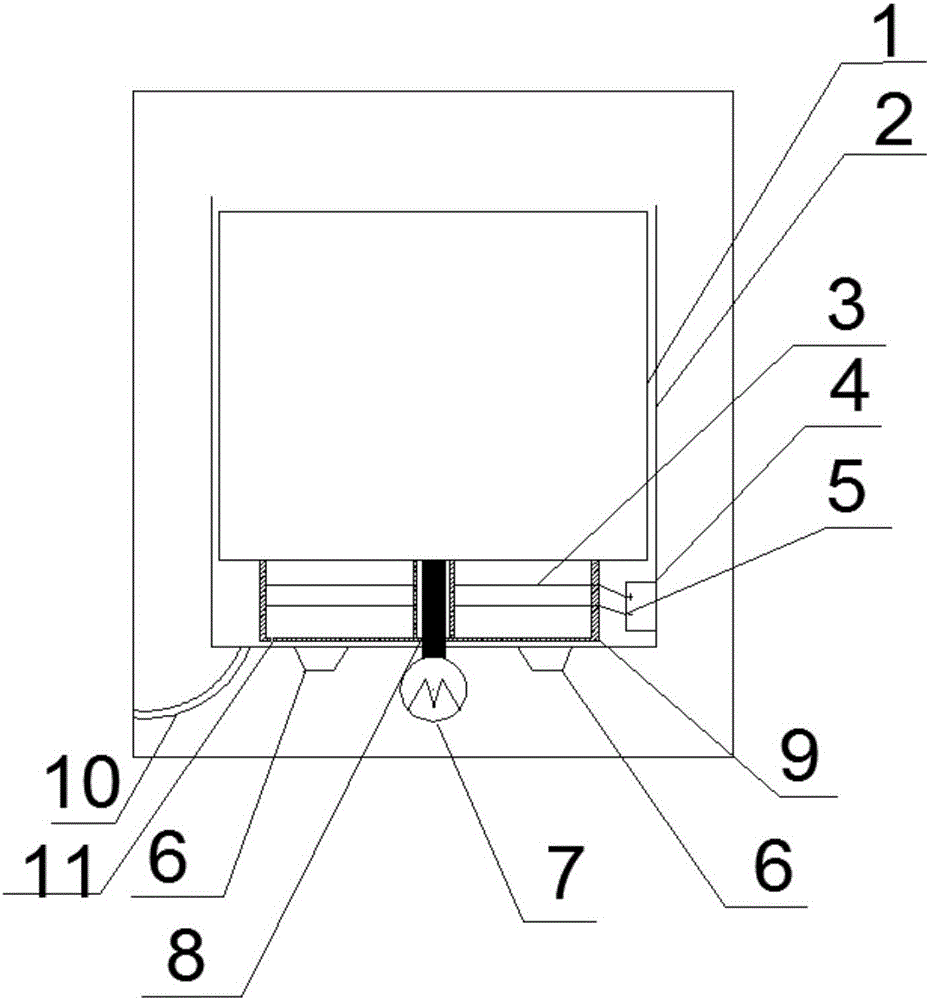

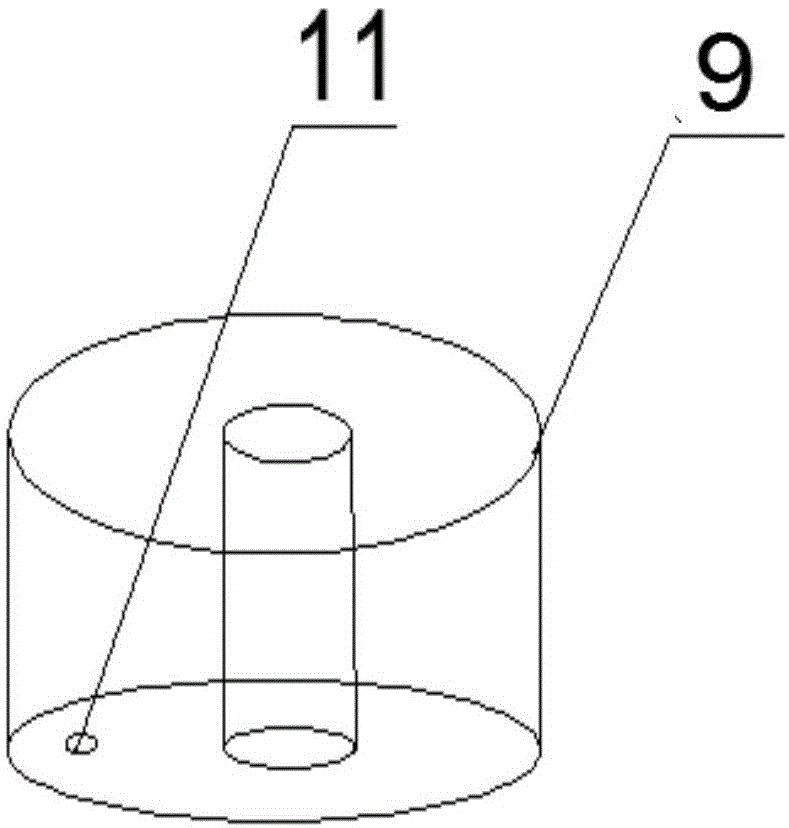

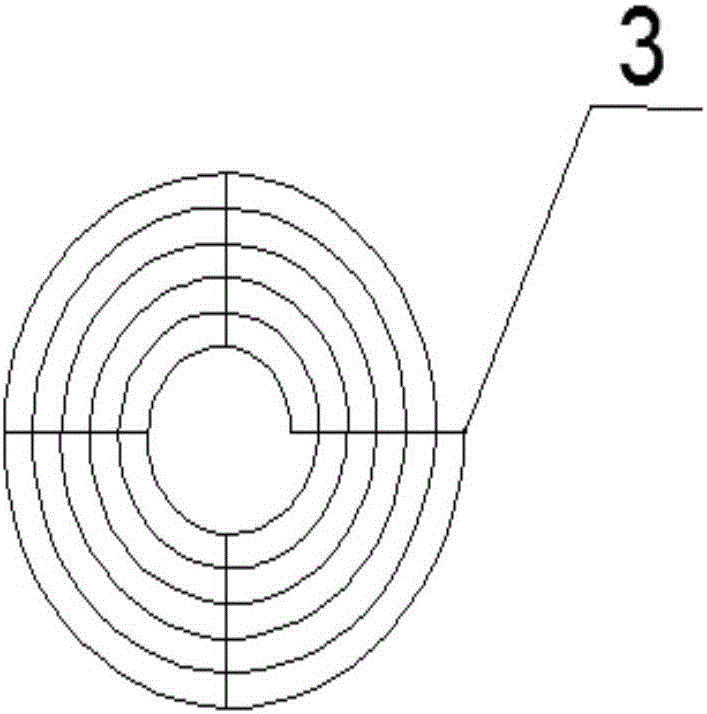

[0026] The present invention will be described in detail in conjunction with accompanying drawing now. This figure is a simplified schematic diagram only illustrating the basic structure of the present invention in a schematic manner, so it only shows the components relevant to the present invention.

[0027] Such as Figure 1-3 As shown, a high-efficiency micro-bubble washing machine for sterilization of the present invention includes an inner cylinder 1, an outer cylinder 2, an electrolysis device and an ultrasonic transducer 6, the inner cylinder 1 is placed inside the outer cylinder 2, and the electrolysis device It is arranged at the bottom of the inner cylinder 1 and between the inner cylinder 1 and the outer cylinder 2. The ultrasonic transducer 6 is located below the electrolysis device and is fixedly installed on the inner wall of the bottom of the outer cylinder 2. The bottom of the outer cylinder 2 is also provided with a motor 7 that drives the inner cylinder 1 to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com