Steam and dry iron evaporation cavity impurity collecting structure

An electric iron and steam technology, applied in hand irons, washing devices, textiles and papermaking, etc., can solve problems such as burns to users, complicated plug structure, etc., and achieve the effects of preventing steam leakage, convenient and quick operation, and reliable assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described below in conjunction with the accompanying drawings of the description.

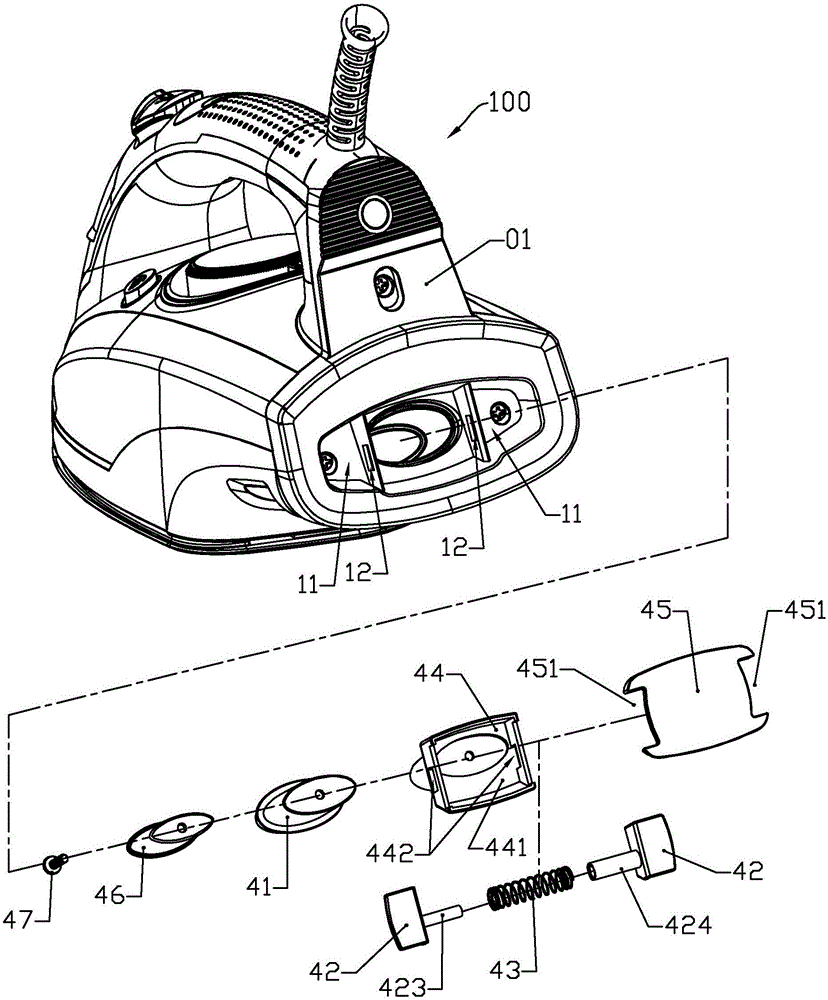

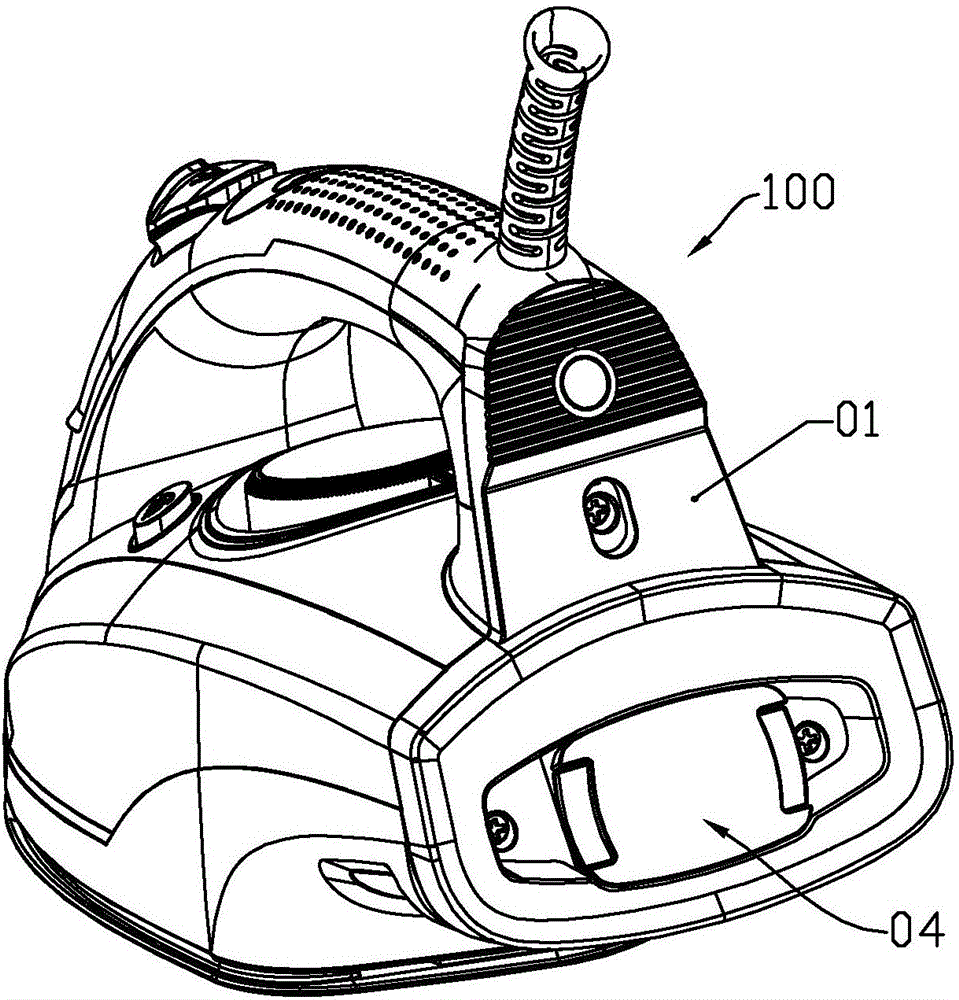

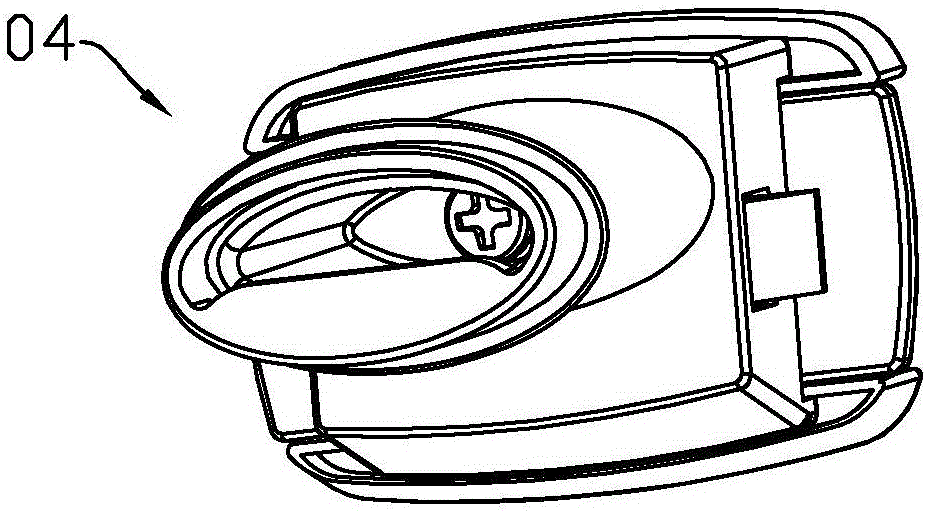

[0041] like Figure 1-9 As shown, the impurity collection structure of the vaporization chamber of the steam electric iron of the present invention is located at the rear of the steam electric iron 100, and includes a rear cover 01 and a connecting vaporization chamber 02 (see Figure 4 ) and the conduit 03 extending backward and upward and the collection box assembly 04 assembled on the rear cover to cooperate with the rear end of the conduit (see image 3 ), there is a recess 11 on the rear cover 01 for handling the collection box assembly (see figure 1 ), the collection box assembly 04 has a dirt collection box 41 extending into the conduit, the collection box assembly 04 has two locks 42, each lock 42 has a lock tongue 421, and the lock tongues on the two locks face away from Setting, the back cover 01 is provided with a lock hole 12 correspond...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com