Resilient pad, mold and method for manufacturing open track bed

A technology of elastic pads and rail bearing grooves, applied in the field of rail transit, can solve the problems of difficult quality assurance, heavy workload, time-consuming and labor-intensive, etc., and achieve the effect of difficult quality assurance, heavy workload, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

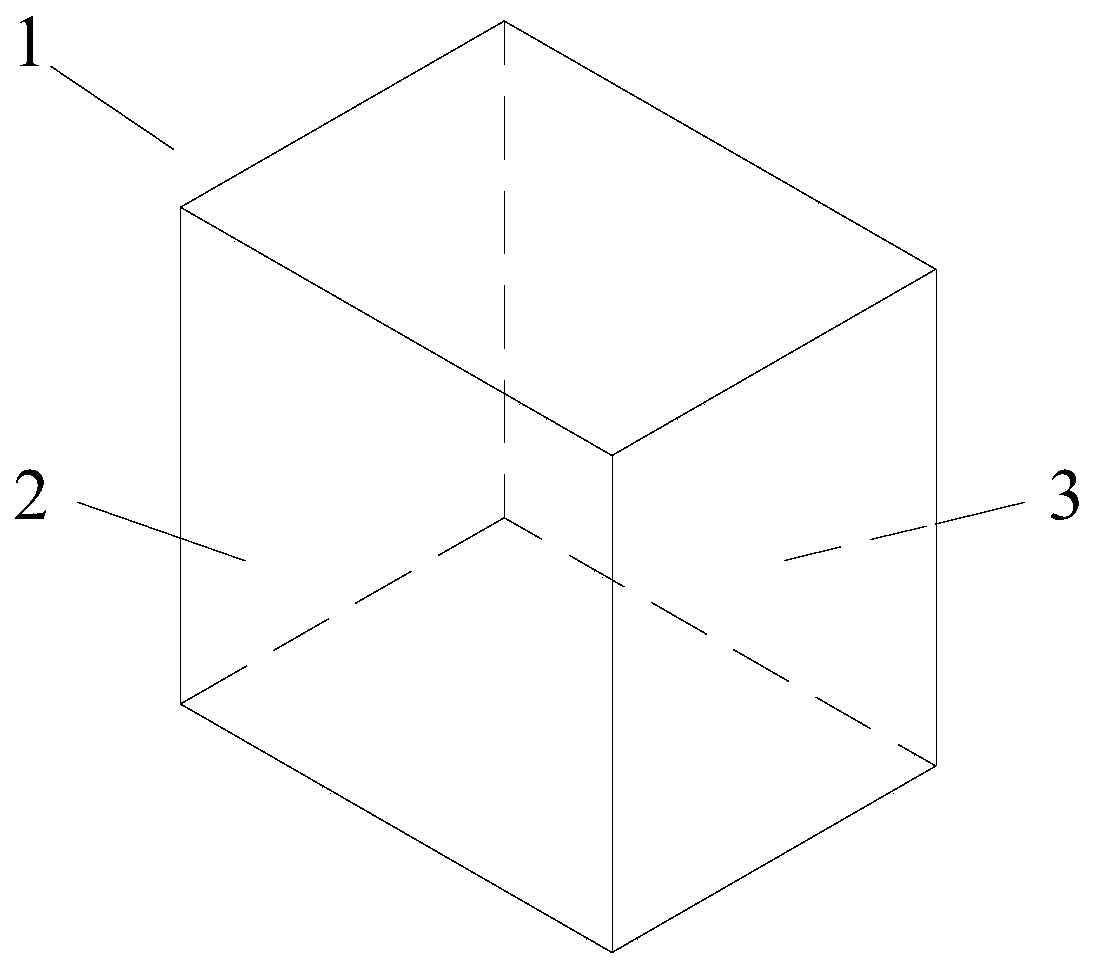

[0069] Such as Figure 3-16 As shown, the elastic pad 1 for manufacturing the open rail groove track bed according to the present invention.

[0070] The elastic pad 1 includes a fitting surface 1 and a fitting surface 2 3 which are arranged oppositely, and the elastic pad 1 is a columnar body, such as Figure 3-4 As shown, the shape of the fitting surface 1 is adapted to the cross-sectional shape of the end of the sleeper 4 .

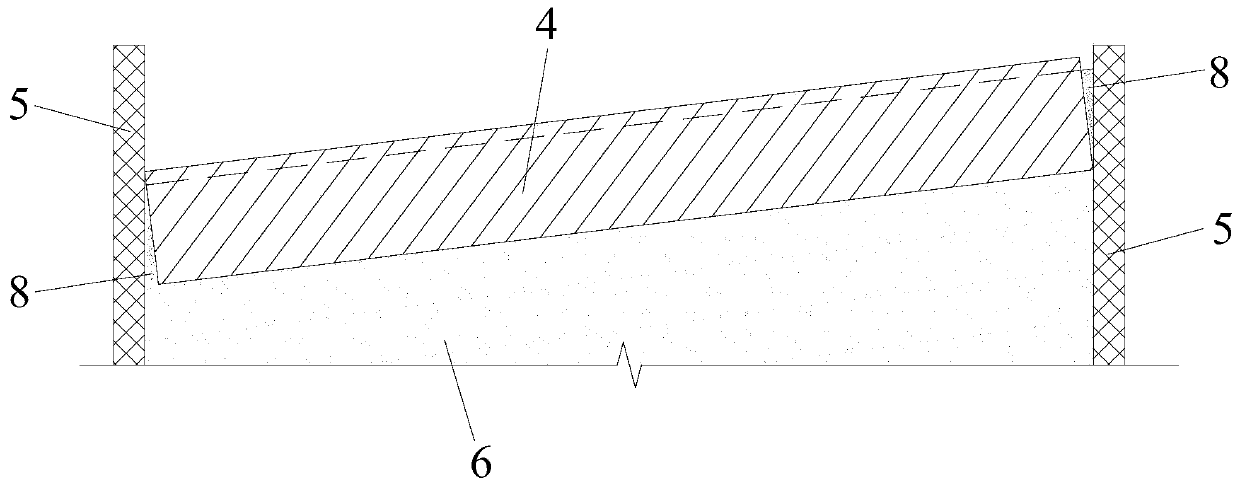

[0071] As a preferred solution of this embodiment, such as Figure 5-9 As shown, the area of the fitting surface two 3 is greater than the area of the fitting surface one 2, and the elastic pad 1 is in the shape of a table. With this structure, the elastic pad 1 of the table-shaped body makes the pouring The opening 7 of the rail bearing groove of the ballast bed 6 is in the shape of a bell mouth, that is, the sides and bottom of the rail bearing groove are opposite to the opening 7. The side walls of the ballast bed 6 have chamfered structures, ...

Embodiment 2

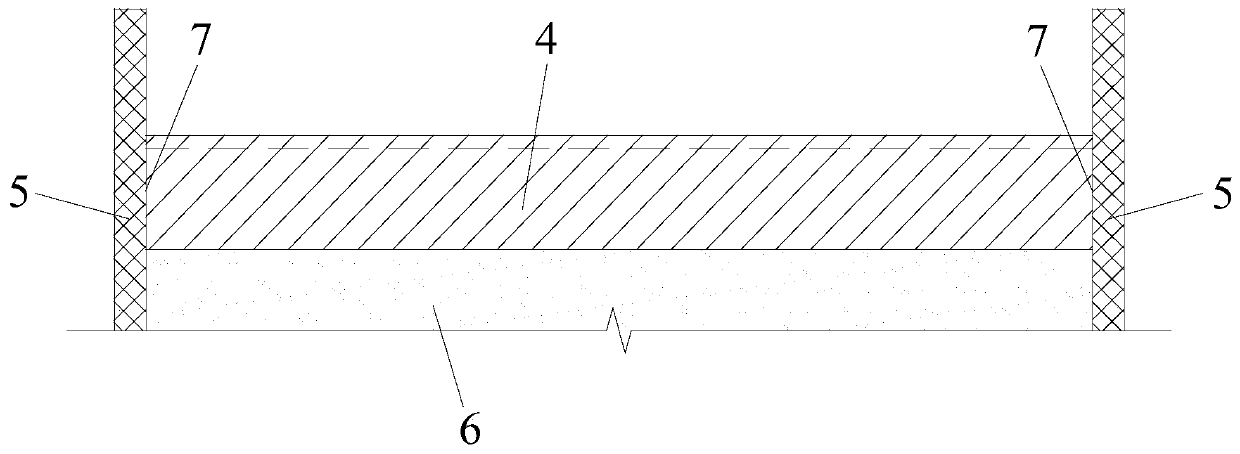

[0077] Such as Figure 3-23 As shown, the mold for manufacturing the open rail channel bed 6 according to the present invention includes the elastic pad 1 as described in Embodiment 1, and also includes a template 5 .

[0078] Such as Figure 13-16As shown, the formwork 5 encloses the frame required for pouring the ballast bed 6, the sleeper 4 is arranged in the frame, the end of the sleeper 4 is provided with an elastic pad 1, and each of the bonding surfaces One 2 is fixedly attached to the corresponding end surface of the sleeper 4 , and each of the said attached surfaces 2 3 is fixedly attached to the corresponding template 5 .

[0079] As a preferred solution of this embodiment, nuts are pre-embedded on the end faces of the sleeper 4, and each of the fitting surfaces 12 is bolted to the corresponding end face of the sleeper 4, and each of the fitting faces 23 is bolted. to correspond to the template 5.

[0080] Such as Figure 17-23 As shown, the mold also includes a ...

Embodiment 3

[0083] Such as Figure 3-23 As shown, the method for manufacturing open rail bearing groove ballast bed 6 according to the present invention, using the mold as described in Embodiment 2, comprises the following steps:

[0084] A. Support each sleeper 4, finely adjust the spatial geometric position of each sleeper 4, and fix all the sleepers 4;

[0085] B. The end faces of each of the sleepers 4 are fixedly connected to the bonding surface-2 of an elastic pad 1;

[0086] C. The formwork 5 is erected to form the frame required for pouring the ballast bed 6, and the formwork 5 located at the end of each sleeper 4 contacts and squeezes the bonding surface 2 3 corresponding to the elastic pad 1 respectively, and all the The fitting surface 2 3 is fixedly connected to the corresponding template 5;

[0087] D. The template 5 is fixedly connected to the foundation, and steel bars are set in the frame;

[0088] E. Pour concrete into the frame and maintain and form the ballast bed 6;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com