Swell-shrink type drainage device and sludge positive and negative pressure drainage method

A drainage device, positive and negative pressure technology, applied in soil protection, construction, infrastructure engineering and other directions, can solve the problems of small rebound amount of straw, limited cracks, and can not well overcome silt consolidation and blockage. The effect of reducing residual water, improving drainage efficiency, increasing air permeability and water permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

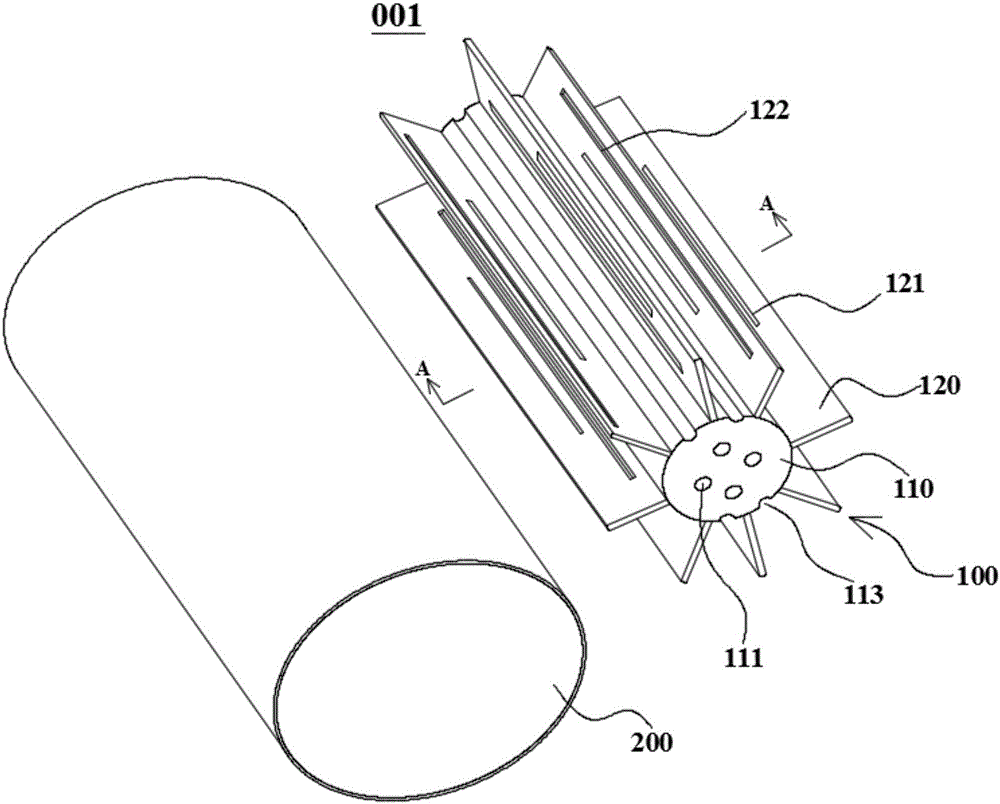

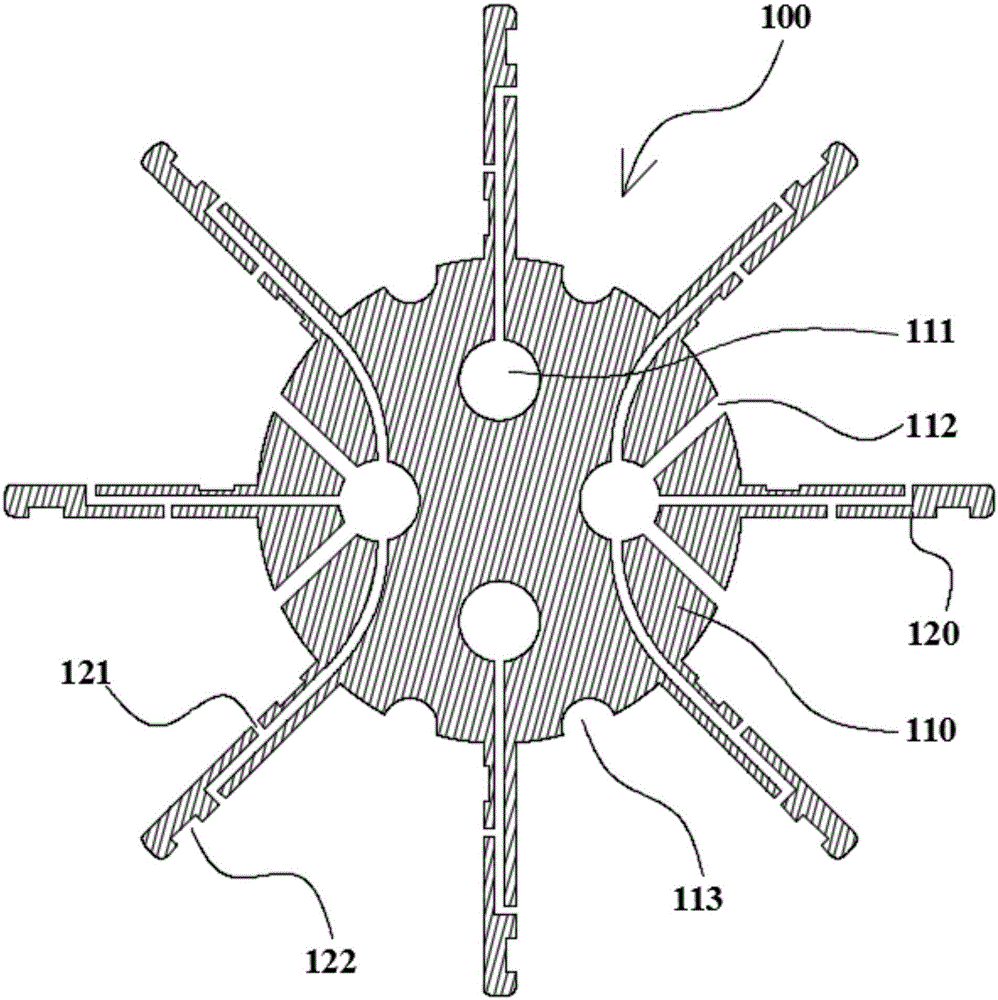

[0038] Please refer to figure 1 and figure 2As shown, this embodiment provides an expansion-contractable drainage device 001, which includes a drainage core 100 and a permeable filter cloth 200 wrapped on the drainage core 100. There is at least one radiating drainage portion 120 on the outer wall of the pipe body 110 , and at least one drainage channel 111 running through both ends of the drainage pipe body 110 is provided in the drainage pipe body 110 . Specifically, the drain pipe body 110 is cylindrical, and four drain channels 111 are arranged inside the drain pipe body 110, and each drain channel 111 runs through both ends of the drain pipe body 110. There are 8 strip-shaped radiation drains 120 , the distance between the edge of the radiation drain 120 away from the drain pipe body 110 and the outer wall of the drain pipe body 110 is equal to the radius of the drain pipe body 110 .

[0039] The expansion-contraction drainage device 001 can effectively prevent the slu...

Embodiment 2

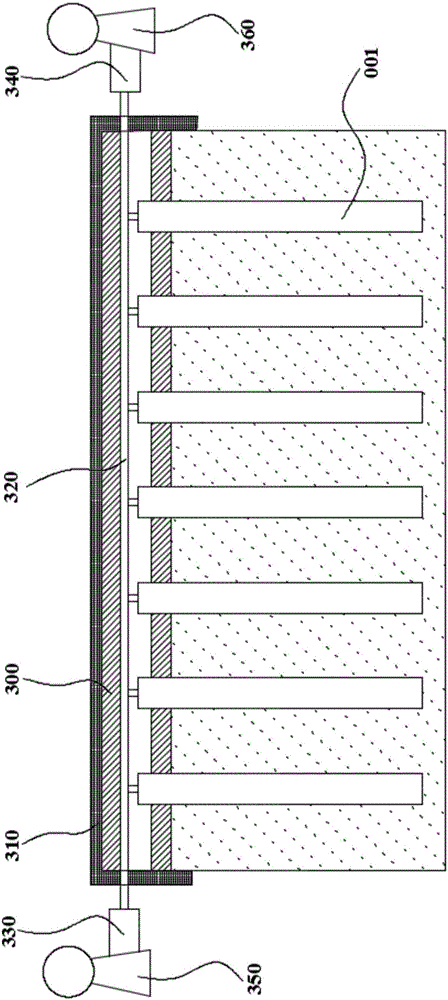

[0045] like image 3 and Figure 4 As shown, the present embodiment provides a positive and negative pressure drainage method for sludge, which comprises the following steps:

[0046] S201 , prepare the expansion-contraction drainage device 001 provided in Example 1, and wrap the permeable filter cloth 200 on the prepared drainage core 100 to obtain the expansion-contraction drainage device 001 .

[0047] S202. Build a construction floating body on the accumulated silt, and then lay a layer of geotextile 300 on the surface of the silt with the help of the construction floating body, and insert the prepared expansion-contraction drainage device 001 through the geotextile 300 at intervals into the silt; specifically, Each expansion-contraction drainage device 001 is vertically inserted into the mud according to the vertical and horizontal intervals, the distance between the expansion-contraction drainage devices 001 arranged in the longitudinal direction is 3m, and the distance...

Embodiment 3

[0054] like image 3 and Figure 4 As shown, the present embodiment provides a positive and negative pressure drainage method for sludge, which comprises the following steps:

[0055] S301 , prepare the expansion-contraction drainage device 001 provided in Example 1, and wrap the permeable filter cloth 200 on the prepared drainage core 100 to obtain the expansion-contraction drainage device 001 .

[0056] S302. Build a construction floating body on the accumulated silt, and then lay two layers of geotextiles 300 on the surface of the silt with the help of the construction floating body, and insert the prepared expansion-contraction drainage device 001 through the geotextile 300 at intervals into the silt; specifically, Each expansion-contraction drainage device 001 is vertically inserted into the mud according to the vertical and horizontal intervals, the distance between the expansion-contraction drainage devices 001 arranged in the longitudinal direction is 4m, and the dist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com