Foundation pit supporting system for subsurface structure close to soft ground stratum and construction method of foundation pit supporting system

A technology for underground structure and foundation pit support, which is applied in foundation structure engineering, excavation, construction, etc., can solve problems such as poor support effect, long construction period, and overall structural instability, and achieves reduction of foundation pit engineering risks, Solve the effect of occupying space and exerting investment benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] Below in conjunction with accompanying drawing and specific embodiment, feature of the present invention is further described:

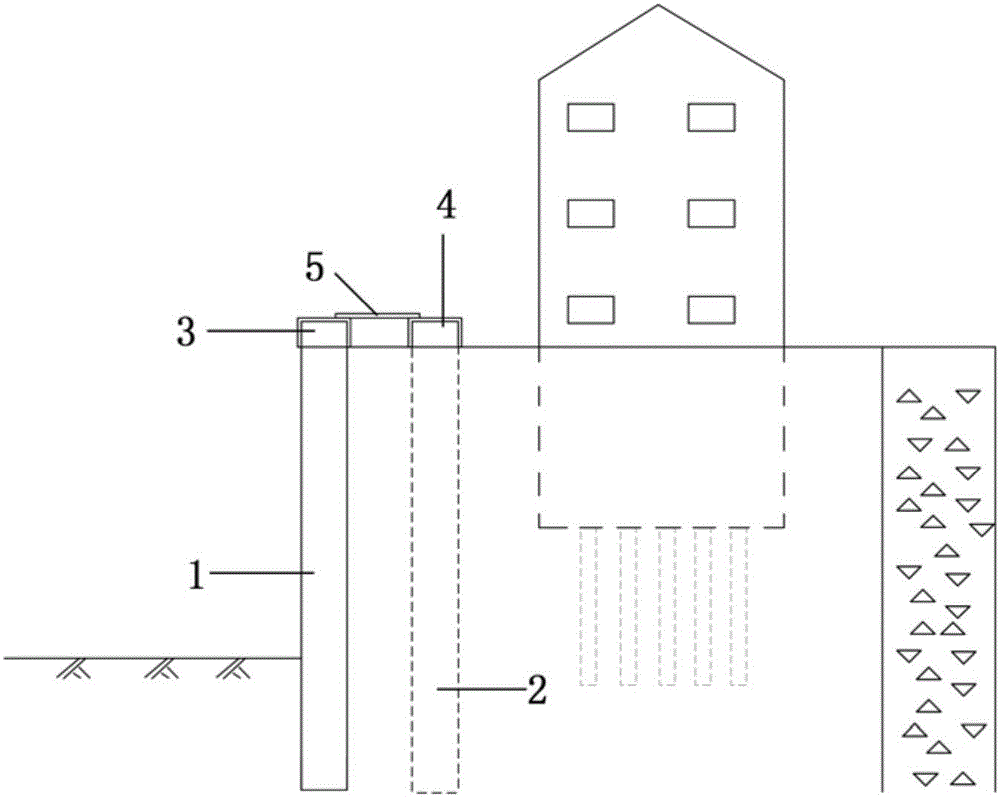

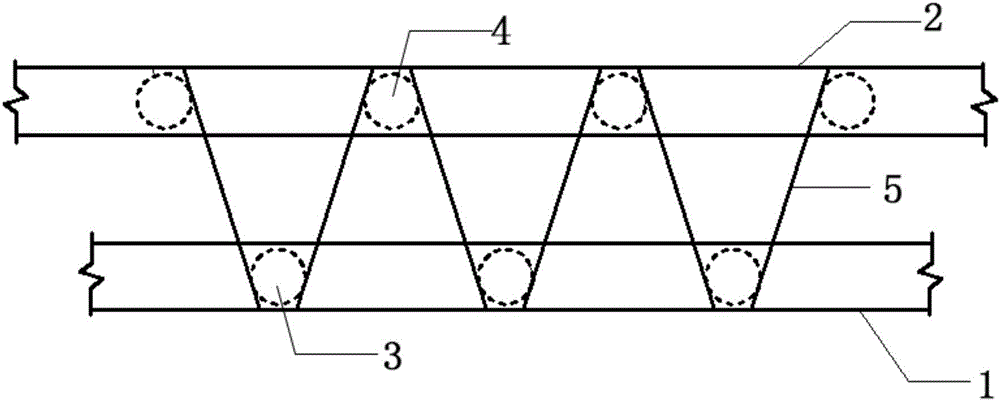

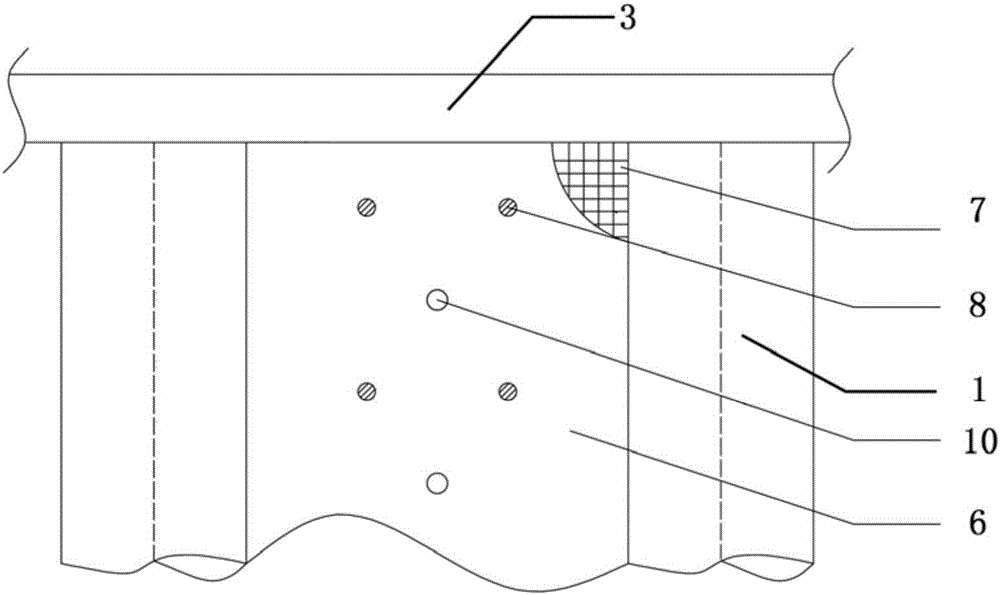

[0041] Such as Figure 1~4 As shown, the foundation pit support system used for weak ground adjacent to the underground structure includes the front row of steel pipe piles 1, the back row of steel pipe piles 2, the front row of pile crown beams 3, the rear row of pile crown beams 4, and the transverse connecting steel bars 5 , concrete surface 6, steel mesh 7 and soil nails 8;

[0042] There are multiple steel pipe piles 1 in the front row and steel pipe piles 2 in the back row. The steel pipe piles 1 in the front row and the steel pipe piles 2 in the back row are distributed in parallel along the wall of the foundation pit, and along the vertical direction of the wall of the foundation pit. staggered distribution;

[0043] The top of the front row of steel pipe piles 1 is provided with a front row of pile crown beams 3, and the top of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com