A Piezoelectric Energy Harvesting Bearing for Rotating Machinery

A piezoelectric energy harvesting and rotating machinery technology, applied in bearings, mechanical equipment, shafts and bearings, etc., can solve the problem of insufficient recycling and other problems, achieve simple and reasonable structure, ensure safety and reliability, and isolate the impact of noise. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

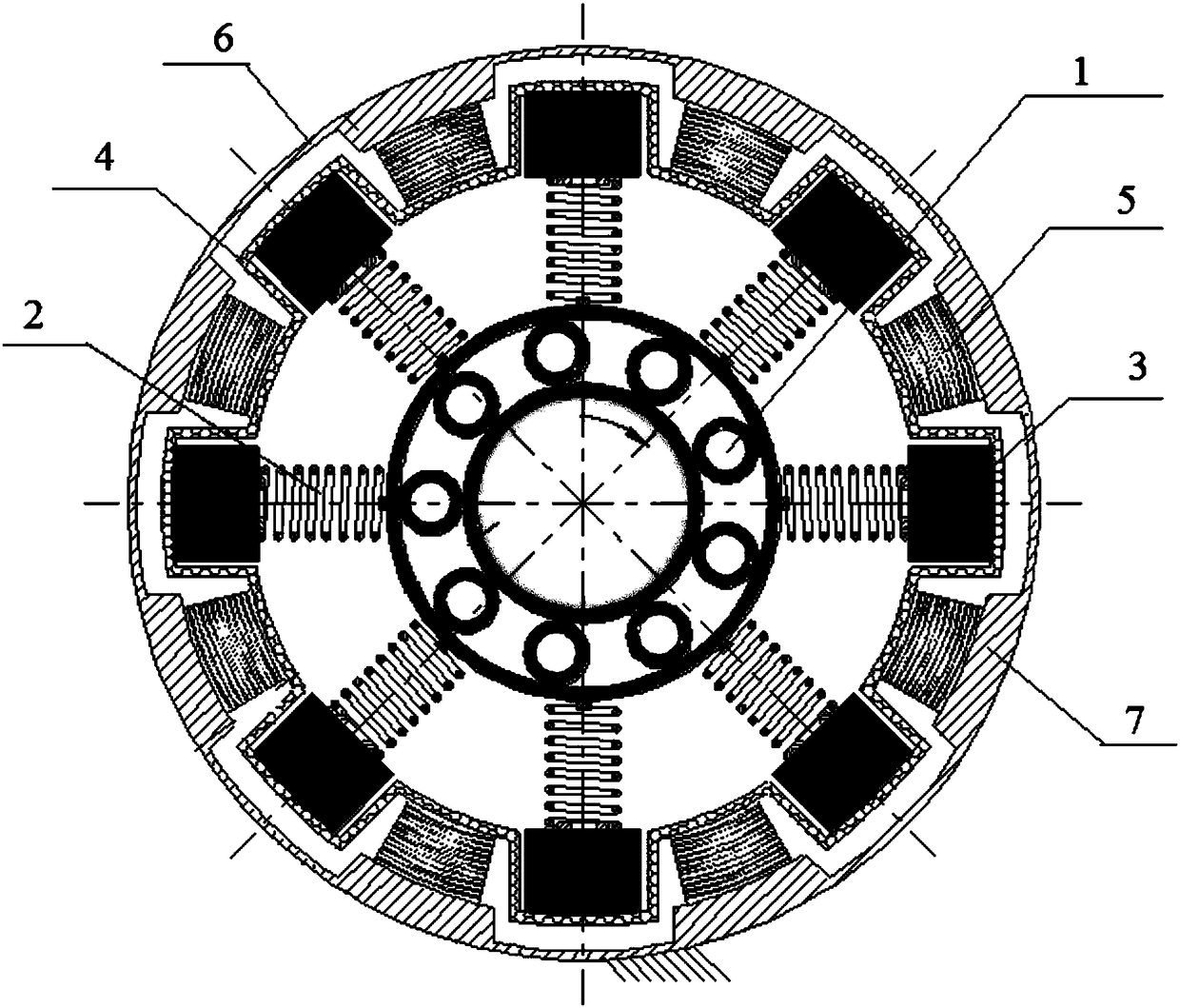

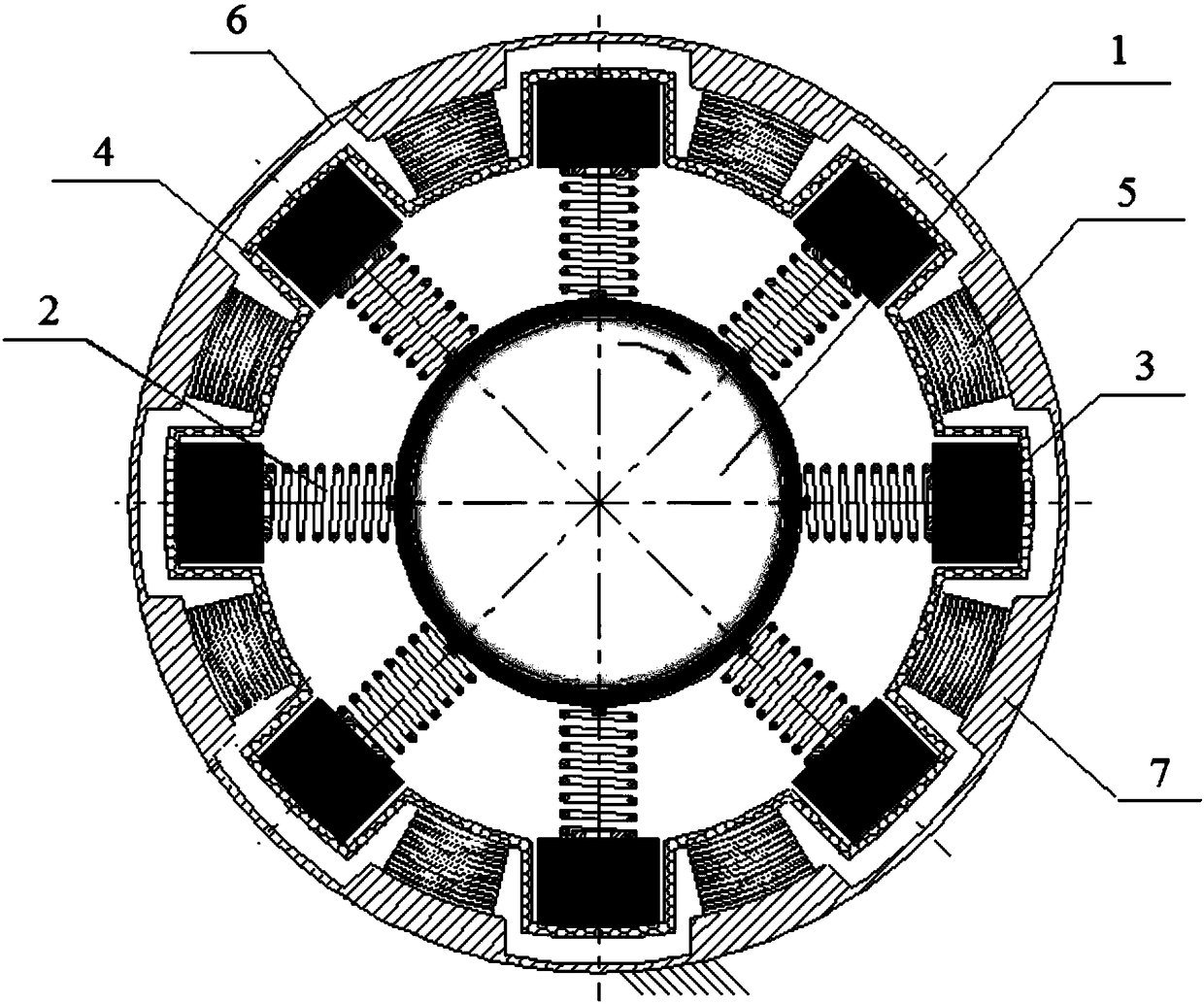

[0028] Such as Figure 1~2 As shown, this embodiment provides a piezoelectric energy-harvesting bearing for rotating machines, including a bearing body 1, which is characterized in that a plurality of springs 2 are uniformly arranged along the circumference of the bearing body 1, and along the stretching direction of the springs 2 A bracket 4 is sleeved, and the bracket 4 is ring-shaped, and the bracket 4 is processed into a uniformly distributed groove shape along its circumference, and the axis of the bracket 4 coincides with the axis of the bearing body 1; the bracket 4 of this shape can be Make full use of the effective space to make the structure more compact and save space; the centerline of the bracket 4 coincides with the centerline of the bearing body 1, and the bracket 4 is made of lightweight cored materials (such as metal foam aluminum cored materials), which can reduce mass;

[0029] One end of the spring 2 is connected to the bearing body 1, the other end of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com