Single-layer extension pipe

A telescopic tube and single-layer technology, applied in the direction of pipes, rigid pipes, pipes/pipe joints/pipe fittings, etc., can solve the problems of short service life, reduce production costs, simplify production processes, and avoid friction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solution of the invention is further described, but the present invention is not limited to these embodiments.

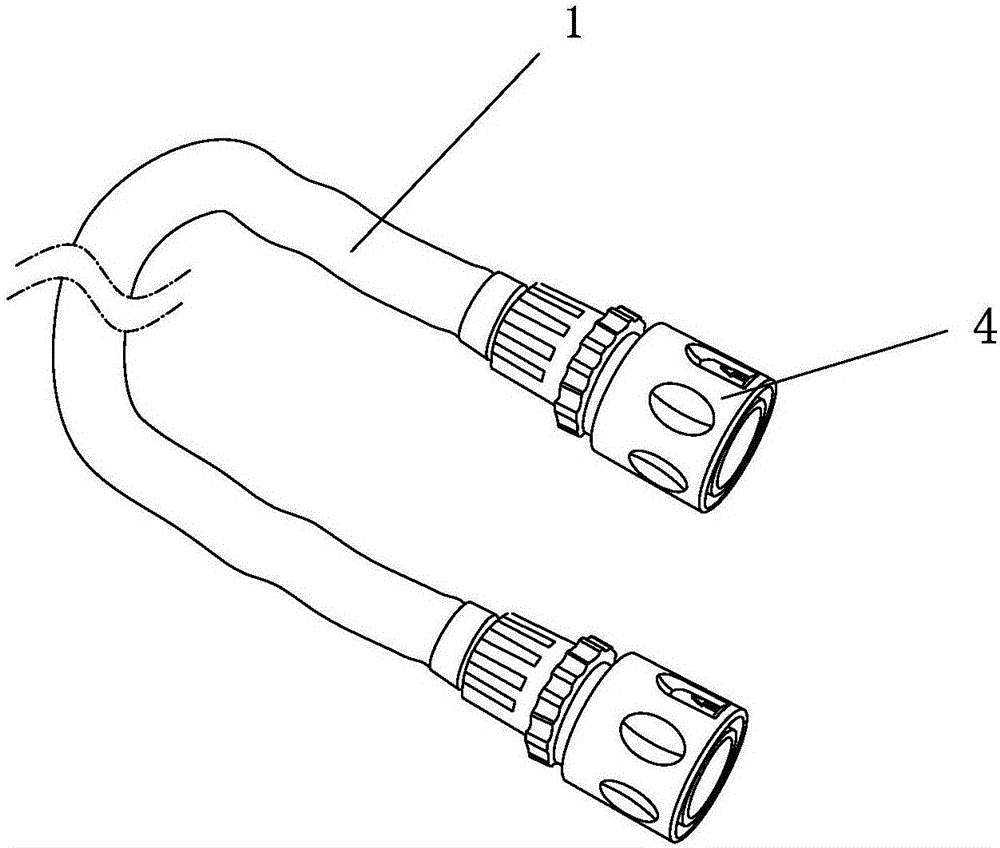

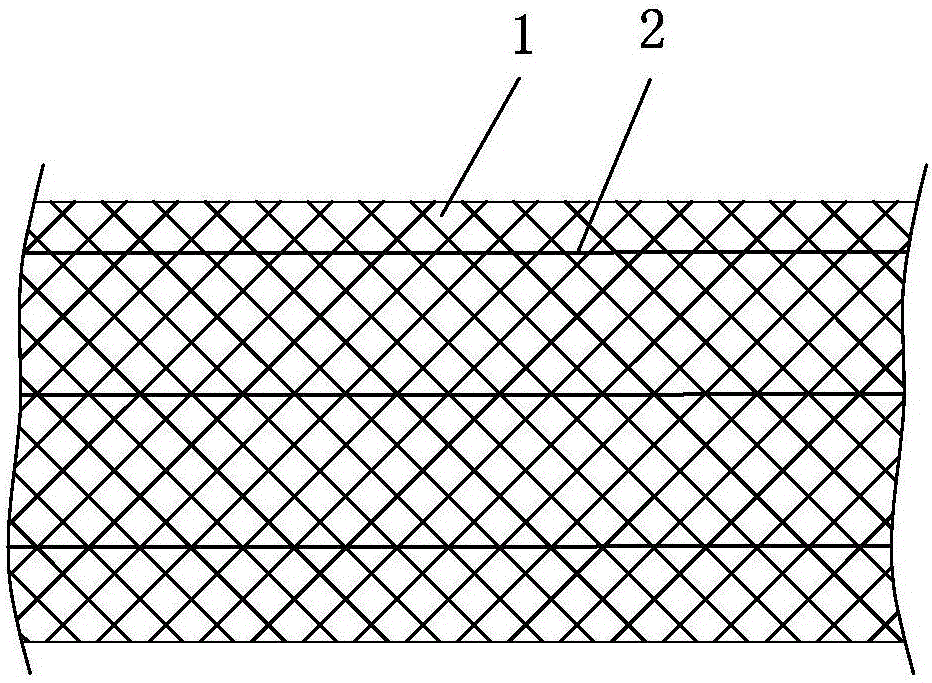

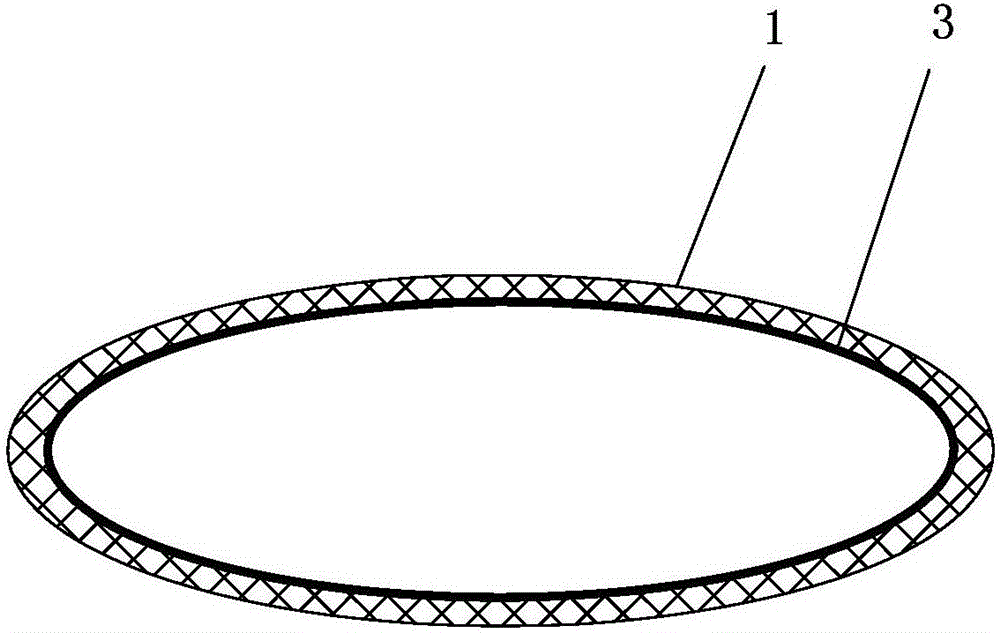

[0019] Such as Figure 1-3 shown. A single-layer telescopic tube, including a braided tube 1, on which a number of elastic threads 2 arranged axially along the braided tube 1 are arranged to form an elastic braided tube that can expand and contract in the axial direction. The inner or / or And the outer surface is provided with a rubber layer formed by dipping, that is, a rubber-soaked tube, or a rubber-lined layer 3 is provided on the inner tube wall of the elastic braided tube. The rubber-dipped elastic braided tube and the elastic braided tube provided with the rubber lining layer 3 still have the ability of axial expansion and contraction. And by means of rubber dipping and rubber lining, the elastic braided tube is formed into ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com