Main transformer oil level real-time monitoring method based on ultimate oil temperature equivalence method

A main transformer, real-time monitoring technology, applied in the liquid level indicator of physical variable measurement, etc., can solve the problems of reducing the service life of the transformer, economic loss, and untimely detection of oil leakage faults, so as to ensure accuracy and reliability , good compatibility and scalability, and the effect of improving the efficiency of operation and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] A method for real-time monitoring of the main transformer oil level based on the limit oil temperature equivalent proposed by the present invention is further described below in conjunction with the accompanying drawings and specific embodiments.

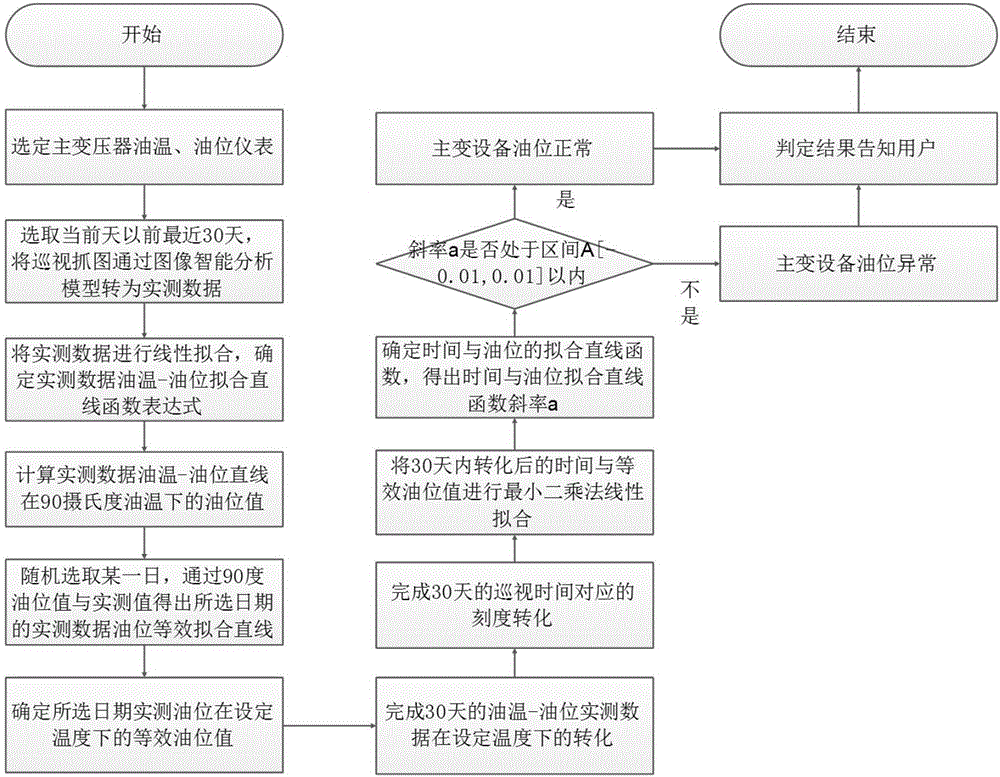

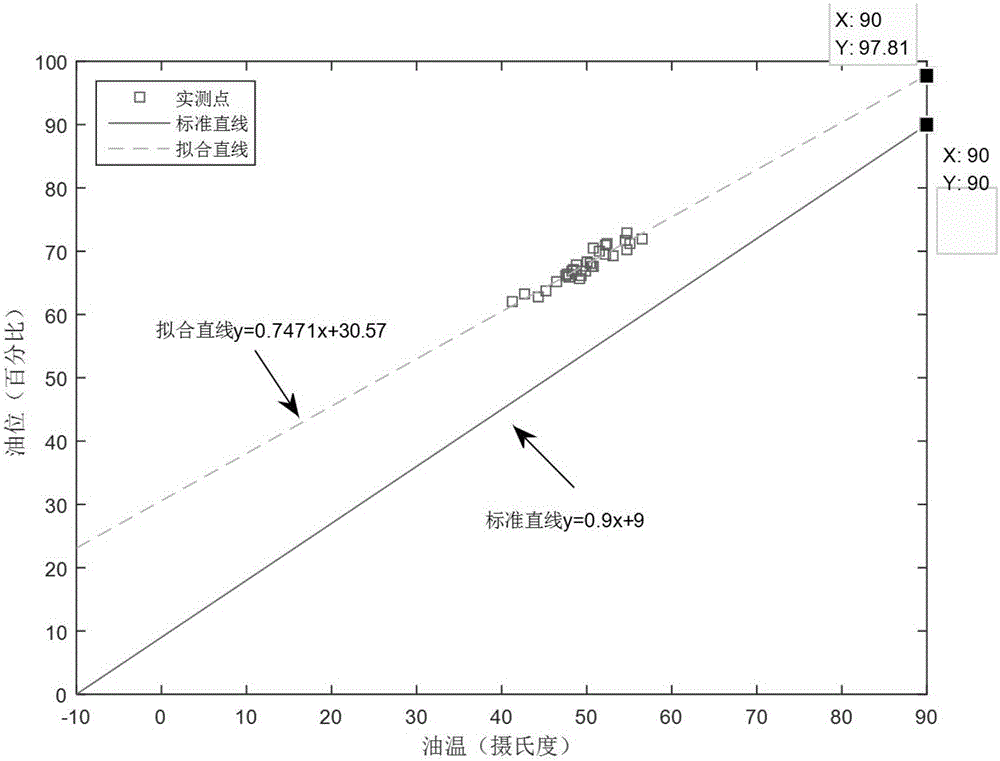

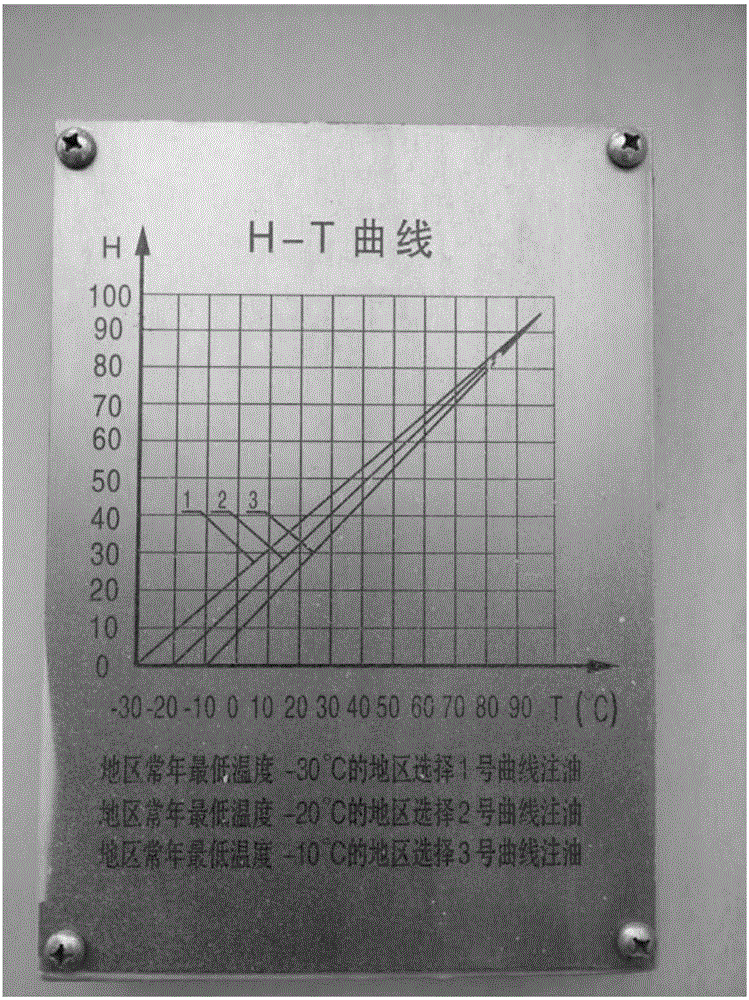

[0030] A method for real-time monitoring of the main transformer oil level based on the limit oil temperature equivalent proposed by the present invention, its flow chart is as follows figure 1 As shown, the method first obtains the measured data of oil temperature and oil level of a main transformer equipment in the last 30 days and performs linear fitting to obtain the oil temperature-oil level fitting linear function of the measured data and the oil level at an oil temperature of 90 degrees Celsius value; then use the measured data and the oil level value at 90 degrees Celsius to obtain the equivalent fitting straight line of the 30-day measured data oil level, and calculate the equivalent oil level value at the set tempera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com