Knob type shifter high and low-temperature durability test device with gear information monitoring function

A technology of durability test and gear shifter, which is applied in the direction of measuring device, vehicle test, mechanical component test, etc. It can solve the problem of failure and inability to comprehensively monitor the rotation angle of the sample, the state of the gear position information, the state of the solenoid electromagnet, Issues affecting the validity of the test, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

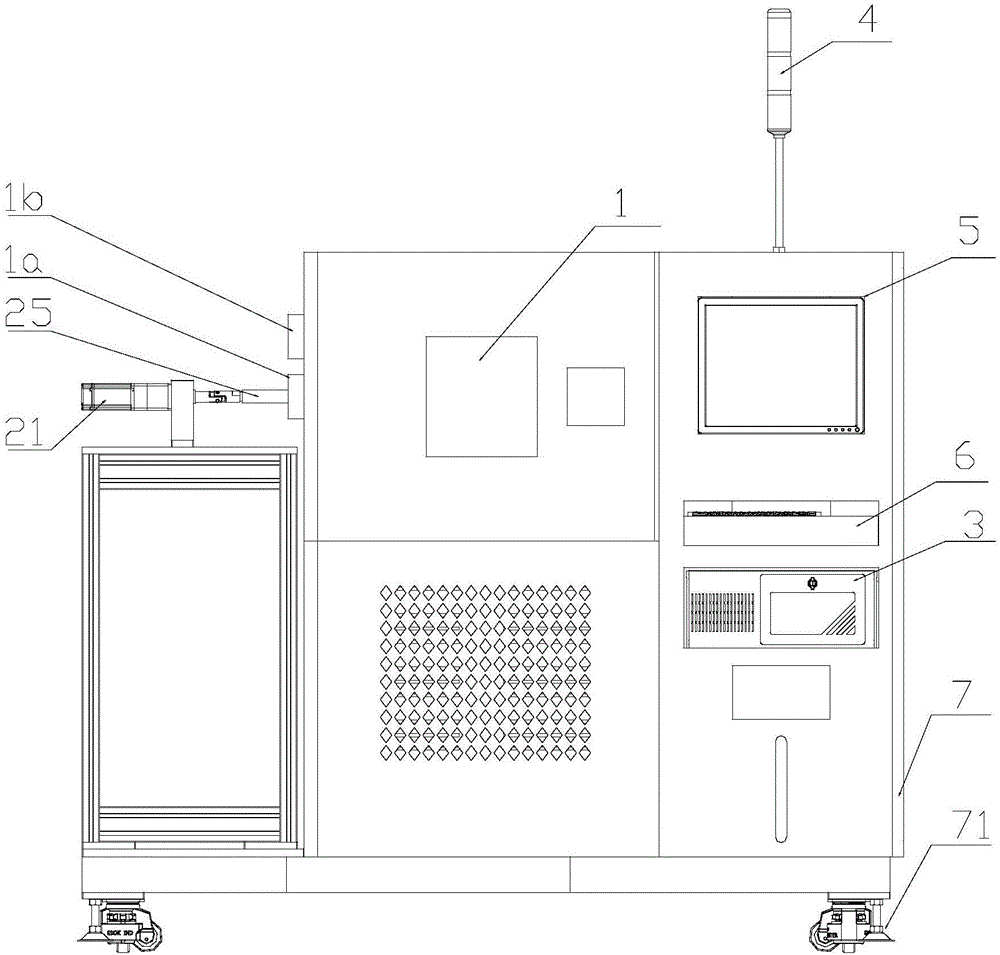

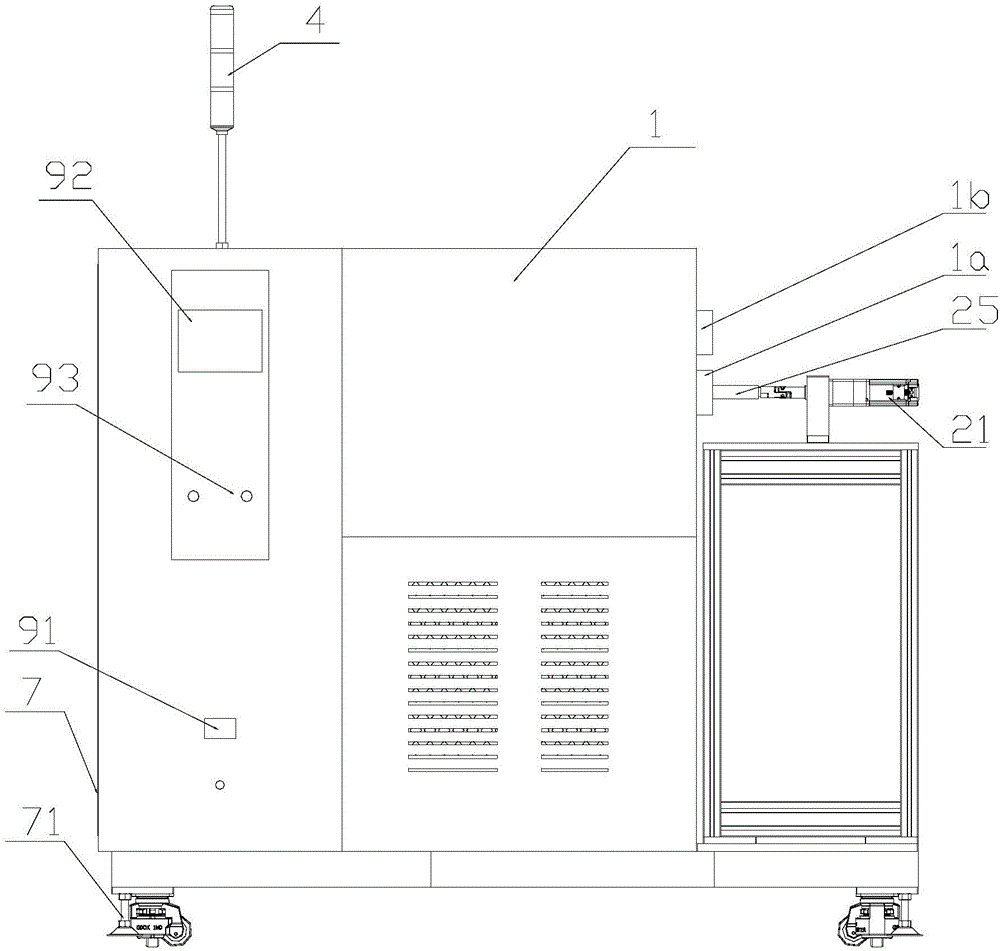

[0055] see figure 1 and figure 2 , as a preferred embodiment of the present invention: the present invention designs the high and low temperature endurance test device in a movable manner, specifically as follows:

[0056] The above-mentioned test box 1 is a sealed box with a shaft through hole 1a and a harness hole 1b on the box wall. The inner side of the door is provided with a sealing strip for sealing and sealing the box body.

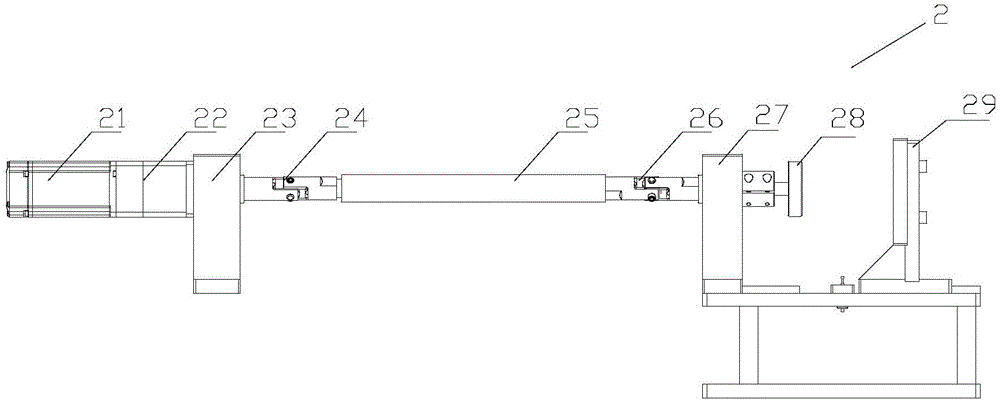

[0057] The above-mentioned second universal joint 26, second bearing 27, chuck tooling 28, shifter fixing tooling 29, temperature sensor and feedback mechanism 8 are all located inside the test box body 1, and the servo motor 21, reducer 22, first Both the bearing 23 and the first universal joint 24 are located outside the test box 1, the connecting shaft 25 passes through the shaft through hole 1a through the box wall of the test box 1, and the connection between the industrial computer 3 and the temperature sensor and the feedback mechanism 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com