Grain sampler

A sampling machine and grain technology, applied in sampling, sampling devices, measuring devices, etc., can solve problems such as inconvenient sampling operations and deviations in sampling detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

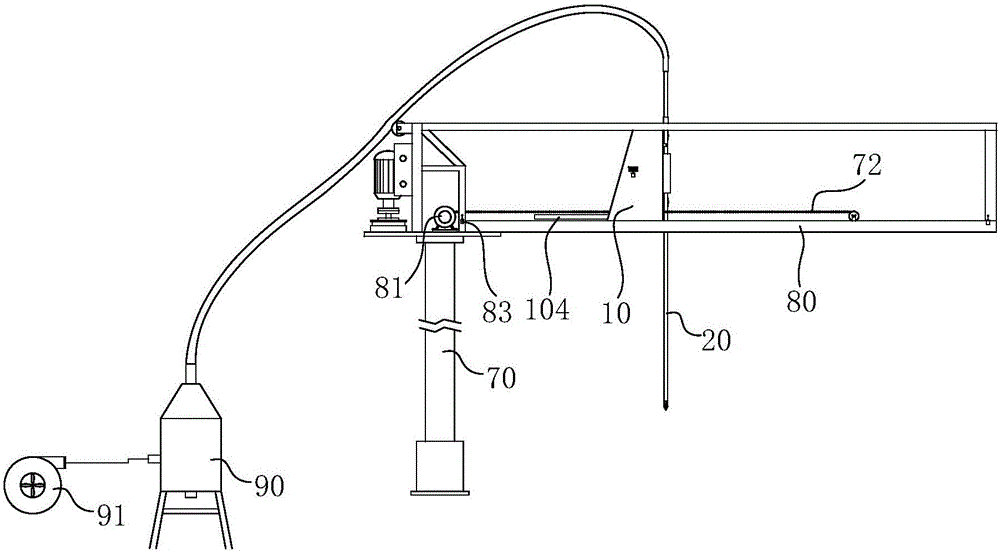

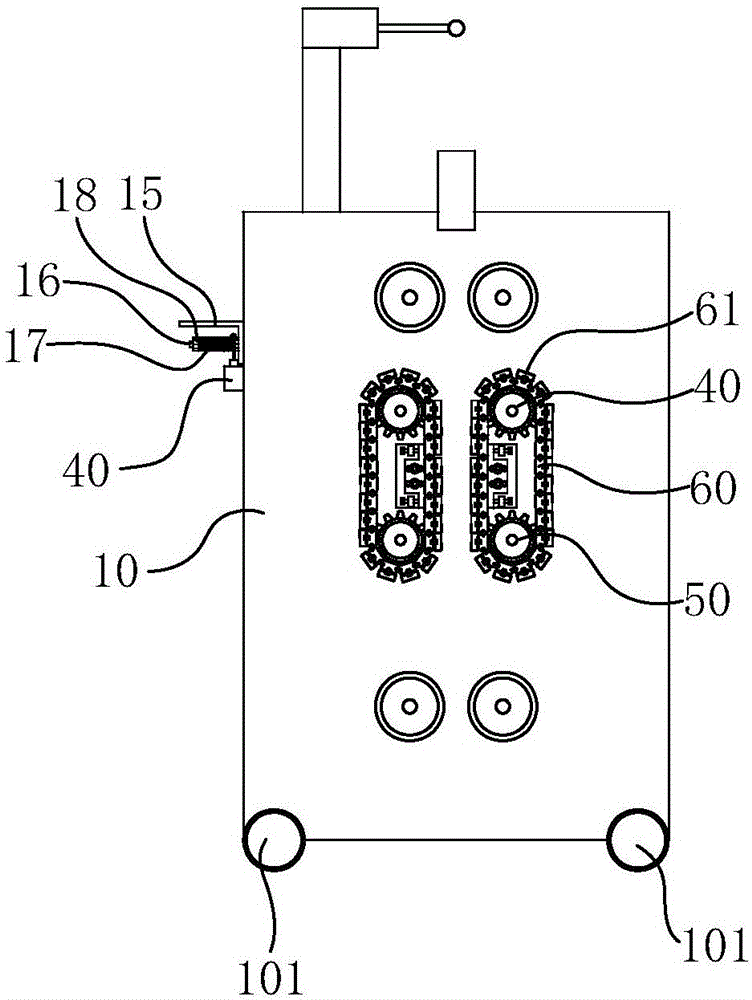

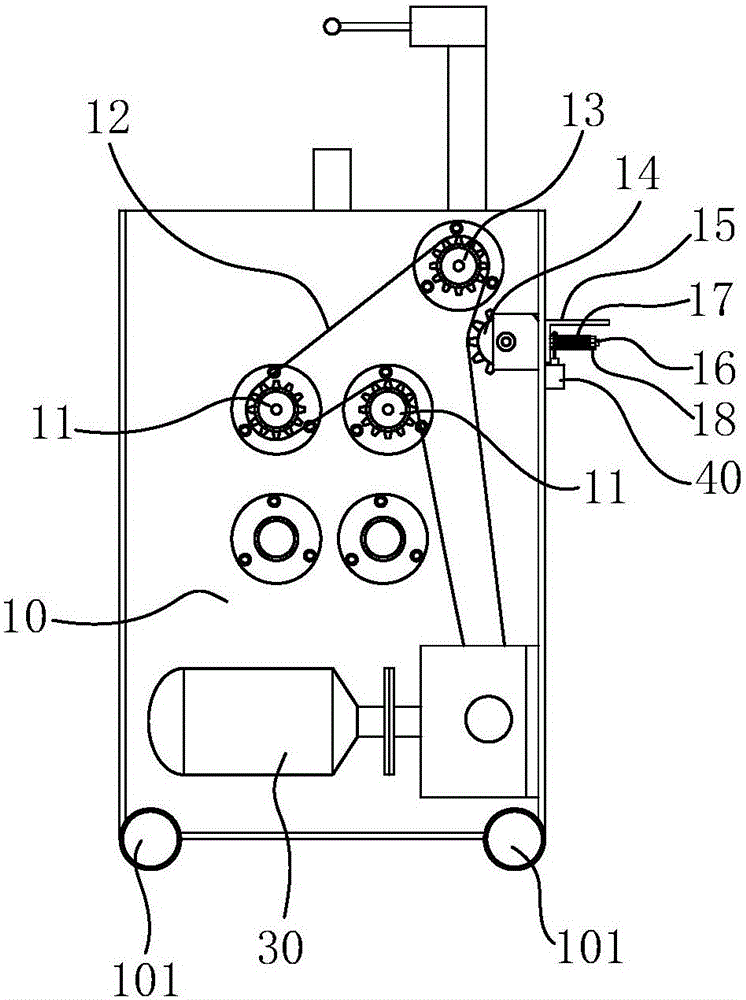

[0026] to combine Figure 1 to Figure 8 , the present invention is further described:

[0027] A kind of grain sampling machine, comprises column 70, is positioned at column 70 upper end and is arranged with horizontally extending cantilever frame 80, is provided with rotating mechanism between cantilever frame 80 and column 70, and rotating mechanism drives cantilever frame 80 to rotate around column 70, and described cantilever The frame 80 is provided with a mobile frame 10, and the driving mechanism drives the mobile frame 10 to reciprocate along the length direction of the cantilever frame 80. The mobile frame 10 is provided with first and second guide units, and the first and second guide units The area between the sending units constitutes the clamping port for clamping the sampling tube 20. The first and second guiding units all include a rotating shaft extending out from the moving frame 10, and driving wheels 11 are arranged on the rotating shafts. Two driving wheels...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com