Spent fuel transfer channel shielding device

A channel shielding and spent fuel technology, which is applied in shielding, nuclear power generation, climate sustainability, etc., can solve the problems of high dose rate around the fuel transfer channel, hinder the relative movement of the shielding body, and fail to meet the shielding requirements, etc., to achieve convenient construction , simple structure, and the effect of reducing maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

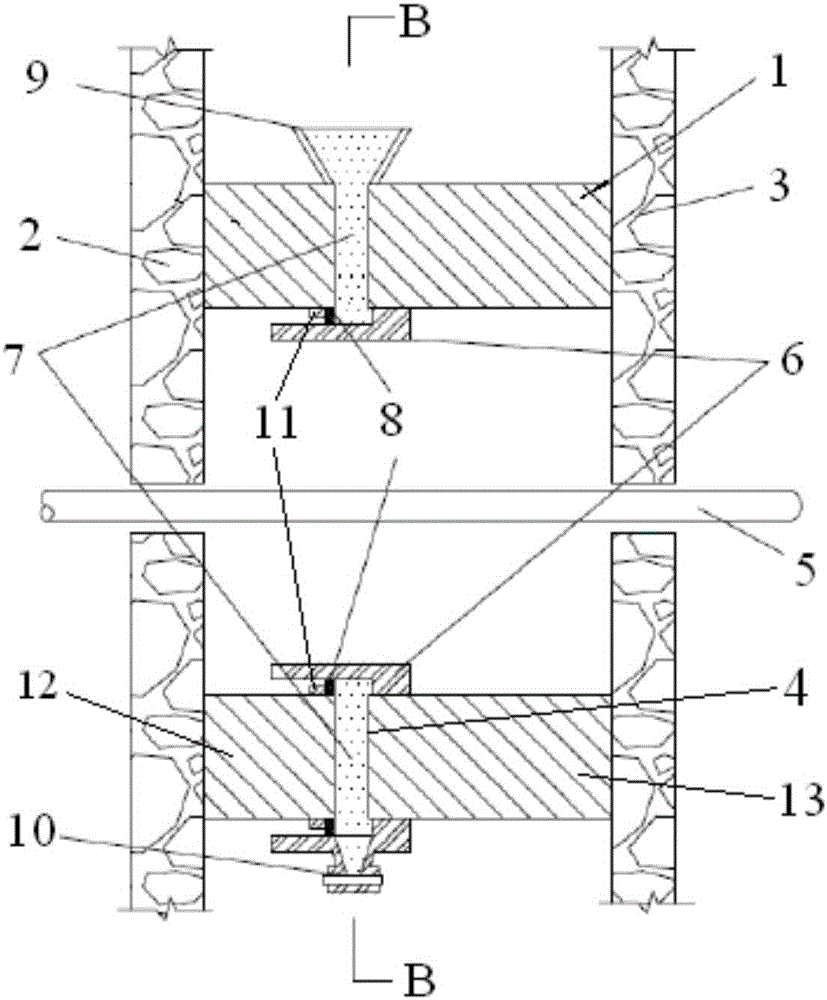

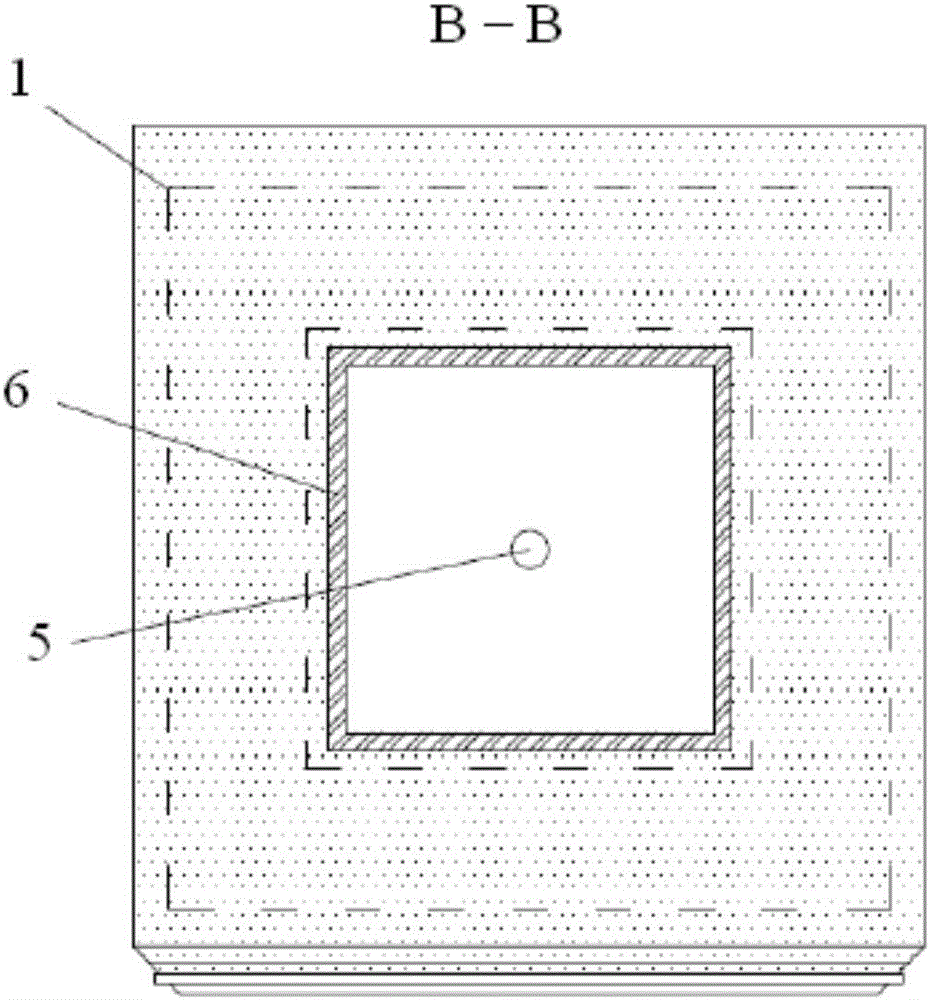

[0026] Such as figure 1 , 2 Shown is the shielding device for the spent fuel transfer channel provided by the present invention, the shielding device includes a shielding body 1, the shielding body 1 is a zigzag structure, and it is arranged in the fuel transfer channel between two adjacent buildings 2, 3 5 on. Expansion joints 4 are provided on the shielding body 1 to accommodate the relative displacement of the shielding bodies on both sides, thereby accommodating the relative movement between adjacent workshops. The expansion joint 4 is a straight gap, and the construction is relatively simple. The gaps are filled with lead borax to prevent beam leakage. The inner and outer sides of the expansion joint 4 are sealed with steel baffles to form a cavity with the shielding body of the fuel transfer channel at both end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com