Transferring operational platform for containers used in nuclear industry

An operation platform and nuclear industry technology, applied in nuclear engineering, portable protective containers, manufacturing tools, etc., can solve the problems of not providing sufficient connection strength, manual operation of the motor to eliminate danger, and inability to support the high-pressure environment of the container, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

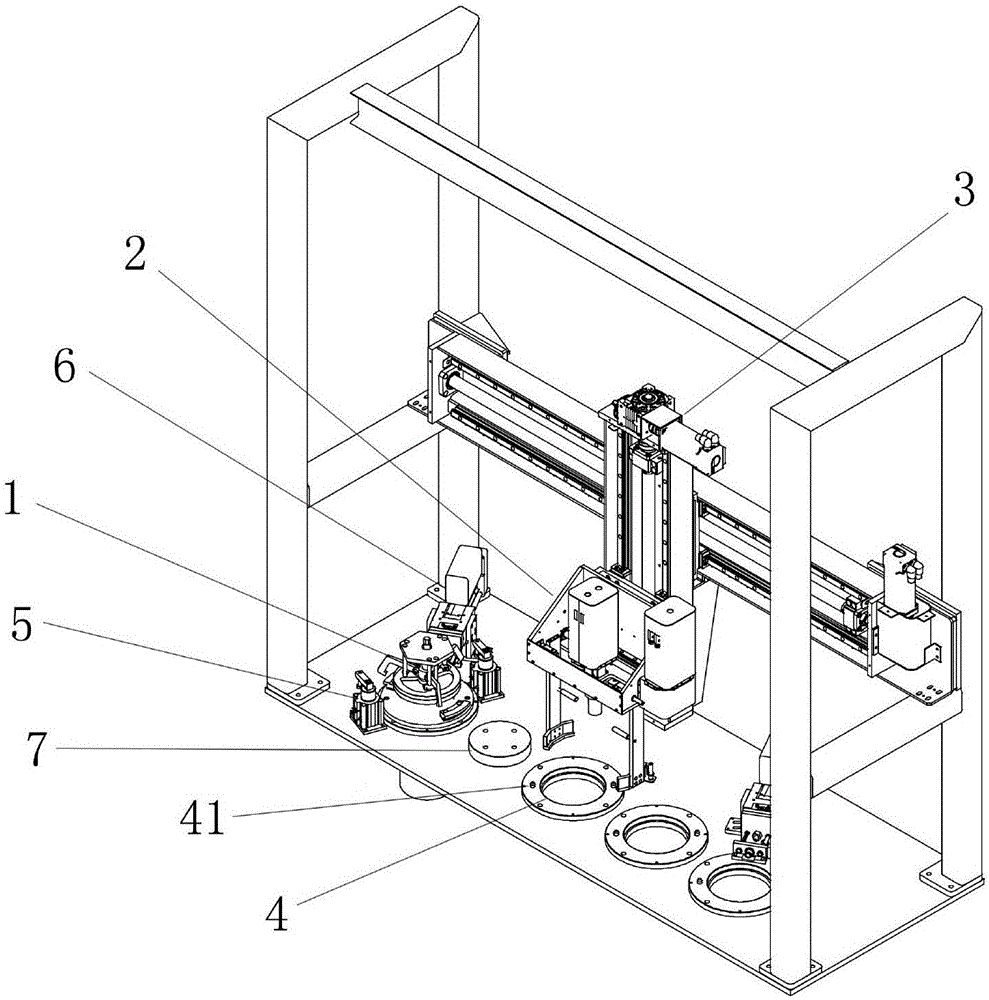

[0057] Such as figure 1 with 2 As shown, this embodiment includes a transfer robot 3 , an opening and closing gripper 2 and a container 1 , and the opening and closing gripper 2 is arranged on the transfer robot 3 and cooperates with the container 1 . The container 1 cooperates with the placement hole 4, the pressing mechanism 5, and the plug-in mechanism 6 provided on the platform. The placement hole 4 is provided with a positioning pin 41, and the end face of the positioning pin 41 is spherical. A matching positioning hole (not shown in the figure);

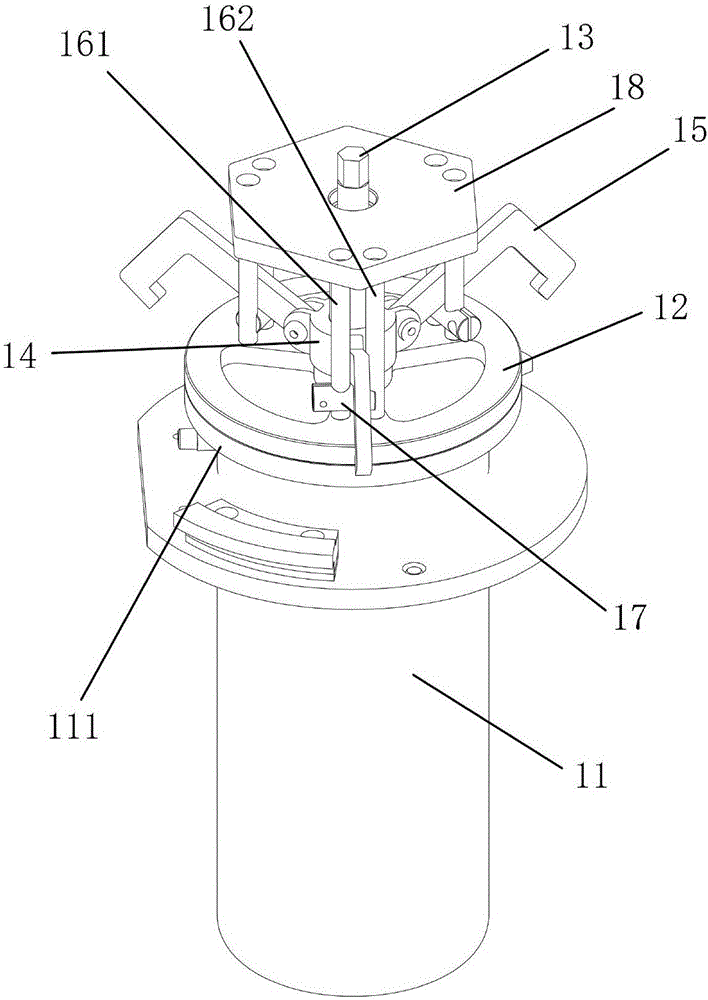

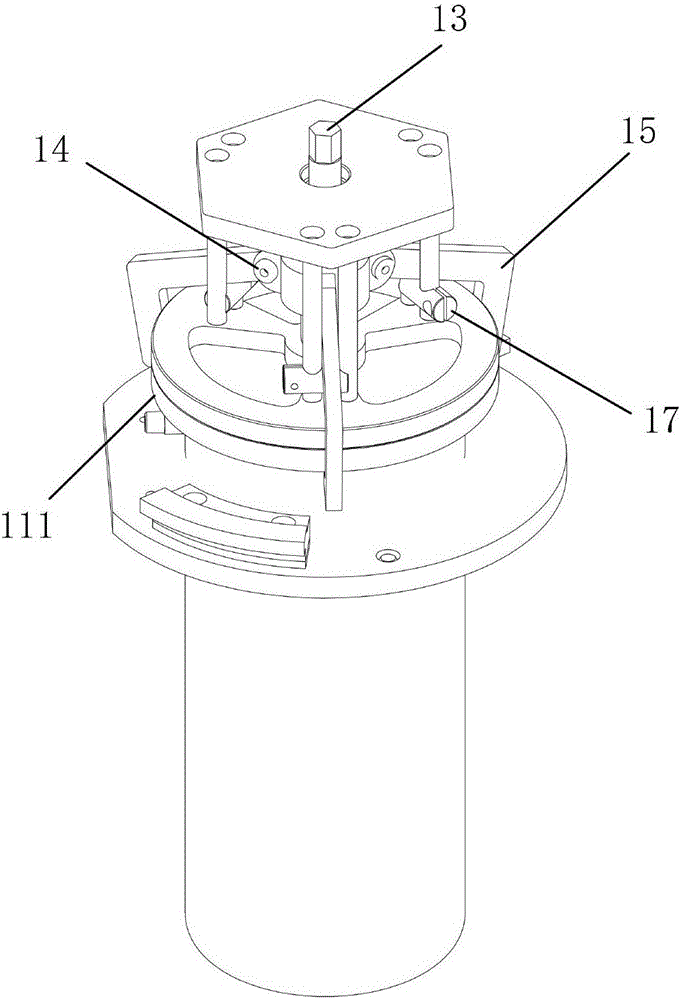

[0058] Such as figure 2 As shown, the container 1 includes a container body 11 and a cover body 12 , both of which are sealed by bonding, and a sealing ring can be provided at the seal of the container body 11 or the cover body 12 . Cooperate Figure 4 As shown, the center of the cover body 12 is provided with a circular notch, which can cooperate with the circular raised light ring below the rotating shaft 13, thereby lim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com