LED packaging structure

A technology of LED packaging and LED chips, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of poor color temperature uniformity, uncomfortable color temperature uniformity, hindering LED applications, etc., to increase light output rate and improve uniformity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

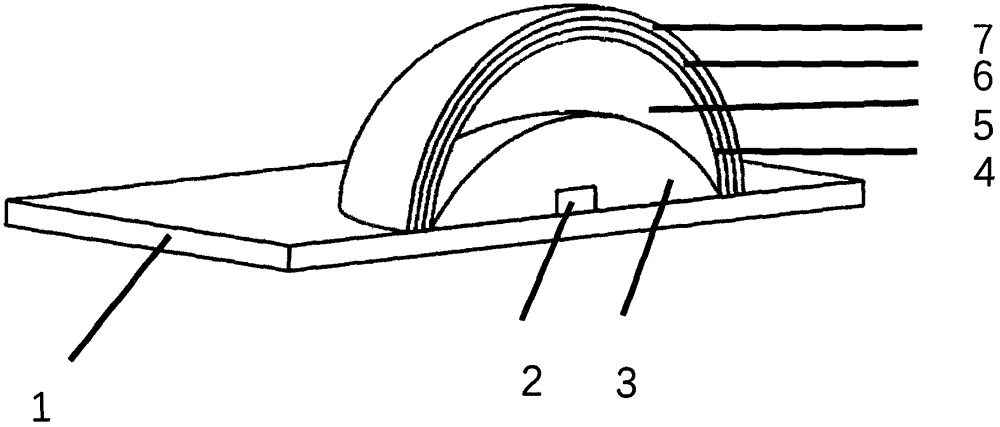

[0016] Such as figure 1 As shown, an LED packaging structure includes a substrate 1, an LED chip 2 arranged on the substrate 1, a filling colloid 3 for sealing the LED chip 2, a phosphor layer 6, a first colloid layer 4 and a second colloid Layer 7; the first colloidal layer 4 is coated outside the filling colloid 3, and forms a cavity 5 with the filling colloid 3; the middle of the cavity 5 is thick and the edge is thin; the phosphor layer 6 is coated on the first colloidal layer 4; the second colloidal layer 7 is coated on the phosphor layer 6.

Embodiment 2

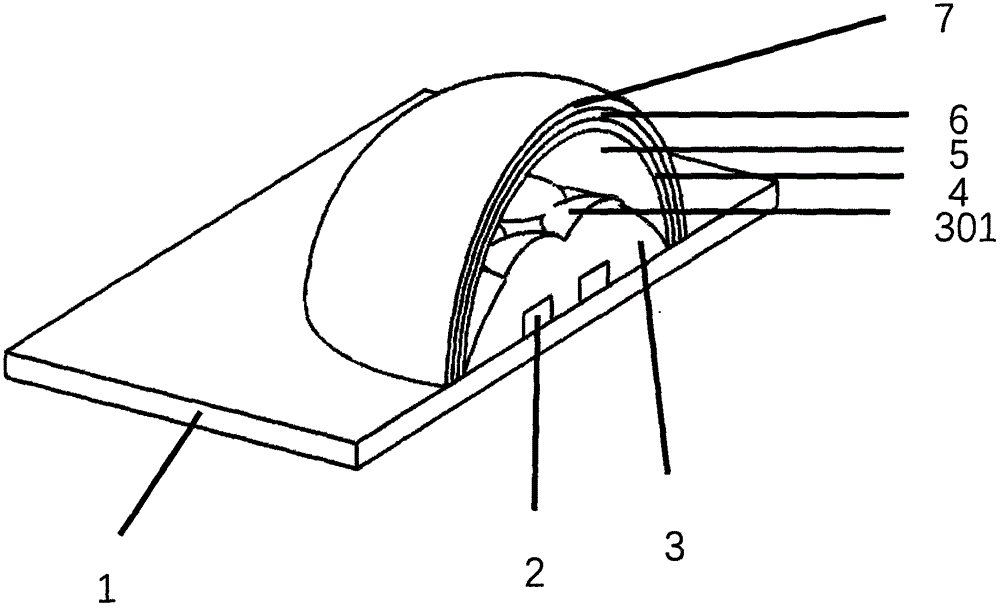

[0018] Such as figure 2 As shown, an LED packaging structure includes a substrate 1, an LED chip 2 arranged on the substrate 1, a filling colloid 3 for sealing the LED chip 2, a phosphor layer 6, a first colloid layer 4 and a second colloid Layer 7; the first colloidal layer 4 is coated on the outside of the filling colloid 3, and forms a cavity 5 with the filling colloid 3; the phosphor layer 6 is coated on the first colloidal layer 4 above; the second colloidal layer 7 is coated on the phosphor layer 6 . The number of the LED chips 2 is greater than 1, and the surface of the filling colloid 3 has protrusions 301 , and each protrusion 301 corresponds to one LED chip 2 .

[0019] The light emitted by the LED chip 2 enters the filling colloid 3 and is refracted at the interface between the filling colloid 3 and the cavity 5. The intensity of the blue light is redistributed and reaches the phosphor layer 6 through the first colloid layer 4, and part of the blue light passes th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com