Miniaturized preassembled substation for towns

A technology for prefabricated substations and towns, which is applied to substations installed on poles, etc., which can solve the problems of large area occupied by prefabricated substations, inconvenient operation and maintenance, and many types of components, so as to improve the level of operation and maintenance , Improving the construction safety level and improving the effect of personal safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

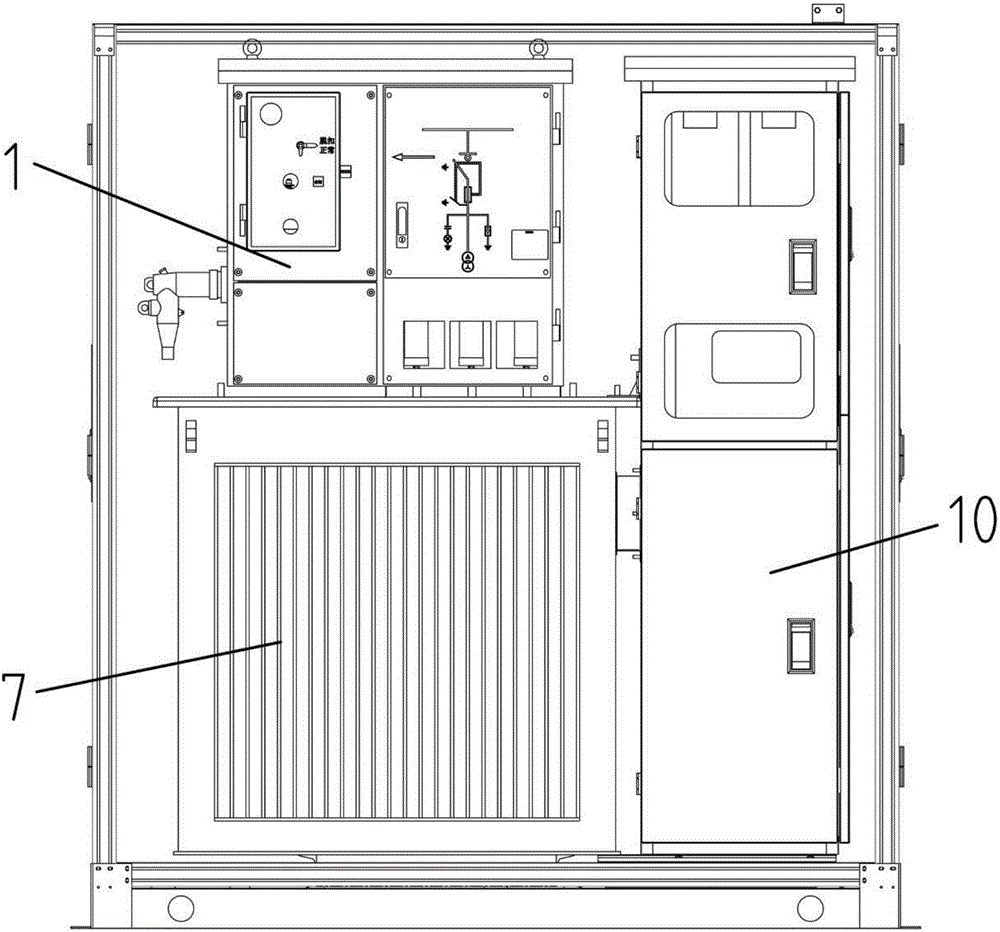

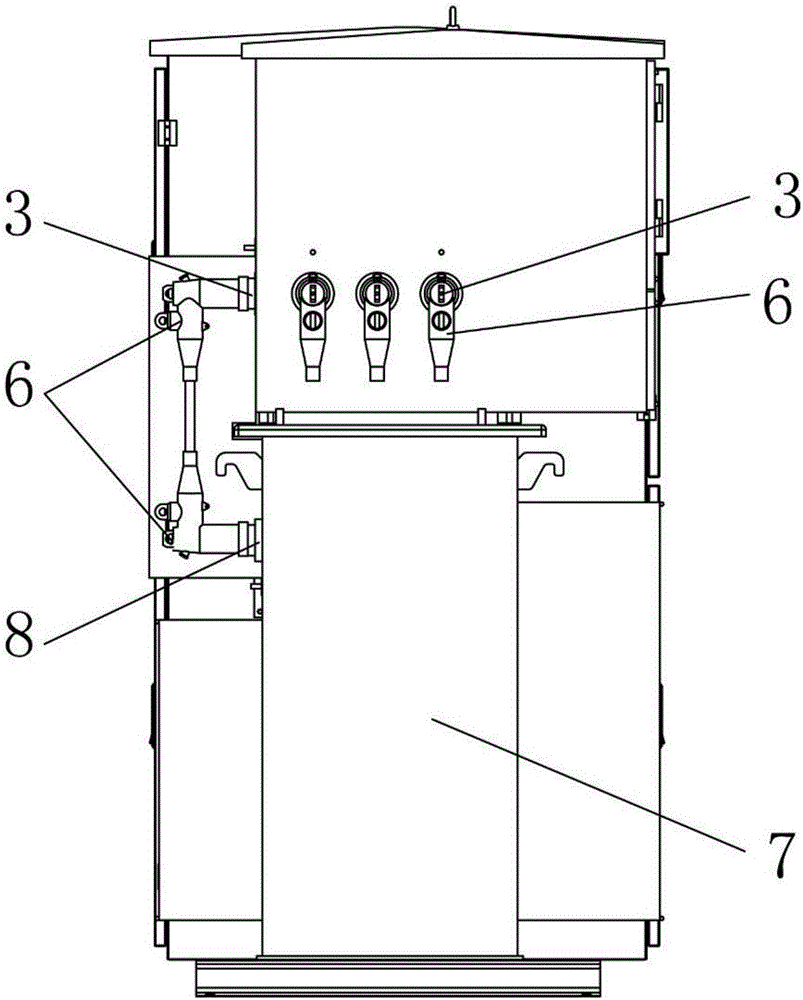

[0051] like Figure 11 As shown, according to the present invention, the urban miniaturized prefabricated substation is installed between two utility poles.

[0052] The urban miniaturized prefabricated substation of the present invention is installed between utility poles 28, and the horizontal arm 29 is fixed approximately 2 to 2.5 meters away from the ground level. The type substation is hoisted as a whole, and is located on the installation cross arm 29, and the transformer and the channel steel at the bottom of the integrated intelligent distribution box are installed and fixed on the installation cross arm 29 through fasteners. The left side of the high-voltage switch cabinet is provided with a high-voltage incoming line bushing 2, which is connected with a high-voltage incoming line cable 5 and a high-voltage incoming line cable joint 4. The post-mounted installation of the miniaturized prefabricated substation for urban use is completed.

[0053] The overall working ...

Embodiment 2

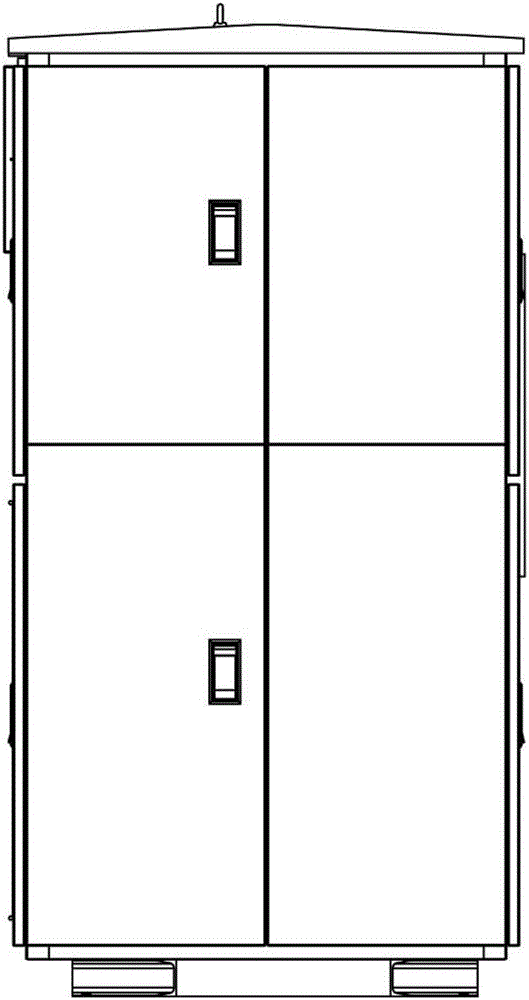

[0074] like Figure 7-9 As shown, the structural schematic diagram of the frame shell in the urban miniaturized prefabricated substation of the present invention.

[0075]When the substation is installed on the ground, the substation is installed inside the frame shell 23. The frame shell includes an aluminum profile frame 24, a top plate 25 and a stainless steel door 26. The aluminum profile frame can be installed in a factory or on site, with great flexibility. The strength meets the IK anti-collision level required by the State Grid. It is light in weight, convenient for hoisting and transportation, and has high aesthetics. The plate is made of 201 stainless steel, which can achieve outdoor anti-rust effect. , The sealing level reaches IP23D, and it can achieve good heat dissipation effect without additional exhaust fan. According to user requirements, LED display screen 27 can be optionally installed on the back of the frame shell (such as Figure 10 Shown), can play the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com