Methods for producing alkaline earth carbonates

A carbonate, alkaline earth technology, applied in magnesium carbonate, chemical instruments and methods, calcium carbonate/strontium/barium, etc., can solve the problems of unclear industrial scale, dependence on seeds and limited industrial applications, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

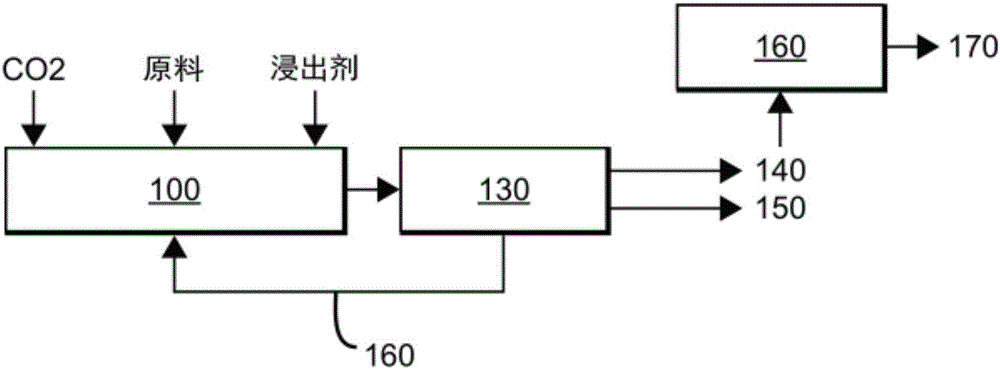

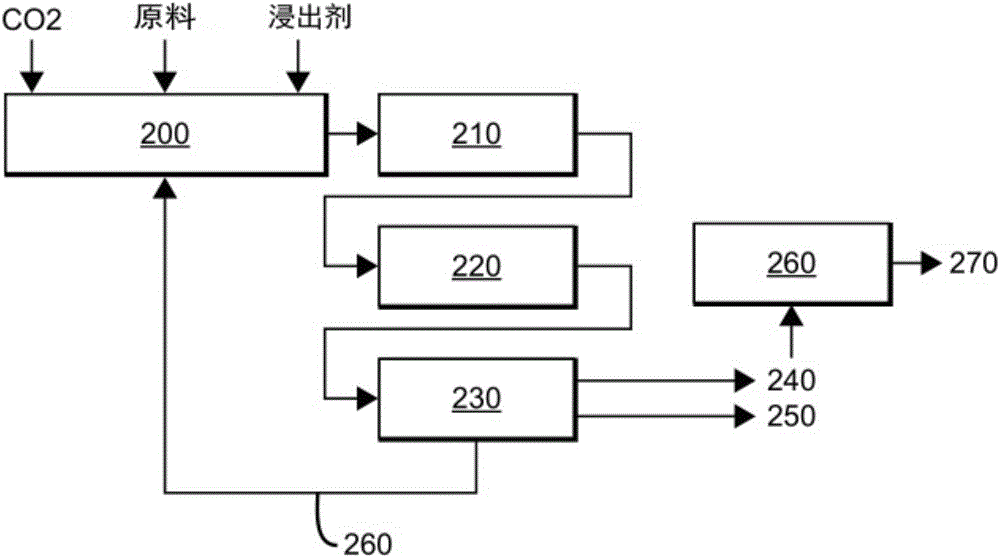

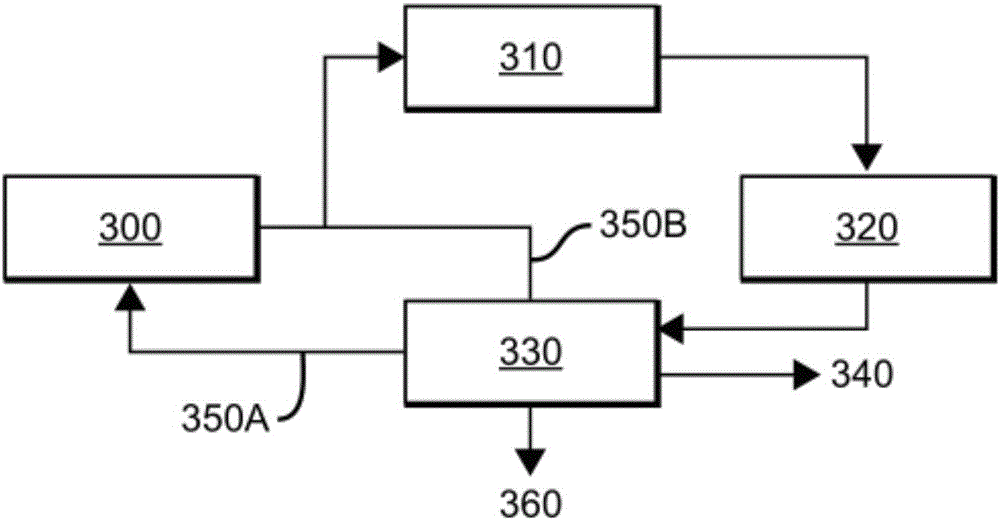

Method used

Image

Examples

Embodiment

[0126] Raw Materials and Methods

[0127] In these experiments, two basic oxygen furnace (BOF) slags were used as feedstock sources of extractable calcium oxide / hydroxide. One sample consisted of raw fines from the U.S. Steel Lake Erie Works in Canada, while the other was a sample from a waste stream produced at the slag recycling plant of Ruukki Metals Raahe Works in Finland. The composition of these slags analyzed by XRF is provided in Figure 14 in the table shown in . As the materials had been stored in the open air, they were calcined at 900°C for 3 hours before extraction to reduce any material that might have been carbonated by environmental factors.

[0128] U.S. steel slag is directly screened to the desired size fraction, while Ruukki slag is first ground to a smaller size fraction and then screened to the final desired size fraction. In this experiment, a specified amount of slag was mixed with an amount of ammonium chloride leachant solution of known concentra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com