Improved tobacco drying room

A flue-cured tobacco room and flue-cured tobacco technology, which is applied in the field of flue-cured tobacco room, can solve the problems of insufficient fuel combustion, affecting the quality of tobacco leaves, harm to humans and animals, etc., and achieve the effects of full combustion, avoiding burning wires and saving energy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

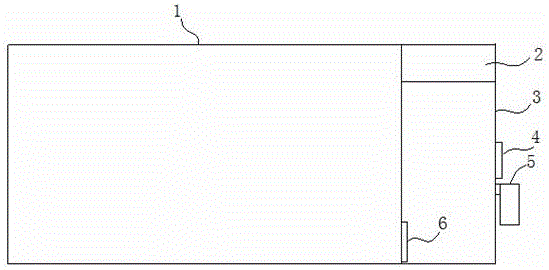

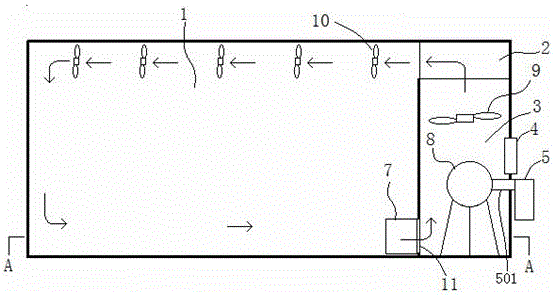

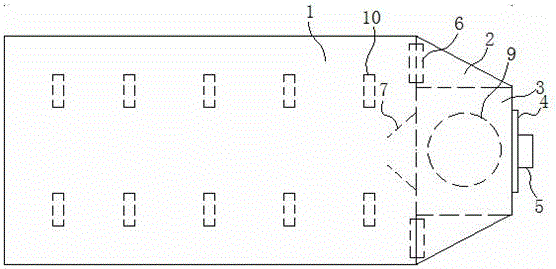

[0025] See Figure 1 to Figure 7 , the improved flue-cured tobacco room provided by the present invention comprises a flue-cured tobacco area 1 and a heating area 3 isolated from the flue-cured tobacco area 1, and the upper and lower circulating air ducts are arranged between the heating area 3 and the flue-cured tobacco area 1 2 communicates with the lower circulation outlet 11, the heating zone 3 is provided with heat exchange heating equipment and air intake device 4, and a heat exchange fan 9 is provided between the heat exchange heating equipment and the upper circulation air duct 2, and the lower circulation The tuyere 11 is provided with an elastic moisture discharge door 7, and the lower part of the flue-cured tobacco area 1 is provided with louver moisture discharge ports 6 on both sides in front of the lower part. 10, the air intake device 4 is controlled to be opened and closed by the humidity sensor located in the flue-cured tobacco area; the heat exchange heating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com