Coagulation kettle and coagulation device for rubber polymer and coagulation method for rubber polymer solution

A technology of rubber polymer and coagulation method, which is applied in the direction of fractional distillation to achieve the effect of prolonging the residence time and enhancing the solvent removal effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0081] This example is used to illustrate the coagulation method of the rubber polymer solution of the present invention.

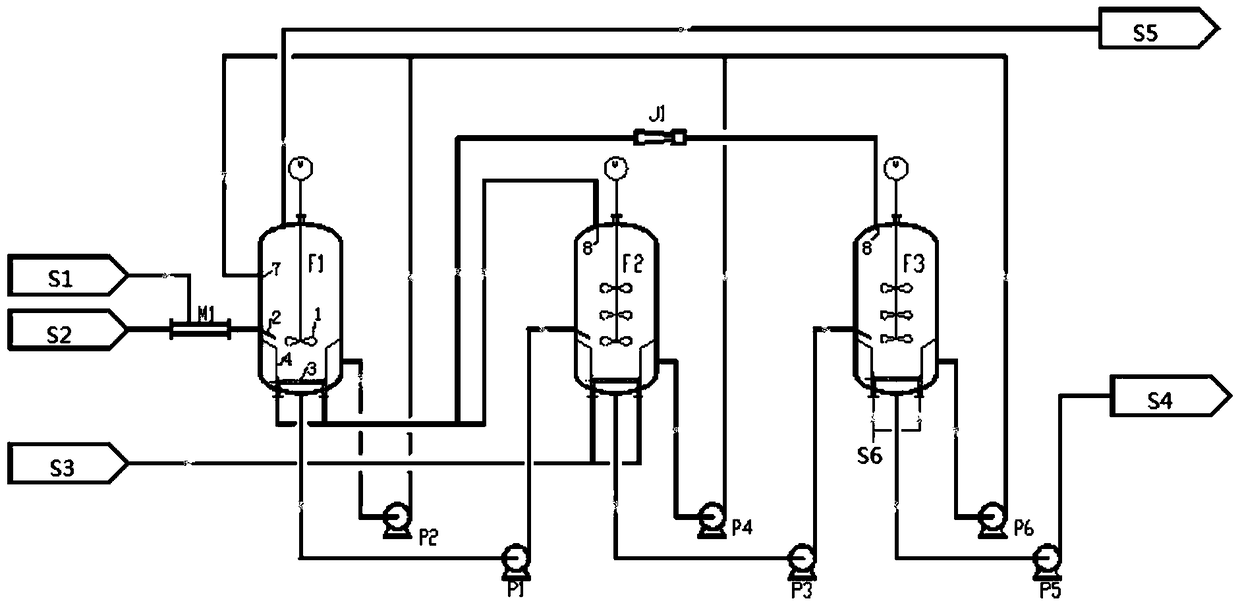

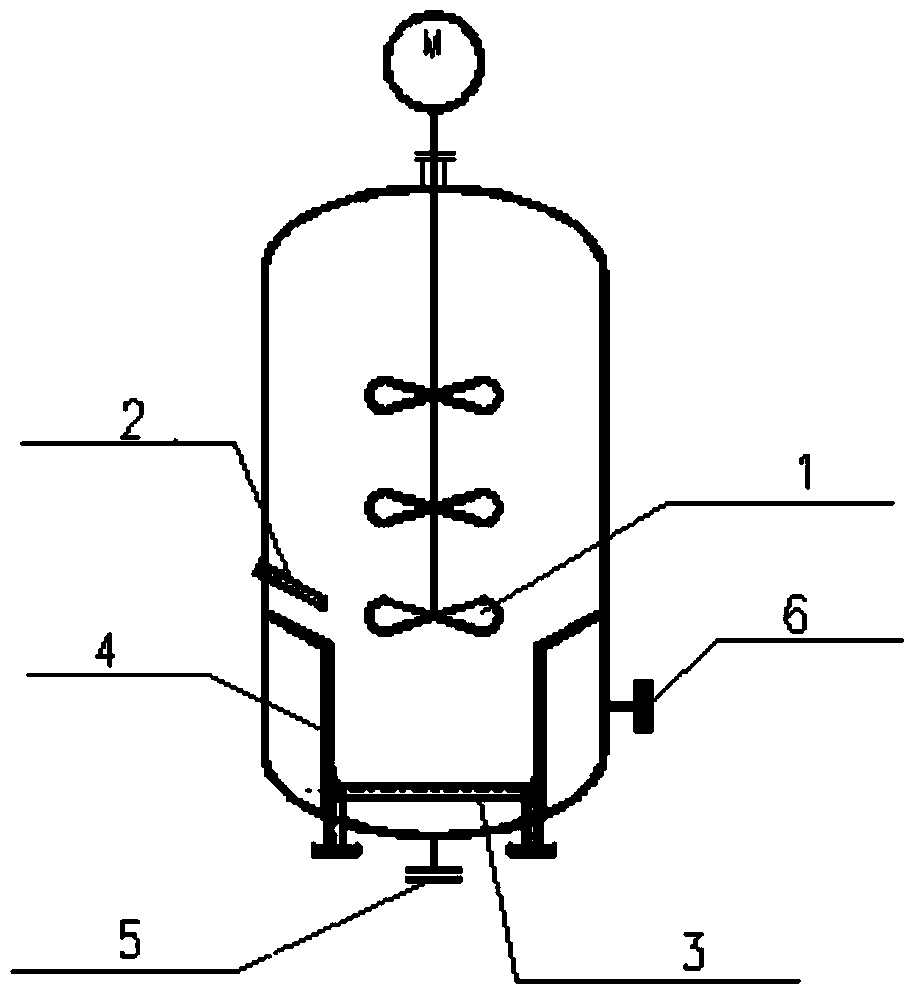

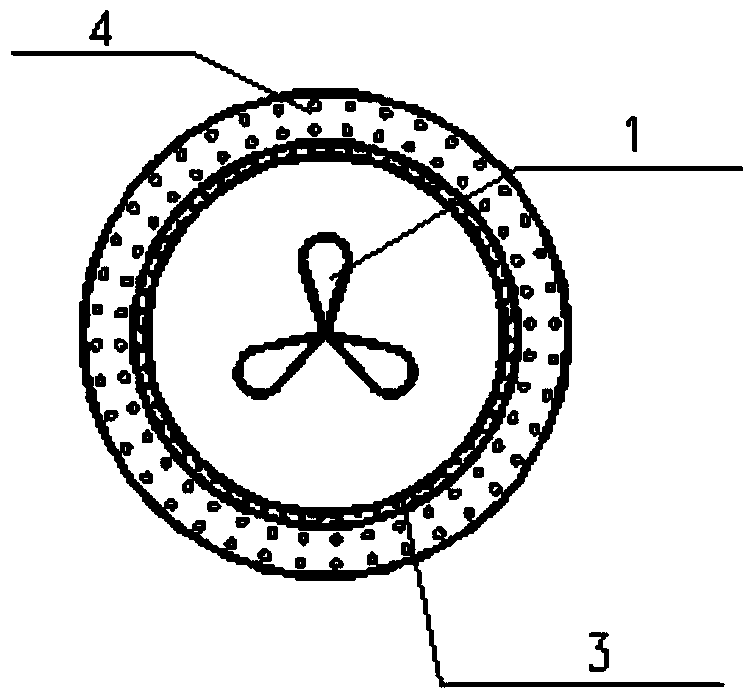

[0082]Mix the rubber polymer solution at a flow rate of 5000kg / h with hot water (at a temperature of 90°C and a flow rate of 40000kg / h) and then send it into the spray pipe at a flow rate of 45000kg / h figure 1 In the first condensing still F1, keep the bottom of the still by the steam flow rate of steam feeding device 3 is 450kg / h (from the steam that the still top of the second condensing still F2 and the 3rd condensing still F3 discharge), the still top water inlet 7 The water flow rate is 5000kg / h;

[0083] Among them, the operating pressure of the first coagulation tank F1 is gauge pressure 0.02-0.03MPa, the temperature is 88-92°C, and the residence time of colloidal water is 49.1min;

[0084] The operating pressure of the second coagulation tank F2 is gauge pressure 0.06-0.09MPa, the temperature is 103-110°C, the residence time of colloidal water is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com