Technique and equipment for fabricating plastic sheet material produced from molding laminar die in low pressure

A sheet molding compound, low-pressure molding technology, applied in the field of low-pressure molding sheet molding compound sheet production equipment, can solve the problems of clogging the scraper and PE film, uneven distribution, and affecting the effect of resin paste on fiber impregnation, etc., to achieve Improved temperature and pressure conditions, overcoming high molding temperature and pressure, and reducing requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

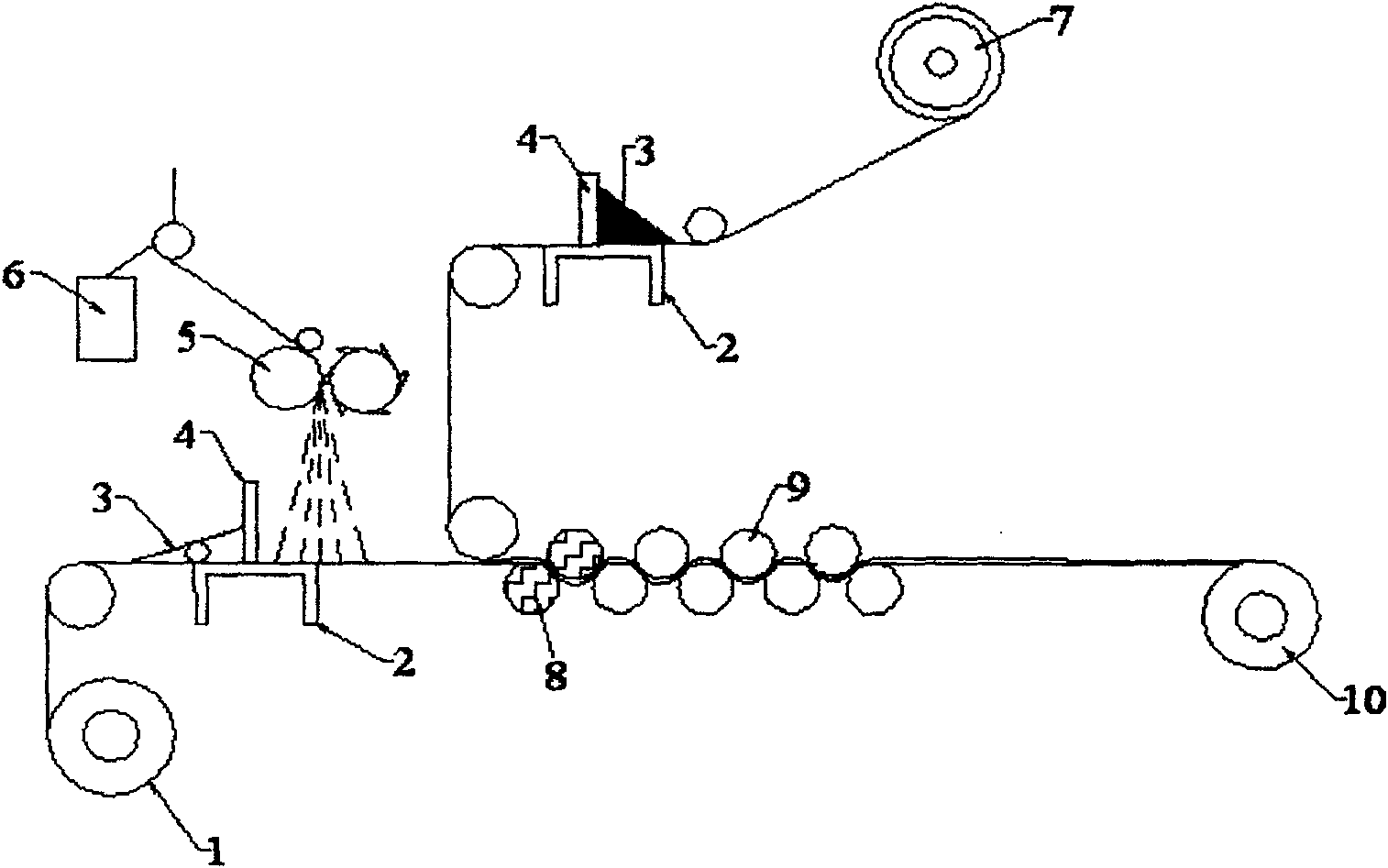

[0014] The present invention will be further described below in conjunction with the embodiments and accompanying drawings.

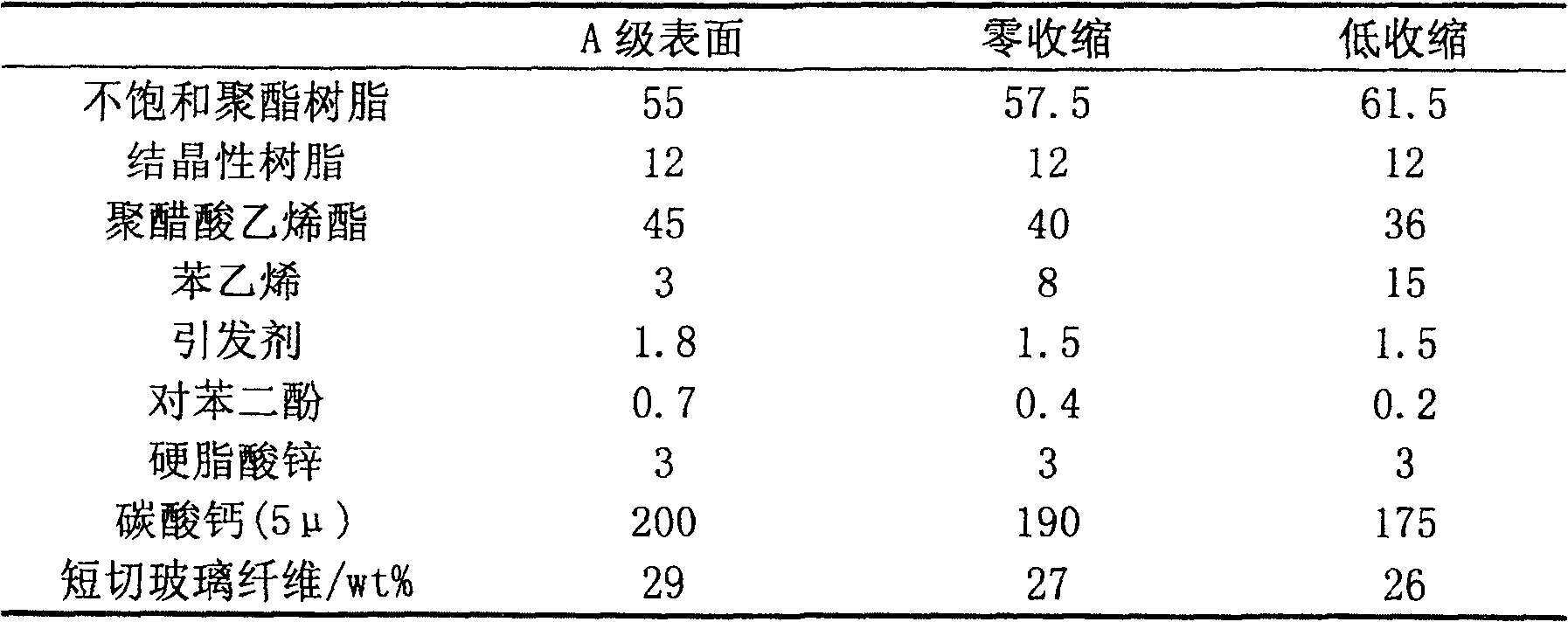

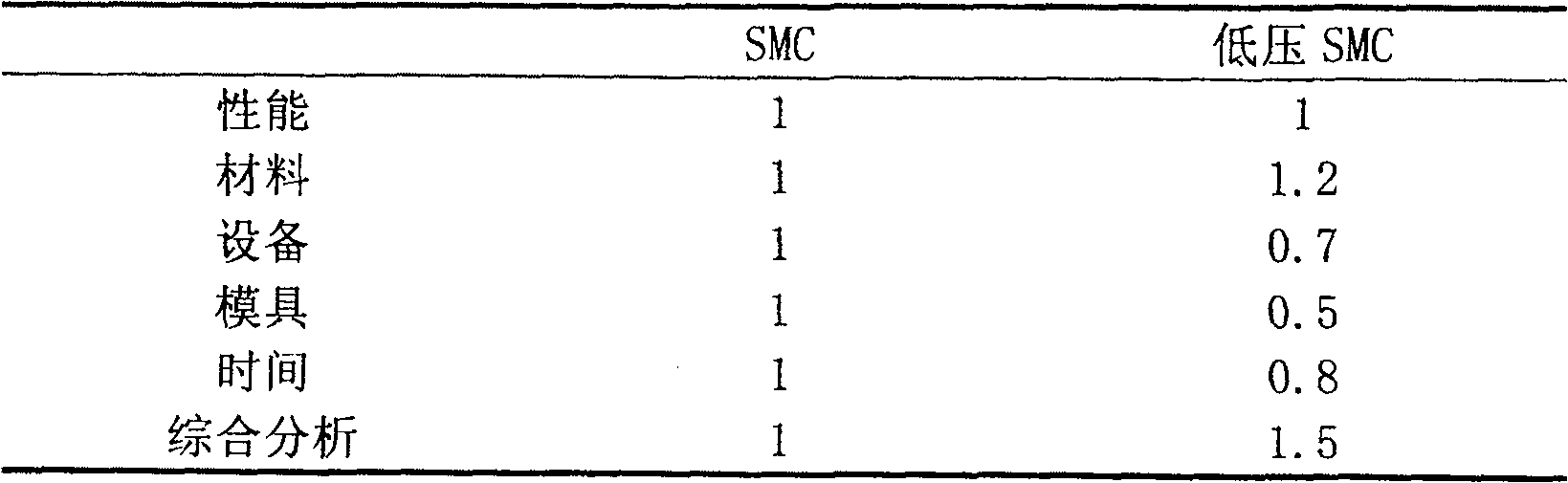

[0015] 1. Low pressure forming sheet molding compound sheet

[0016] Prepared from the following raw materials in parts by mass:

[0017] 50-80 parts of unsaturated polyester resin, 5-20 parts of crystalline resin, 20-50 parts of low shrinkage additive, 0.8-1.2 parts of initiator, 0.5-1 part of polymerization inhibitor, 2-4 parts of internal mold release agent, 80-200 parts of filler, chopped glass fiber accounts for 20%-35% of the total mass of the sheet.

[0018] Among the above-mentioned raw materials, the unsaturated polyester resin can adopt No. 191 unsaturated polyester resin. The crystalline resin can be a crystalline resin with a melting point of 50-80°C, and its function is to physically thicken. The low-shrinkage additive can use thermoplastic resins such as polystyrene and polyvinyl acetate, and its function is to reduce shrinkage. The in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com