Spherical gel particle as well as preparation method and application thereof

A gel particle and spherical technology, applied in chemical instruments and methods, drilling compositions, etc., can solve problems such as weak gelation ability and low underground compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The invention provides a preparation method of spherical gel particles, comprising the following steps:

[0033] (1) mixing acrylic acid, water and alkali, and carrying out neutralization reaction to obtain a mixed solution; the degree of neutralization of acrylic acid in the mixed solution is 55-85%;

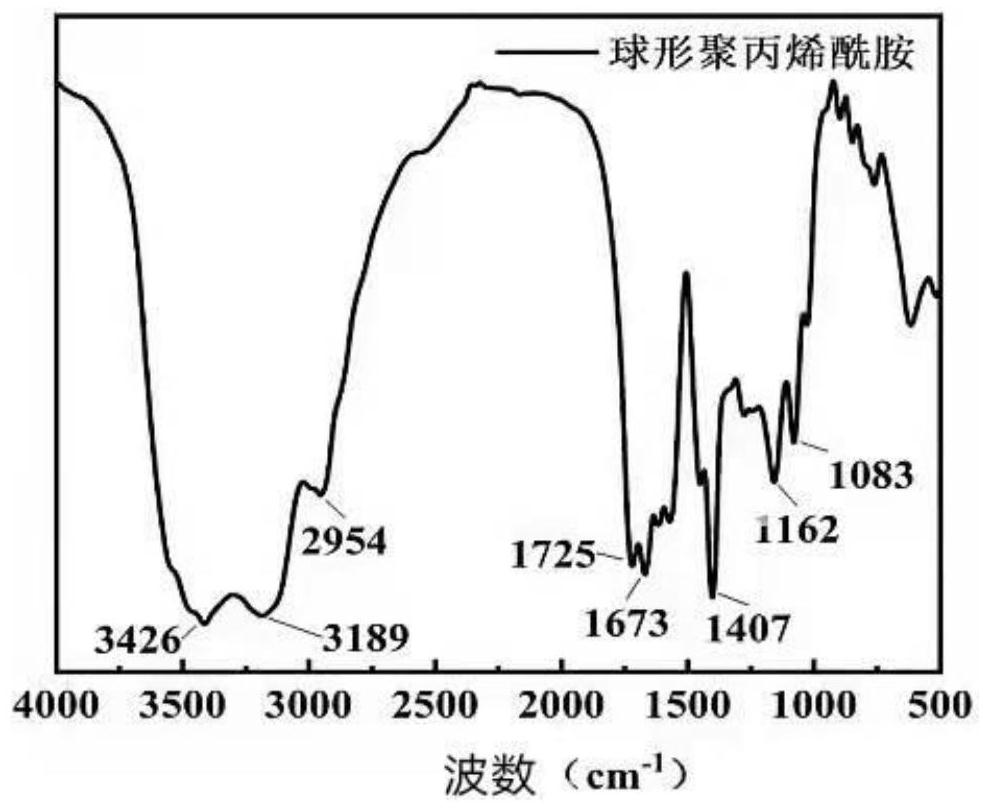

[0034] (2) mixing the mixed solution obtained in the step (1) with methacrylic acid-β-hydroxyethyl ester, acrylamide, potassium persulfate and aluminum nitrate to obtain a precursor solution;

[0035] (3) adding the precursor obtained in the step (2) dropwise to the silicone oil to carry out free radical polymerization to obtain spherical gel particles;

[0036] The temperature of the silicone oil is 80-100°C.

[0037] In the present invention, unless otherwise specified, the raw materials used are conventional commercially available products in the field.

[0038] In the present invention, acrylic acid, water and alkali are mixed, and a neutralization reaction is carr...

Embodiment 1

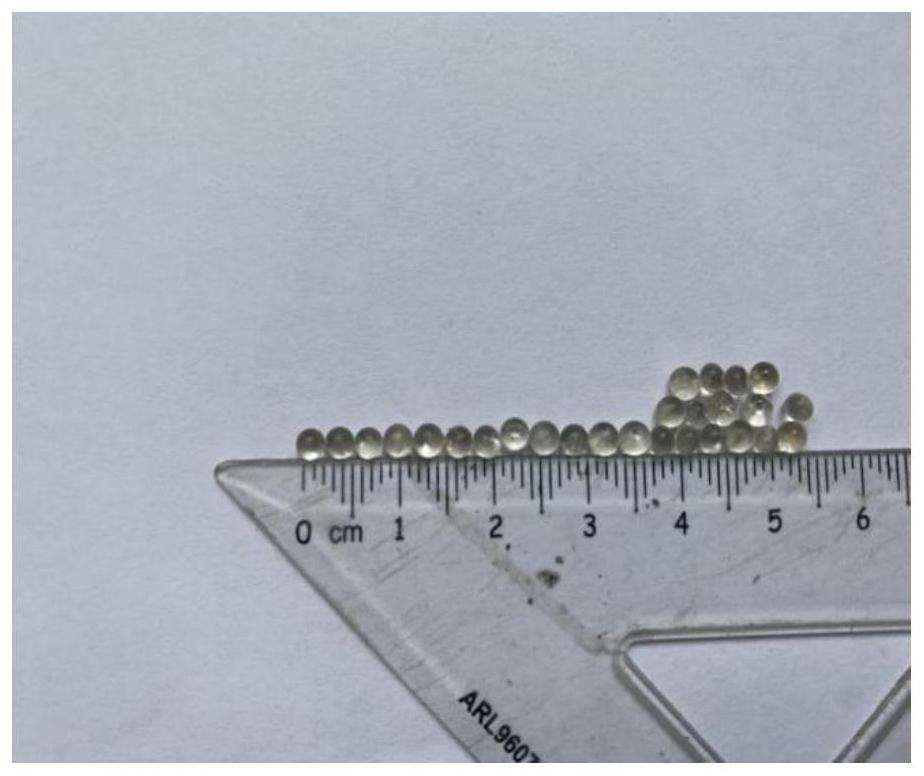

[0063] A kind of preparation method of spherical gel particles

[0064] (1) under the condition of stirring, add 3.6g acrylic acid and 4g water to the beaker of 50mL, then slowly add 1.6g sodium hydroxide, carry out neutralization reaction, obtain the mixed solution that the neutralization degree of acrylic acid is 80%; The mass ratio of acrylic acid and water is 3.6:4;

[0065] (2) 0.517g of methacrylic acid-β-hydroxyethyl ester and 2.1g of acrylamide were successively added to the mixed solution obtained in the step (1), and then, under stirring conditions, 0.5% of permeate was added successively. The potassium sulfate aqueous solution (containing 0.057g potassium persulfate) and the aluminum nitrate aqueous solution (containing 0.057g aluminum nitrate) with a mass concentration of 0.5% are mixed to obtain a precursor solution;

[0066] The mass ratio of acrylic acid in the step (2) and acrylamide in the step (2) is 1.2:0.7;

[0067] In the step (2), the mass fraction of m...

Embodiment 2

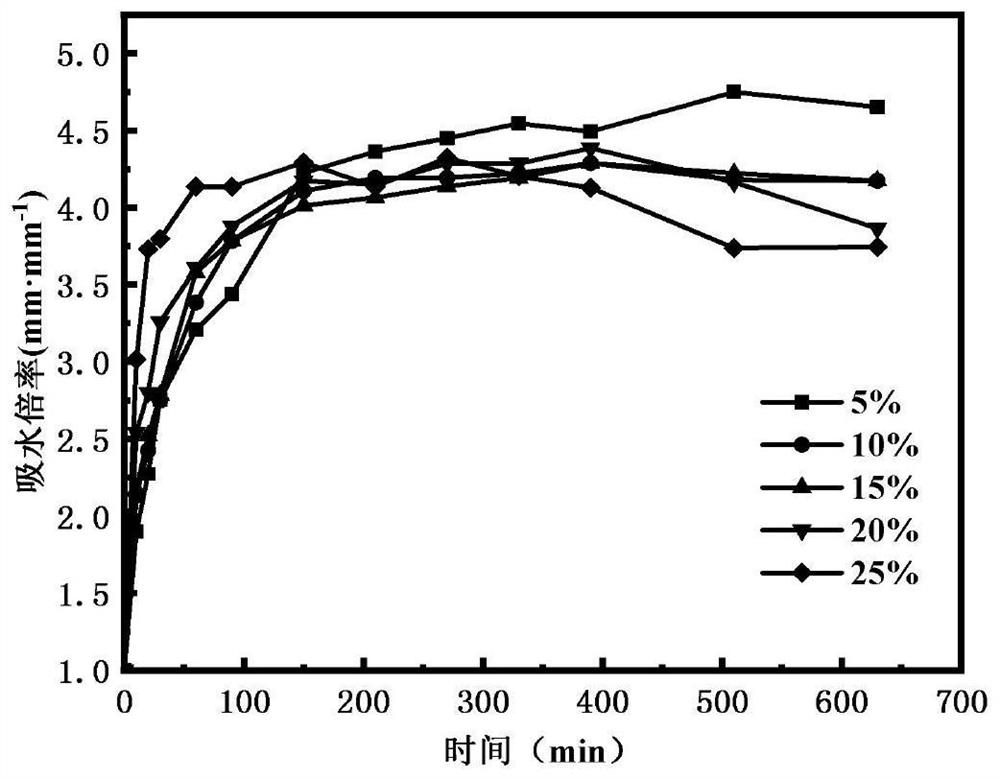

[0071] Spherical gel particles were prepared according to the method of Example 1

[0072] The difference from Example 1 is that in the step (2), the mass of β-hydroxyethyl methacrylate is 1.035 g, and the mass fraction of β-hydroxyethyl methacrylate in the precursor solution is 10%. .

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com