Rotary table mechanism mated with three-axis vertical type engraving and milling high-speed machine

A technology of turntable mechanism and high-speed machine, which is applied in the direction of metal processing machinery parts, clamping, support, etc. It can solve the problems that the surface finish of the product cannot reach the mirror effect, the positioning accuracy is difficult to grasp, and the product cannot realize self-rotation, etc., so as to improve the processing efficiency. The effect of production efficiency, maximum practical value, saving processing time and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

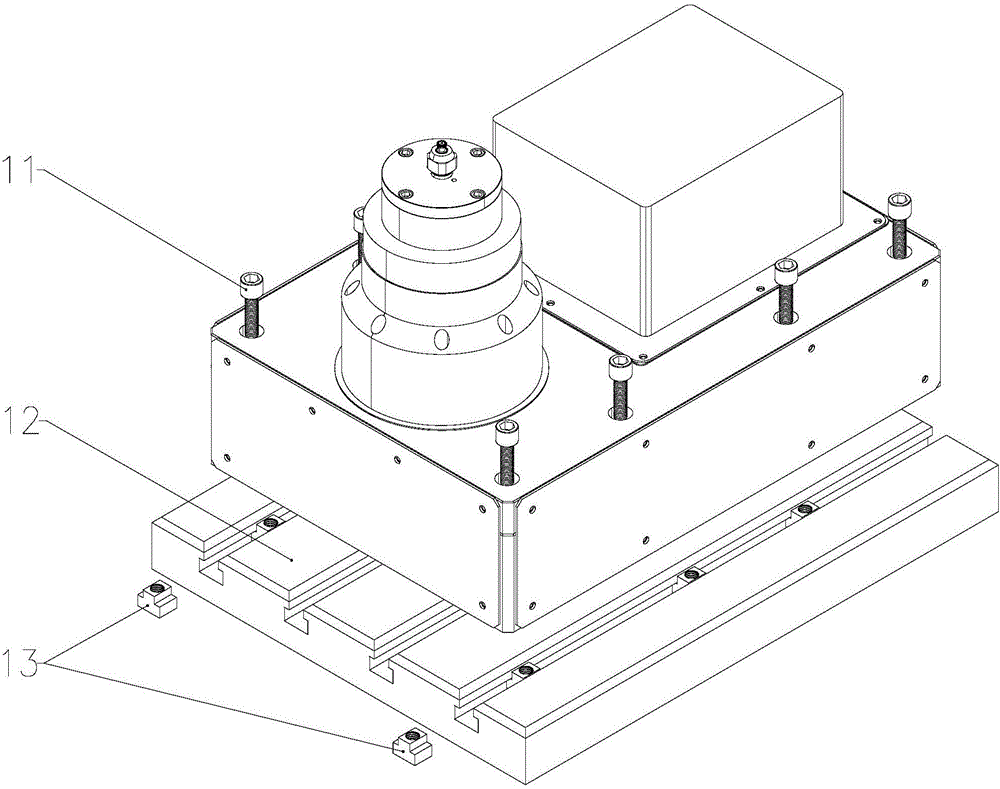

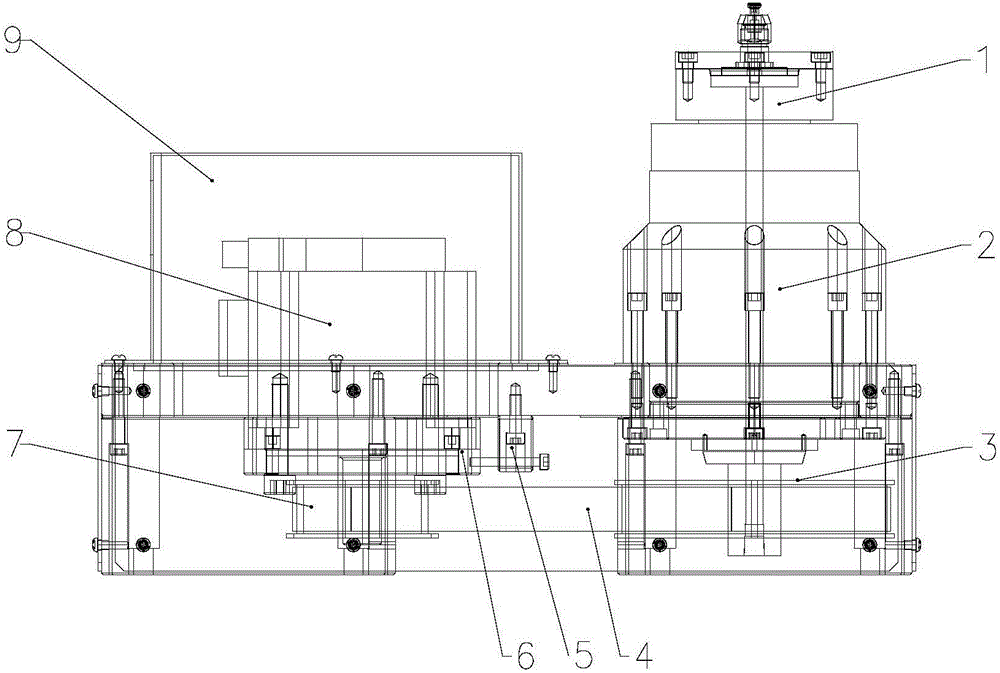

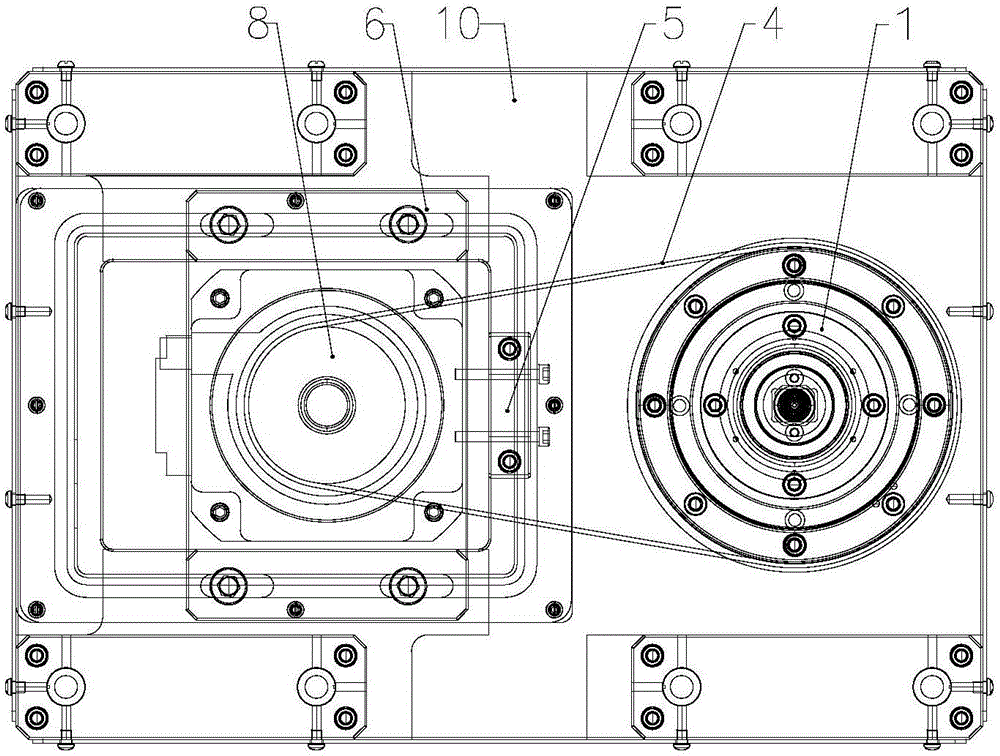

[0014] Such as figure 1 , 2 , 3, a turntable mechanism matched with a three-axis vertical engraving and milling high-speed machine, including a bracket, a waterproof cover 9, a drive motor 8, a motor support plate 6, a driving wheel 7, a synchronous belt 4, and a synchronous belt tensioner Fixed block 5, driven wheel 3, turntable 2, product fixture 1. A base is installed below the support, and the base is provided with a cover plate 10 that seals the opening on the base. The front end of the drive motor 8 is installed and fastened on the motor support pallet 6, and the motor support pallet 6 is connected with the cover. plate 10 is connected, and the timing belt tensioning block 5 is fixed under the cover plate 10. For the convenience of installation and pre-tightening of the timing belt, the motor support plate 6 is provided with a waist-sha...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap