Device for fixing tail end of toilet roll

A technology for toilet paper rolls and paper rolls, which is applied in the field of devices at the tail end, can solve the problems of difficulty in accurately controlling the size of the pressing force, loose paper rolls, and many production processes, so as to improve production efficiency, avoid damage to paper rolls, and reduce the number of processes. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

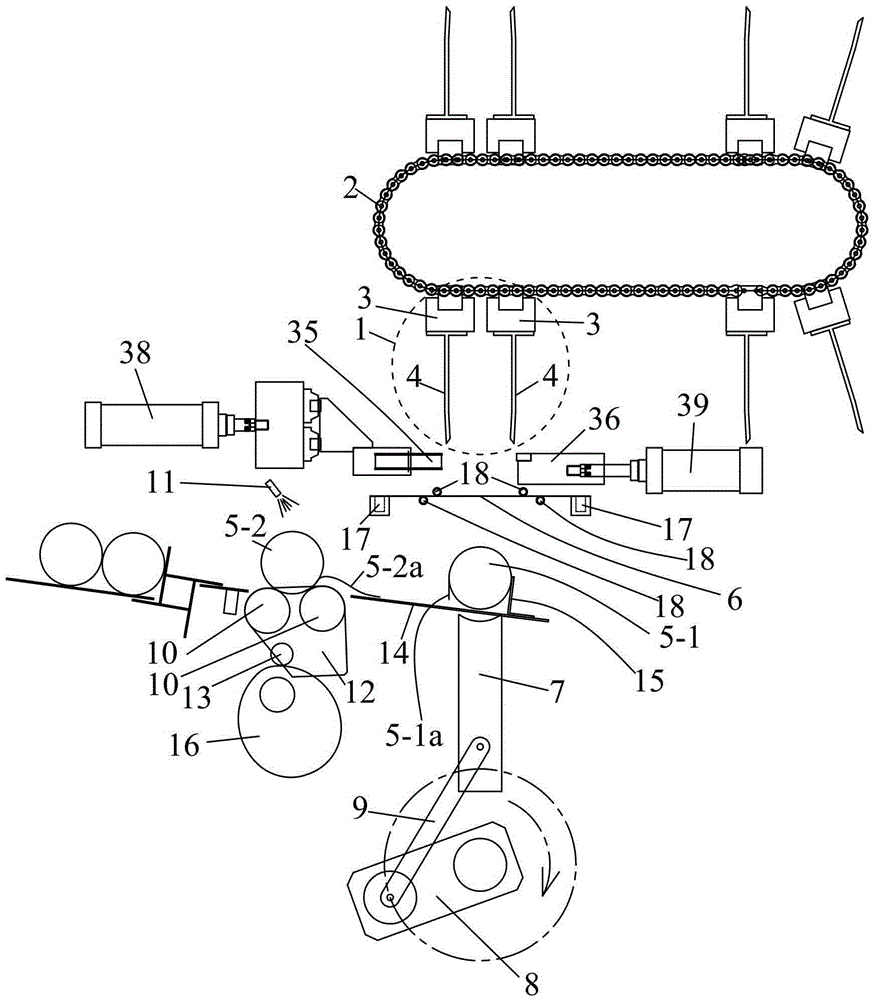

[0031] see figure 1 According to the present invention, a device for fixing the end of a toilet paper roll is mainly composed of a handle, a paper roll conveying mechanism, a paper laying mechanism, a paper roll pushing mechanism, and a rolling mechanism. The details are described below respectively.

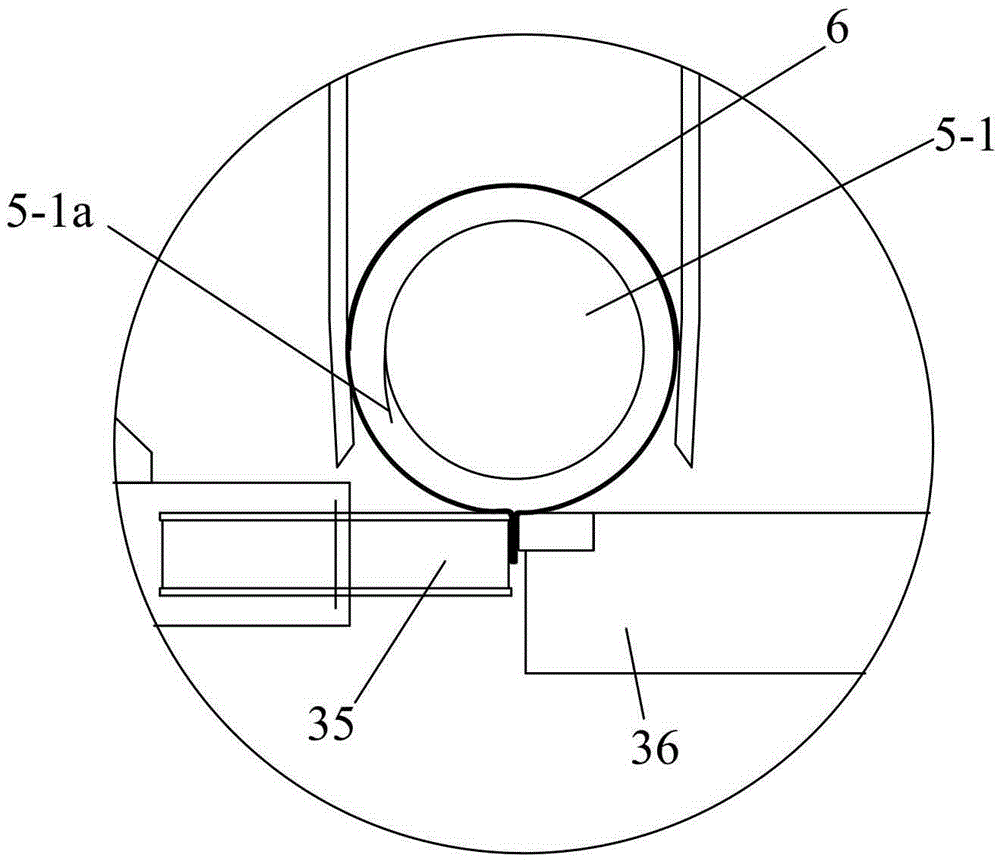

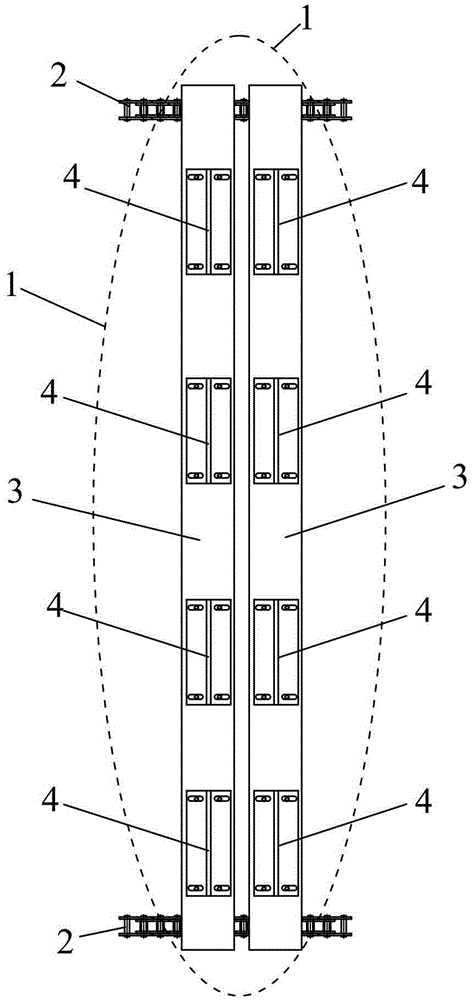

[0032] like figure 1 As shown, the present embodiment is provided with a plurality of grippers 1 , and the plurality of grippers 1 are driven by the transmission chain 2 to circulate. The structure of each gripper 1 is as follows figure 1 and combine figure 2 As shown, it includes two parallel struts 3, and the two struts 3 are respectively fixed with a plurality of splints 4, and the splints 4 on the two struts 3 are opposite to each other, and clamp the same paper roll together. The two struts 3 are fixed between the two parallel transmission chains 2, and the two transmission chains 2 together drive the two struts 3 to circulate, and then drive the gripper 1 to circulate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com