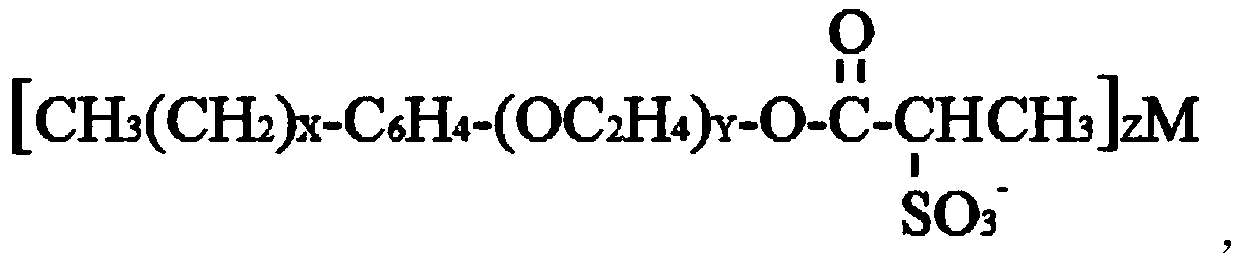

A kind of hydrothermal cracking catalytic viscosity reducer and preparation method thereof

A technology for catalytic viscosity reduction and hydrothermal cracking, applied in chemical instruments and methods, preparation of sulfonic acid, preparation of carboxylic acid halide, etc., can solve the problems of poor salt resistance, high service temperature, poor dispersion and penetration performance, etc. To achieve the effect of simple preparation process, strong universality and salt tolerance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

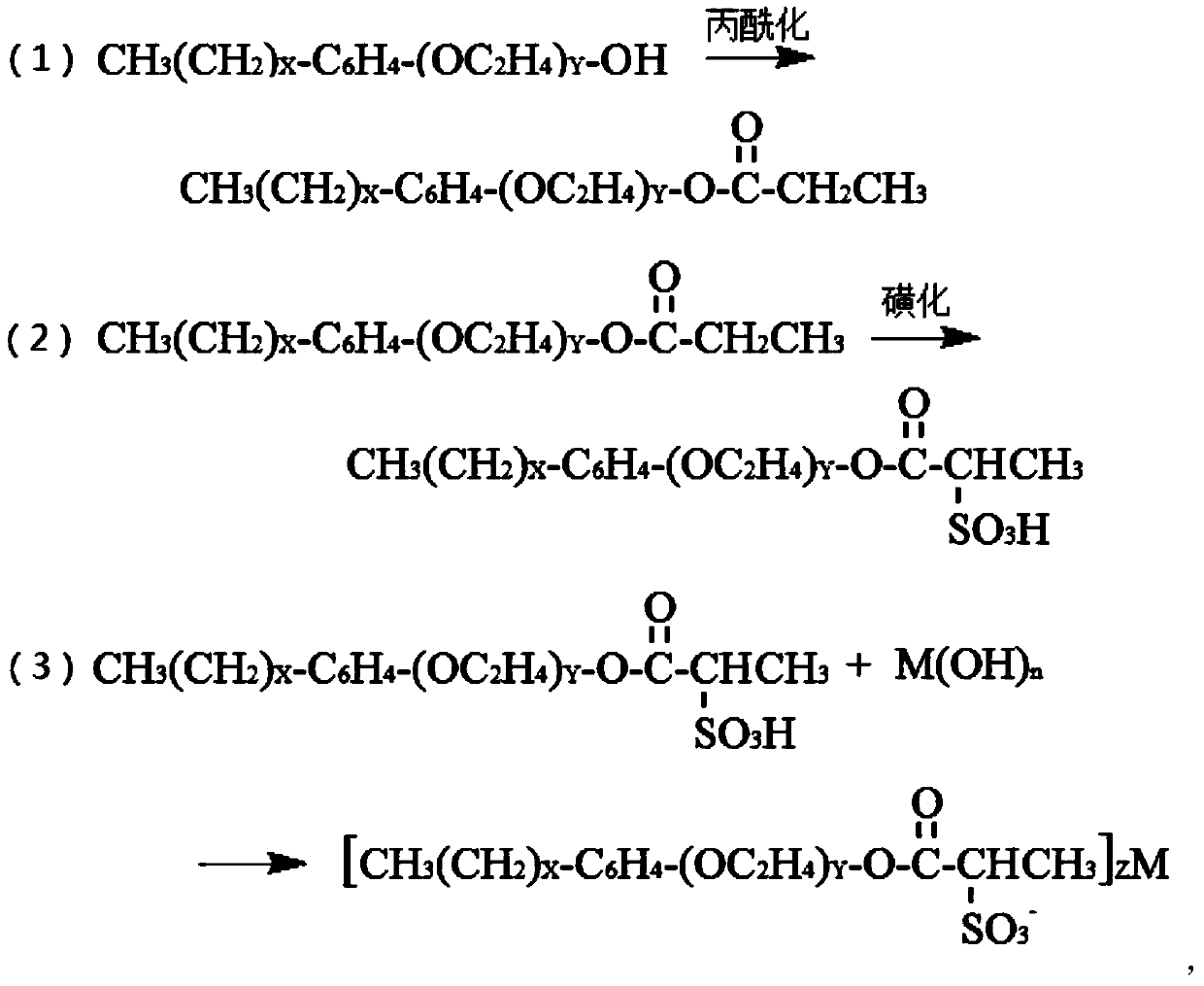

Method used

Image

Examples

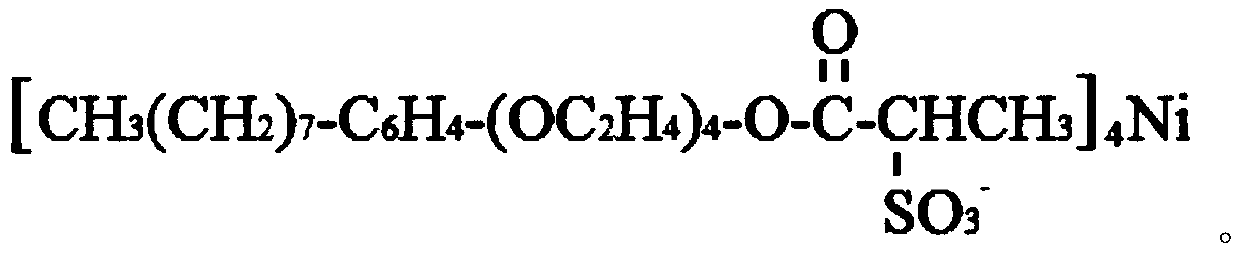

Embodiment 1

[0030] Add 0.1 mol of industrial grade octylphenol polyoxyethylene ether OP-4 into the reactor with stirrer and thermometer, heat and stir at 60°C for 1h, then add 0.15mol of propionyl chloride into the reactor, heat up to 90°C, After reacting for 1h, cool to room temperature to obtain octylphenol polyoxyethylene ether propionate; then add 0.6mol of ethylene dichloride as a reaction solvent in the reactor containing octylphenol polyoxyethylene ether propionate, and react The reactor was transferred to an ice-water bath, and reacted with 0.12mol chlorosulfonic acid for sulfonation, and the reaction time was 0.5h. After the sulfonation was completed, the reactor was transferred to an oil bath and heated to 80°C for 1h to obtain octylphenol polymer Oxyethylene ether propionate sulfonic acid; finally, add 0.05 mol of nickel hydroxide to the reactor containing octylphenol polyoxyethylene ether propionate sulfonic acid, heat up to 120°C and stir for 1 hour, and let stand after the re...

Embodiment 2

[0035] Add 0.1 mol of technical grade nonylphenol polyoxyethylene ether NP-7 into the reactor with stirrer and thermometer, heat and stir at 70°C for 1h, then add 0.12mol of propionyl chloride into the reactor, heat up to 100°C, Cool to room temperature after reacting for 2h to obtain nonylphenol polyoxyethylene ether propionate; then add 0.5mol of dichloroethane as the reaction solvent in the reactor containing nonylphenol polyoxyethylene ether propionate, and react The reactor was transferred to an ice-water bath, and reacted with 0.14mol chlorosulfonic acid for sulfonation, and the reaction time was 0.5h. After the sulfonation was completed, the reactor was transferred to an oil bath and heated to 90°C for 1h to obtain nonylphenol polymer Oxyethylene ether propionate sulfonic acid; finally, add 0.05 mol of ferric hydroxide to the reactor containing nonylphenol polyoxyethylene ether propionate sulfonic acid, heat and stir at 110°C for 2 hours, and let stand after the reaction...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com