Method and application of in-situ electrochemical growth of nano-carbide-based electrocatalytic film on the surface of self-supporting carbon substrate

An in-situ electrochemical, carbon-based technology, applied in the fields of nanotechnology, nanotechnology, nanotechnology for materials and surface science, can solve problems such as being unsuitable for large-scale engineering applications, and achieve excellent electrocatalytic activity, Excellent electrochemical stability, low reaction temperature effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

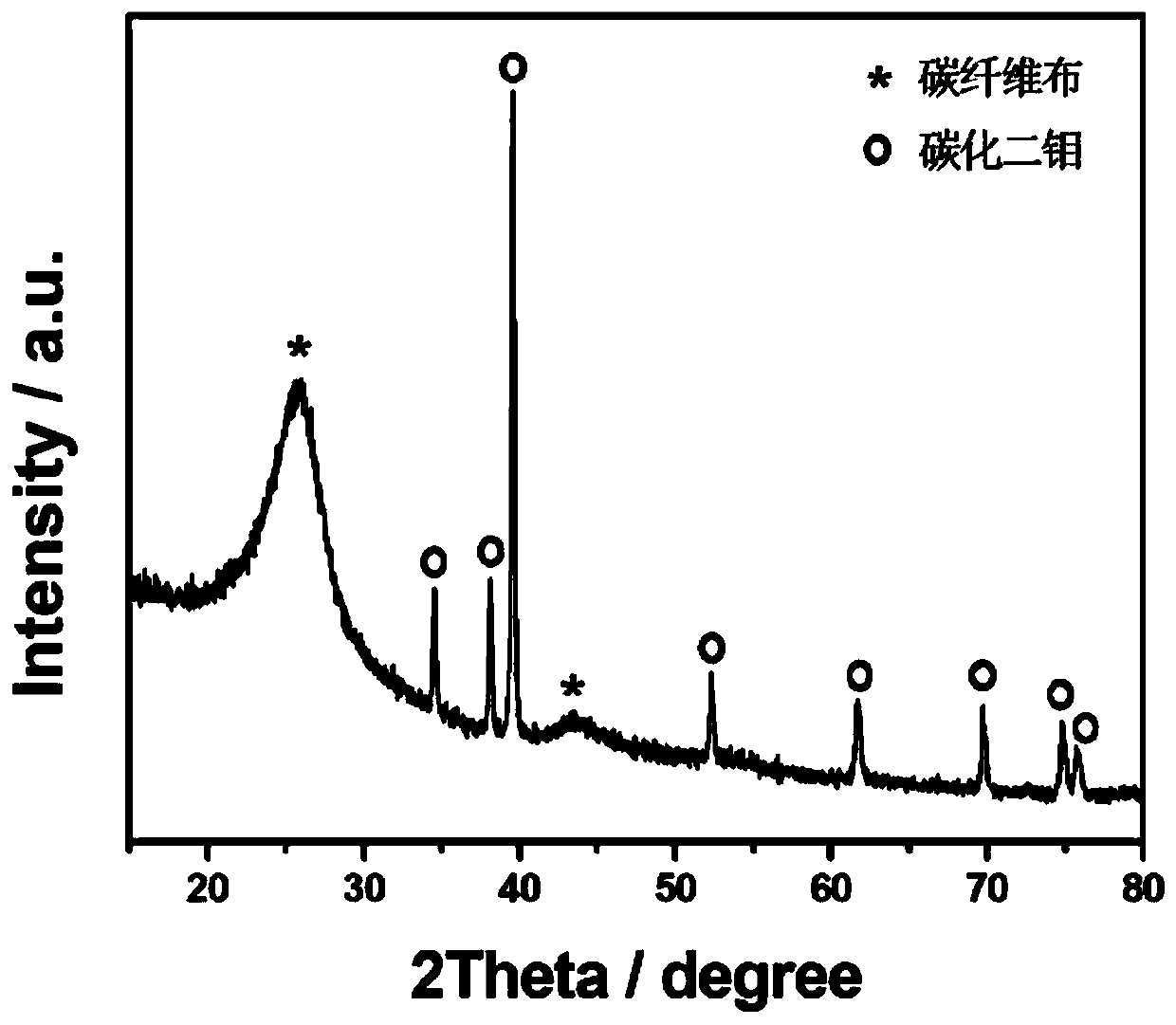

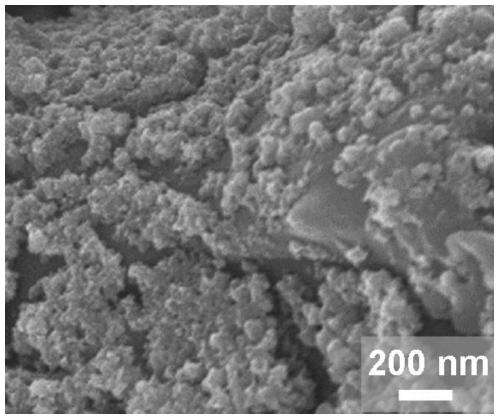

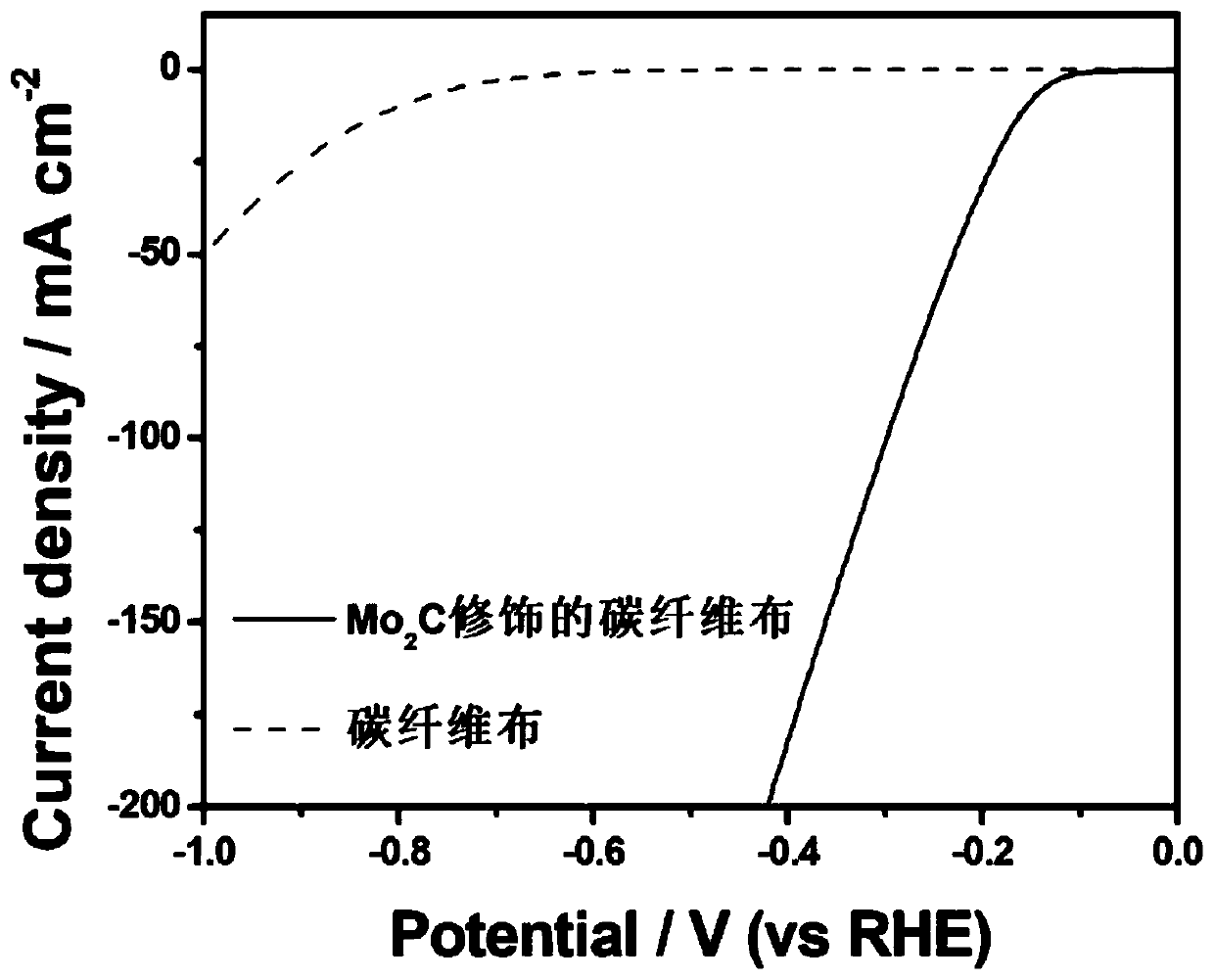

[0042] (1) Put 300mg of molybdenum disulfide into 300mL of absolute ethanol and ultrasonically disperse for 6 hours with an ultrasonic power of 160W to form a uniform suspension. 2 carbon fiber cloth surface (geometric area is about 18cm 2 ), after drying, a carbon fiber cloth with molybdenum disulfide uniformly loaded on the surface is obtained, and the loading capacity is about 2mg / cm (geo) 2 ; will subsequently carry the MoS 2 The carbon fiber cloth was placed in a crucible, and the temperature was raised to 300 °C at a rate of 5 °C / min under the protection of an argon atmosphere in a tube furnace and maintained for 1 hour.

[0043] (2) After the carbon fiber cloth is cooled naturally, it is fixed on one end of a molybdenum rod (3mm in diameter) with a molybdenum wire as the cathode, and a graphite rod as the anode, and the NaCl-KCl (molar ratio 1:1) molten salt at 700°C In the middle, 2.7V constant tank pressure electrolysis for 1 hour, figure 1 Schematic diagram of th...

Embodiment 2

[0046] (1) Put 300mg of molybdenum disulfide into 150mL of absolute ethanol and ultrasonically disperse for 6 hours with an ultrasonic power of 180W to form a uniform suspension. 2 The surface of the square graphite sheet (excluding the side area, the geometric area of the graphite sheet is about 16cm 2 ), after drying, a graphite sheet uniformly loaded with molybdenum disulfide on the surface is obtained, and the loading capacity is about 5mg / cm (geo) 2 ; will subsequently carry the MoS 2 The graphite sheet was placed in a crucible, and the temperature was raised to 150°C at a rate of 5°C / min under the protection of an argon atmosphere in a tube furnace and maintained for 3 hours.

[0047] (2) After the graphite sheet is cooled naturally, fix it on one end of a molybdenum rod (diameter 3mm) with a molybdenum wire as the cathode, and use the graphite rod as the anode, in NaCl-KCl (molar ratio 1:1) molten salt at 700°C , 2.9V constant tank pressure electrolysis for 45 minu...

Embodiment 3

[0050] (1) Put 300mg of molybdenum disulfide into 150mL of isopropanol and ultrasonically disperse for 6 hours with an ultrasonic power of 180W to form a uniform suspension. cm 3 On the grapefruit peel derived carbon foam (the geometric area of the large grapefruit peel carbon foam is 40cm 2 ), after drying, the grapefruit peel-derived carbon foam with molybdenum disulfide uniformly loaded on the surface was obtained, and the loading capacity was about 1.5mg / cm (geo) 2 ; will subsequently carry the MoS 2 The grapefruit peel-derived carbon foam was placed in a crucible, and the temperature was raised to 260°C at a rate of 3°C / min under the protection of nitrogen atmosphere in a tube furnace and kept for 2h.

[0051] (2) To be loaded with MoS 2 The grapefruit peel-derived carbon foam was cooled naturally, and then fixed on one end of a nickel-chromium rod (5mm in diameter) with a molybdenum wire as the cathode, and a graphite rod as the anode, in 700°C NaCl-KCl (molar rati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com