A kind of heavy oil hydrogenation method

A heavy oil hydrogenation and heavy oil technology, which is applied in chemical instruments and methods, hydrocarbon oil treatment, petroleum industry, etc., can solve the problems of large catalyst consumption and poor catalytic coke suppression performance, so as to promote high-efficiency conversion and improve catalytic hydrogenation activity , Improve the effect of inhibiting coke formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

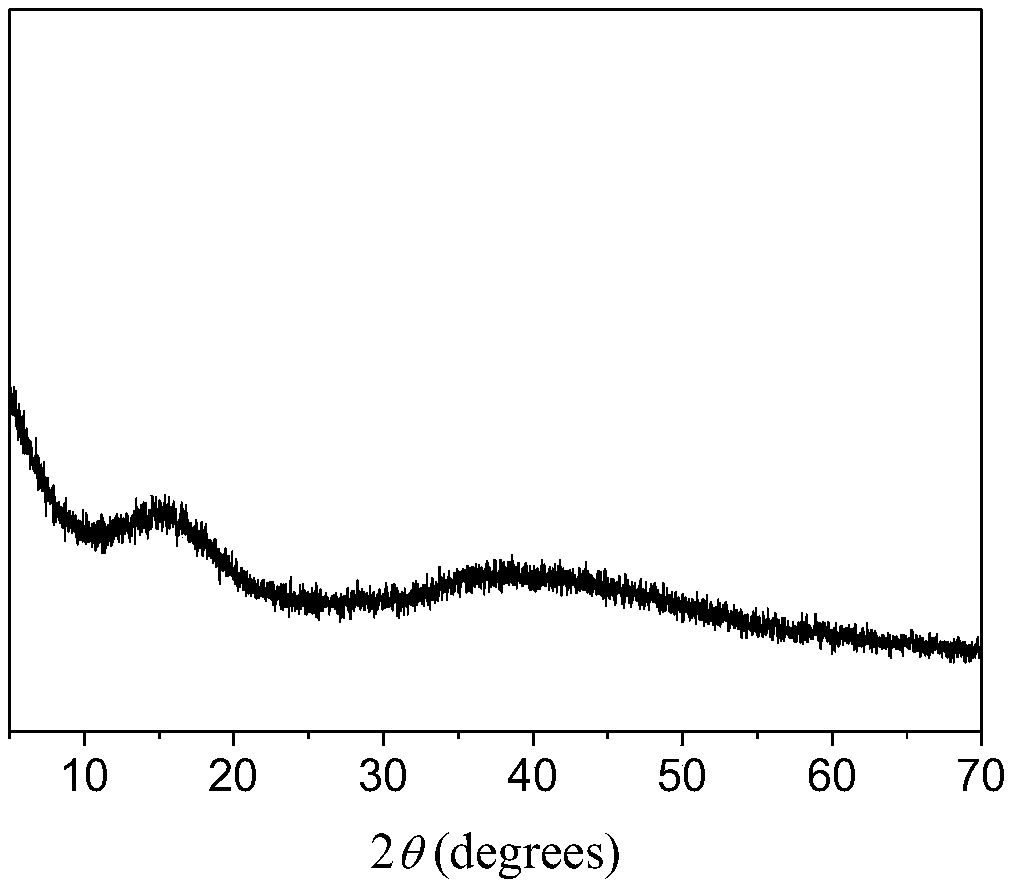

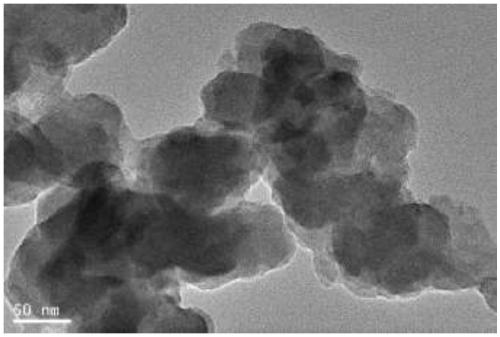

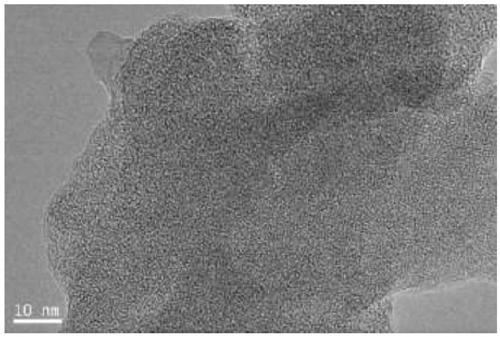

[0022] Prepare ammonium tetrathiomolybdate, hydroxylamine hydrochloride, and deionized water at a molar ratio of 1:2.0:120 to prepare an aqueous solution; stir and react at 45°C for 2 hours, then centrifuge, wash, and dry to obtain an amorphous nanomolybdenum disulfide catalyst .

Embodiment 2

[0024] Prepare ammonium tetrathiomolybdate, oxalic acid, and deionized water at a molar ratio of 1:1.5:280 to prepare an aqueous solution; stir and react at 70°C for 9.5 hours, then centrifuge, wash, and dry to obtain an amorphous nanomolybdenum disulfide catalyst .

Embodiment 3

[0026] Prepare ammonium tetrathiomolybdate, tartaric acid, and deionized water at a molar ratio of 1:2.5:70 to prepare an aqueous solution; stir and react at 50°C for 1.0h, then centrifuge, wash, and dry to obtain an amorphous nanomolybdenum disulfide catalyst .

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com