A kind of alcohol solvent hydrofining catalyst for olefin epoxidation reaction process and its preparation method and application

A technology for epoxidation reaction and hydrorefining, which is used in physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, preparation of organic compounds, etc., and can solve the problem of limited removal of harmful impurities and insufficient activity. , complex composition and other problems, to achieve the effect of good hydrogenation activity, improved reduction degree, and high impurity removal rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

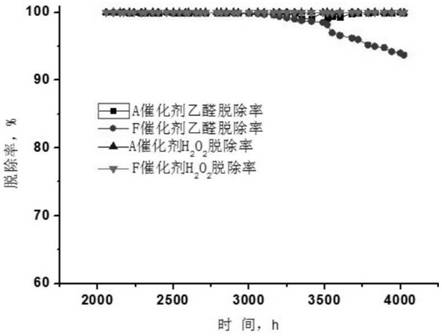

Examples

Embodiment 1

[0029] Preparation of catalysts:

[0030] (1) 10.0 grams of Ni (NO 3 ) 2 · 6h 2 O Soluble in deionized water to form impregnation fluid;

[0031](2) Put the impregnation liquid with the above-to-impregnated Al 2 O 3 Vectors (γ-al 2 O 3 The content is 40% by weight, δ-al 2 O 3 The content is 60 wt%) contact to impregnate Ni onto the carrier, then dried at 200 ° C for 10 h to obtain catalyst A.

[0032] Catalyst reduction and alcohol solvent hydrotreating:

[0033] Take 5.0 grams of catalyst C to fix the diameter of 12 mm, a fixed bed stainless steel reactor having a length of 90 cm, and the upper and lower ends of the reactor are filled with stone sand, intermediate filling catalyst to ensure the constant temperature zone of the catalyst in the reactor (if not specified, Both of the following examples use the reactor, the filling method is also consistent), in which the catalyst reduction is first performed, then the alcohol solvent hydrotreating of the olefin ring oxidation proces...

Embodiment 2

[0038] Preparation of catalysts:

[0039] (1) 10.0 grams of Ni (NO 3 ) 2 · 6h 2 O, 0.2 grams (NO) 3 ) 2 And 8.4 grams C 6 Hide 8 O 7 · H 2 O Soluble in deionized water to form impregnation fluid;

[0040] (2) Put the impregnation liquid with the above-to-impregnated Al 2 O 3 Vectors (γ-al 2 O 3 The content is 40% by weight, δ-al 2 O 3 The content was 60 wt%) to contact the Ni to the carrier, then dried at 200 ° C for 10 h, resulting in catalyst B, catalyst weight percent (wt%) as: 20 ni0.6Mn1.1c / al 2 O 3 .

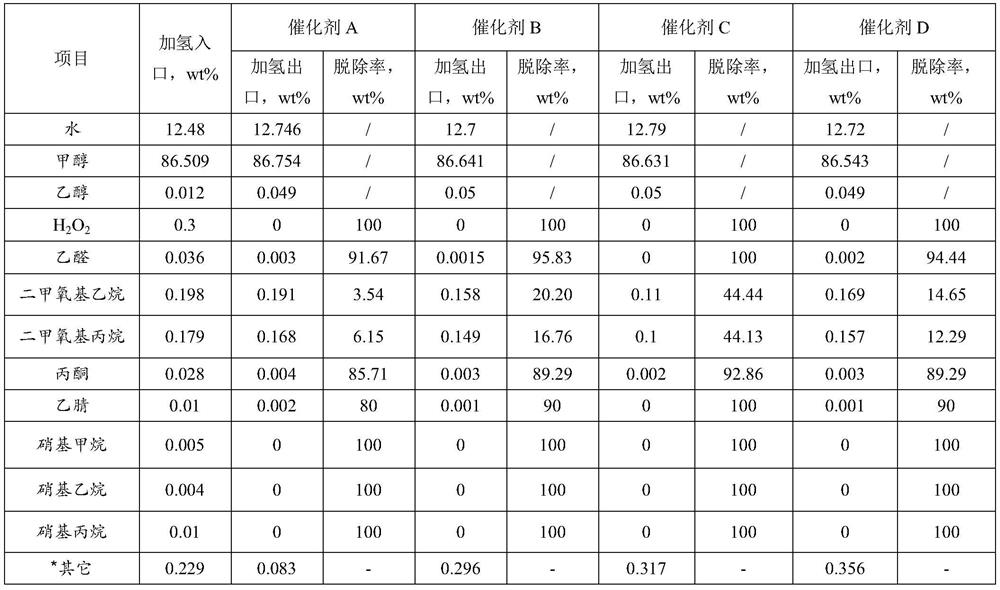

[0041] Catalyst reduction and alcohol solvent hydrotreating: Tongji 1

[0042] The composition of the raw material hydrogenation reaction is shown in Table 1.

Embodiment 3

[0044] Preparation of catalysts:

[0045] (1) 10.0 grams of Ni (NO 3 ) 2 · 6h 2 O, 1.0 grams MN (NO 3 ) 2 And 8.4 grams C 6 Hide 8 O 7 · H 2 O Soluble in deionized water to form impregnation fluid;

[0046] (2) Put the impregnation liquid with the above-to-impregnated Al 2 O 3 Vectors (γ-al 2 O 3 The content is 40% by weight, δ-al 2 O 3 The content was 60 wt%) to contact Ni, Mn, and citric acid onto the carrier, then dried at 200 ° C for 10 h, resulting in catalyst C, catalyst weight percent (wt%) as: 20 ni3Mn1.1c / al 2 O 3 .

[0047] Catalyst reduction and alcohol solvent hydrotreating: Tongji 1

[0048] The composition of the raw material hydrogenation reaction is shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com